Introduction

Temperature is one of the most fundamental and widely measured parameters in industrial processes. Nearly 50% of all process control applications involve temperature monitoring, and accurate temperature measurement is essential for product quality, equipment safety, energy efficiency, and overall plant reliability.

Because temperature cannot be sensed directly, it must be measured through the physical properties of materials that vary with thermal changes—such as electrical resistance, thermal expansion, or thermoelectric effects.

This article provides a clear, professional overview of the main temperature measurement technologies used today, their operating principles, typical applications, strengths, and limitations.

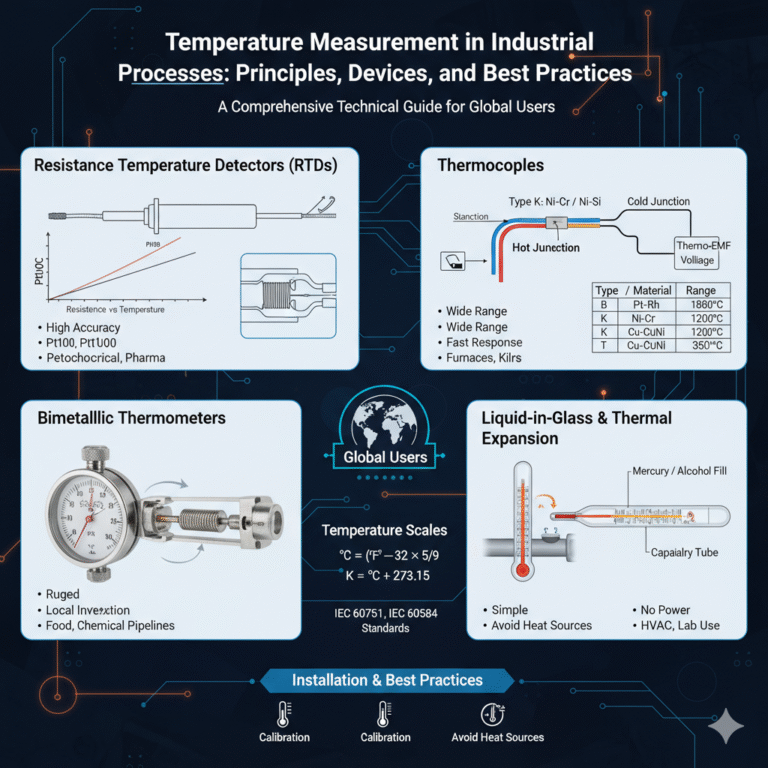

Temperature Scales and Conversions

Three temperature scales are commonly used in industrial and scientific settings:

Celsius (°C) — widely used in most regions

Fahrenheit (°F) — primarily used in the United States

Kelvin (K) — the standard thermodynamic scale used in engineering and research

Their relationships are:

°C = (°F − 32) × 5/9

K = °C + 273.15

Understanding these scales and conversions is essential for international engineering teams and instrumentation calibration.

Classification of Common Temperature Measurement Technologies

Industrial temperature instruments fall into four principal categories:

