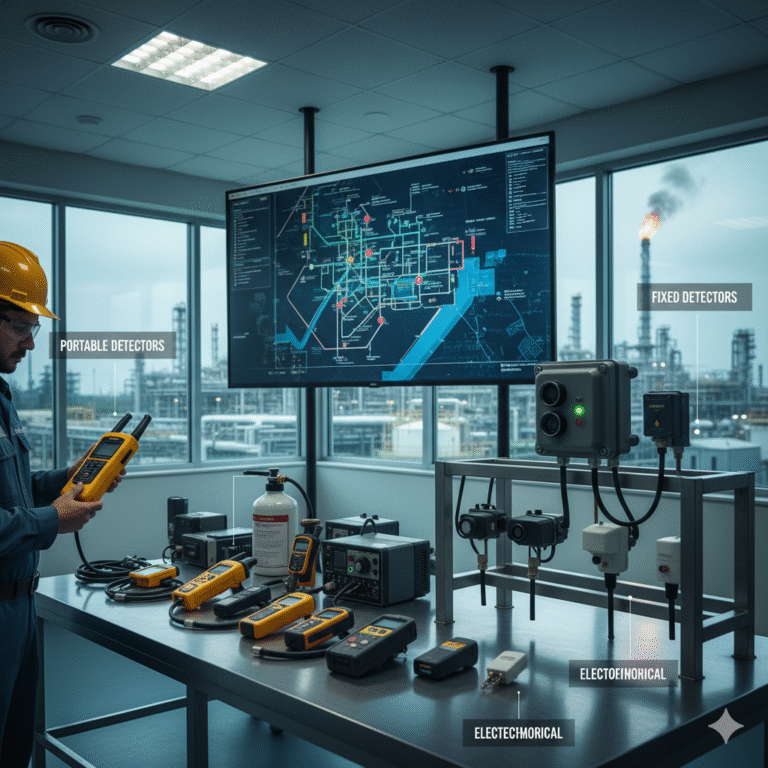

In gas detection and safety-instrumented applications, the choice of signal transmission method is not just a design preference—it directly affects the Safety Integrity Level (SIL) and the overall reliability of the safety protection layer. As fieldbus technologies become more common in process plants, a frequently debated question has emerged:

Can a Gas Detection System (GDS) use communication-based signals such as FF, PROFIBUS-PA, Modbus, or TCP/IP?

This article provides a systematic answer based on three key industry standards and explains the underlying technical reasons why communication signals are currently not recommended for SIS/GDS safety functions.

1. Background: Why the Signal Type Matters in a Safety System

Safety Instrumented Systems (SIS), including GDS, require:

High availability

Deterministic response time

Low probability of failure on demand (PFD)

Independence from non-safety systems

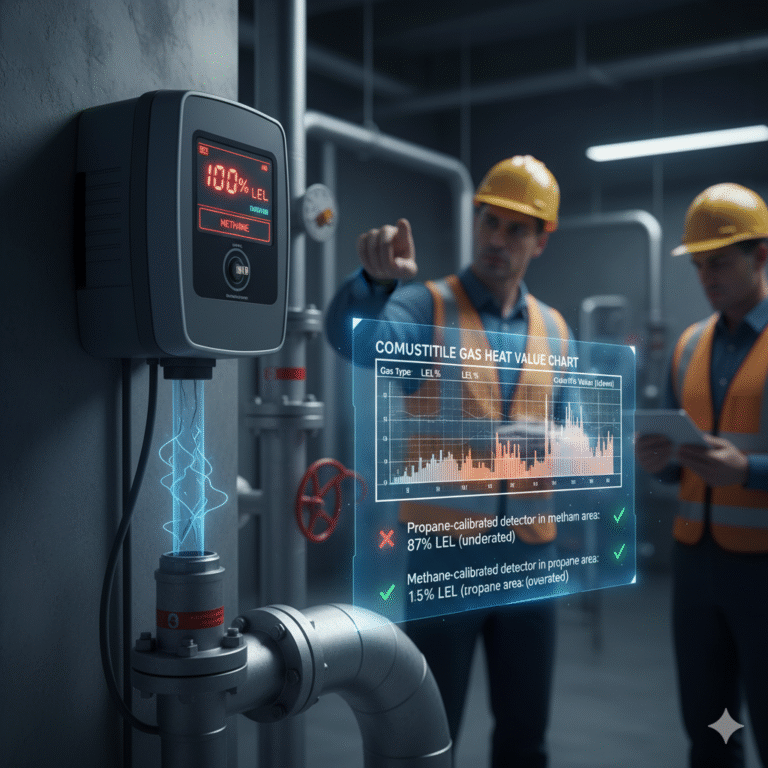

Communication-based protocols—although powerful in process control—introduce uncertainties such as packet delays, protocol handling, bus congestion, and network disturbances. These risks conflict with the deterministic behavior required for safety loops.

Therefore, several national and industrial standards provide clear restrictions.

2. Review of Relevant Standards

2.1 GB/T 50770-2013 — Design Specification for Safety Instrumented Systems

Clause 6.1.5:

“Measuring instruments shall not use fieldbus or other communication methods as input signals for SIS.”

Clause 6.1.2:

“4–20 mA with HART is recommended as the signal form for safety-related transmitters.”

Interpretation

A 4–20 mA analog loop provides:

Deterministic response

Simple failure detection (open/short circuit)

Independence from network data traffic

Communication protocols require encoding/decoding, token passing, and polling, making them inherently slower and less predictable than direct analog current loops.

2.2 SH/T 3188-2017 — PROFIBUS Control System Design Specification

Clause 4.8:

SIS, GDS, CCS, MMS, BMS and other safety-related systems shall not use PROFIBUS-PA bus technology.

Interpretation

A typical PROFIBUS-PA segment allows multiple devices to share the same physical cable.

This structure introduces a serious single point of failure, for example:

Cable damage

Power feed interruption

A single field device failure causing the entire bus to halt

Electromagnetic interference

If a bus failure occurs, all sensors on the segment lose signal simultaneously, which is unacceptable for safety protection layers.

2.3 HG/T 22820-2024 — Engineering Specification for Chemical SIS

Clause 6.1.3:

Communication signals and wireless signals are susceptible to internal and external interference, and currently cannot meet the safety and availability requirements for interlock inputs. Therefore, SIS input signals shall not use communication protocols such as FF, PROFIBUS-PA, MODBUS-RTU, or TCP/IP.

Interpretation

Wireless and wired communication protocols introduce:

Unpredictable latency

Packet loss

Network congestion

Router/switch dependency

Cybersecurity risks

These vulnerabilities make them unsuitable as primary safety inputs.

3. Technical Reasons Why Communication Signals Are Not Allowed

Based on the above standards, the restrictions are consistent.

Key engineering considerations include:

✔ 1. Response Time Is Not Deterministic

Digital protocols require:

Data encapsulation/decapsulation

Bus arbitration

Packet queuing

CRC verification

This results in non-deterministic delays.

✔ 2. Shared Bus = Single Point of Failure

One faulty device or cable failure may collapse the entire segment.

✔ 3. Higher Potential for Electromagnetic and Network Interference

Especially in refineries, petrochemical plants, offshore platforms, and power stations.

✔ 4. Safety Loops Must Remain Independent from Control Loops

Fieldbus networks are typically shared with basic process control systems (BPCS), which reduces safety independence.

✔ 5. Compliance Requirements