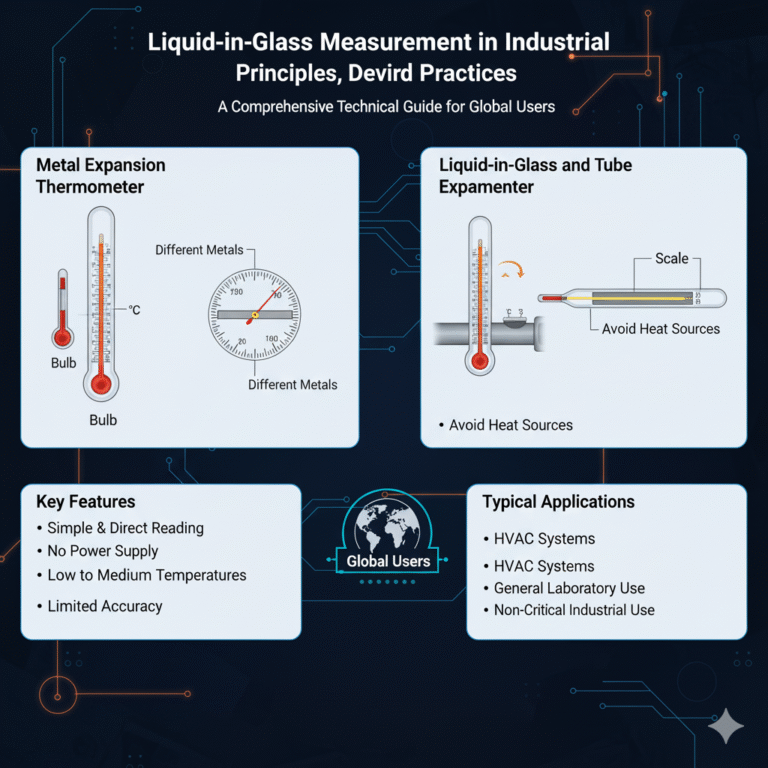

1. Liquid-in-Glass and Thermal Expansion Thermometers

Principle

These devices rely on the thermal expansion of liquids (alcohol or mercury) or metals when temperature changes.

Key Features

Simple and direct reading

No power supply required

Suitable for low to medium temperature applications

Limited accuracy and not suitable for advanced process control

Typical Applications

Boilers

HVAC systems

General laboratory use

Non-critical industrial pipelines

2. Bimetallic Thermometers

Principle

A bimetallic thermometer contains two bonded metal strips with different thermal expansion coefficients. As temperature changes, the strip bends, driving the pointer on a dial.

Advantages

Rugged and inexpensive

Fast response

Suitable for on-site indication

Limitations

Lower accuracy (Class 1.0, 1.5, or 2.5)

Not ideal for data logging or high-precision control

Applications

Food processing

Chemical pipelines

Mechanical equipment monitoring

Outdoor temperature indication

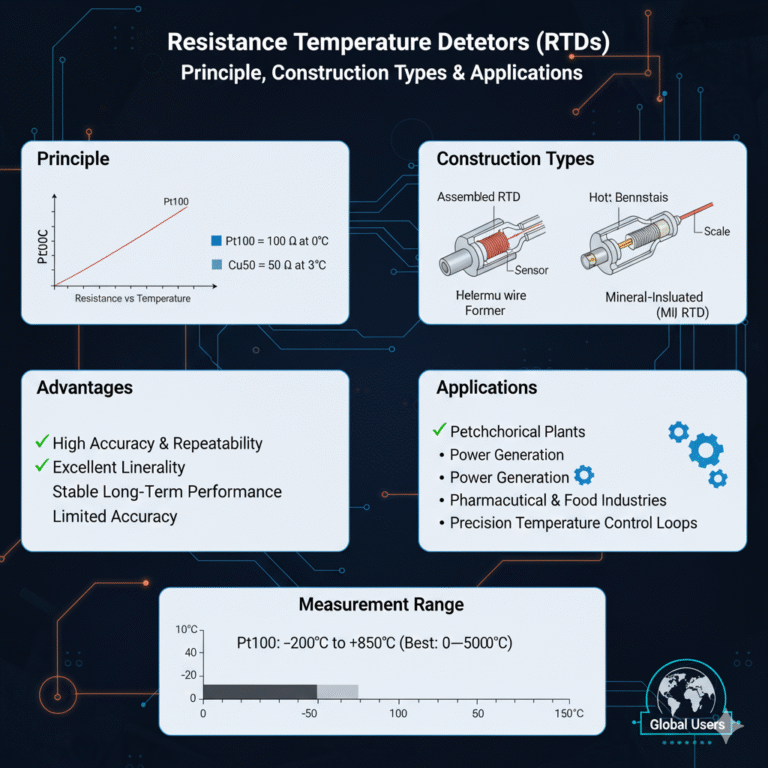

3. Resistance Temperature Detectors (RTDs)

RTDs—particularly Pt100 and Pt1000—are the most widely used sensors where high accuracy and stability are required.

Principle

RTDs utilize the predictable change in electrical resistance of metals (usually platinum) with temperature.

For example:

Pt100 = 100 Ω at 0°C

Cu50 = 50 Ω at 0°C

Measurement Range

Pt100: –200°C to +850°C (best performance within 0–500°C)

Cu50: –50°C to +150°C

Advantages

High accuracy and repeatability

Excellent linearity

Stable long-term performance

Construction Types

Assembled RTDs: with protection tubes

Mineral-insulated (MI) RTDs: flexible, vibration-resistant, faster response

Applications

Petrochemical plants

Power generation

Pharmaceutical and food industries

Precision temperature control loops

4. Thermocouples

Thermocouples are the preferred sensors for high-temperature and wide-range industrial applications.

Principle

When two dissimilar metals are joined together, they generate a voltage (thermo-EMF) proportional to the temperature difference between the measurement junction and the reference junction.

Thermocouples are defined by their type—representing the metal materials used:

| Type | Material Composition | Typical Range |

|---|---|---|

| B | Pt-Rh30 / Pt-Rh6 | 600–1800°C |

| S | Pt-Rh10 / Pt | 0–1600°C |

| K | Ni-Cr / Ni-Si | –200–1200°C |

| E | Ni-Cr / Cu-Ni | –200–900°C |

| T | Cu / Cu-Ni | –200–350°C |

| J | Fe / Cu-Ni | –40–750°C |

Advantages of Thermocouples

Extremely wide measuring range

Fast response

Simple structure and durable

Suitable for long cable runs

Use of Compensation Cables

Each thermocouple type requires matching extension wires to maintain accuracy. Using the wrong compensation cable can cause significant measurement errors.

Typical Industrial Applications

Furnaces and kilns

Refinery heaters

Glass and steel production

High-temperature reactors

Exhaust and flue gas measurement

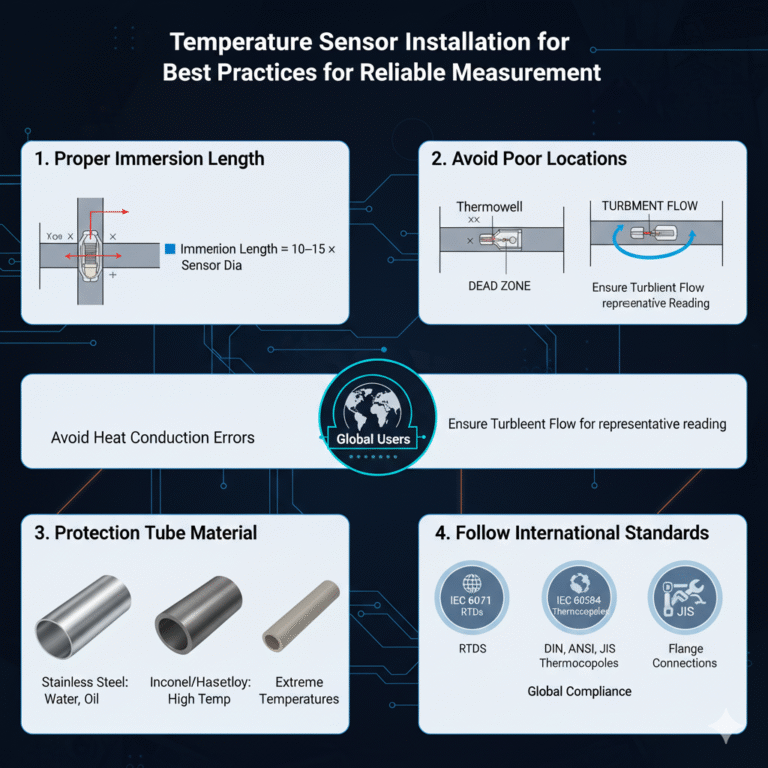

Installation Considerations for Temperature Sensors

Correct installation is essential for achieving reliable temperature measurements. Key recommendations include:

1. Proper immersion length

Sensors must be immersed deep enough in the process medium to avoid heat conduction errors.

General guideline: Immersion length ≥ 10–15 times the sensor diameter

2. Avoid installation near heat sources or dead zones

Ensure turbulent flow around the sensor to obtain a representative temperature profile.

3. Choose the correct protection tube material

Depending on media:

Stainless steel for water, oil, general chemicals

Inconel or Hastelloy for corrosive or high-temperature environments

Ceramic tubes for extreme temperatures

4. Use thermal paste or proper contact surfaces for surface-mount sensors.

5. Follow international standards

Sensors and installation should comply with:

IEC 60751 for RTDs

IEC 60584 for thermocouples

DIN, ANSI, or JIS flange connection standards

Accuracy, Calibration, and Common Error Sources

Accurate temperature measurement depends not only on choosing the right sensor but also on proper calibration and maintenance.

Common Error Sources

Poor contact or insufficient insertion depth

Selection of incorrect thermocouple type

Using unmatched extension cables

Oxidation or corrosion of sensor materials

Thermal lag due to oversized protection tubes

Electrical noise in long cable runs

Calibration Best Practices

Perform periodic calibration based on process requirements

Use certified equipment traceable to national standards

For thermocouples, check the condition of the measurement junction regularly

For RTDs, test insulation resistance and lead wire integrity

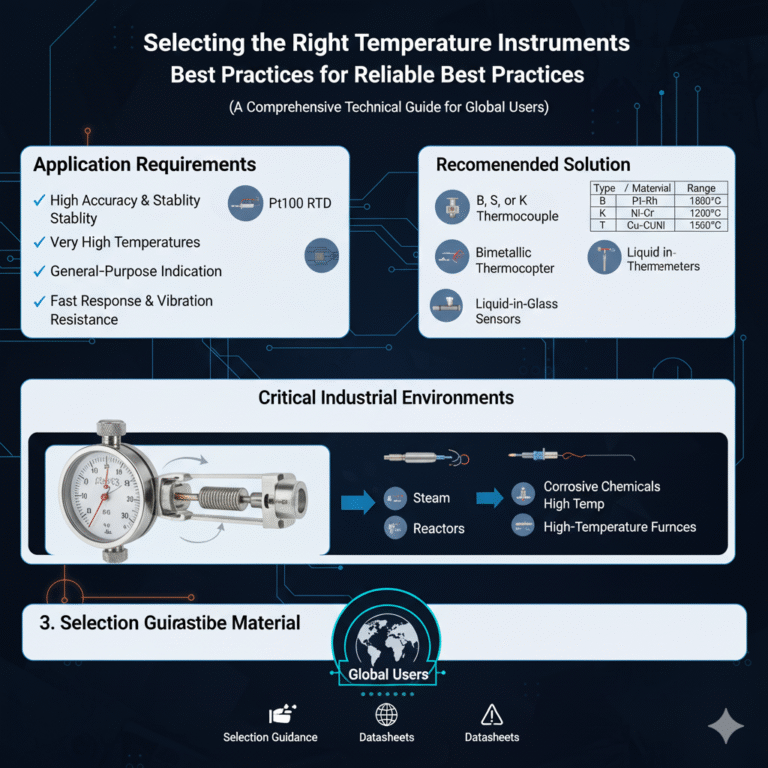

Selecting the Right Temperature Instrument

Choosing the proper sensor depends on the process conditions:

| Requirement | Recommended Solution |

|---|---|

| High accuracy and stability | Pt100 RTD |

| Very high temperatures | B, S, or K thermocouple |

| General-purpose pipeline indication | Bimetal thermometer |

| Low-cost applications | Liquid-in-glass thermometer |

| Fast response & vibration resistance | Mineral-insulated sensors |

For critical industrial environments—such as steam, corrosive chemicals, reactors, and high-temperature furnaces—thermocouples and MI-RTDs are generally preferred.

Conclusion

Temperature is a critical variable in nearly every industrial process, and choosing the right measurement technology is essential for accuracy, safety, and efficiency. By understanding the principles of RTDs, thermocouples, bimetal thermometers, and thermal expansion devices—as well as applying proper installation and calibration practices—engineers can significantly improve process performance and reliability.

If you require selection guidance, datasheets, or customized temperature probes (RTD, thermocouple, high-temperature sensors, or sanitary designs), our technical team is ready to support your application needs.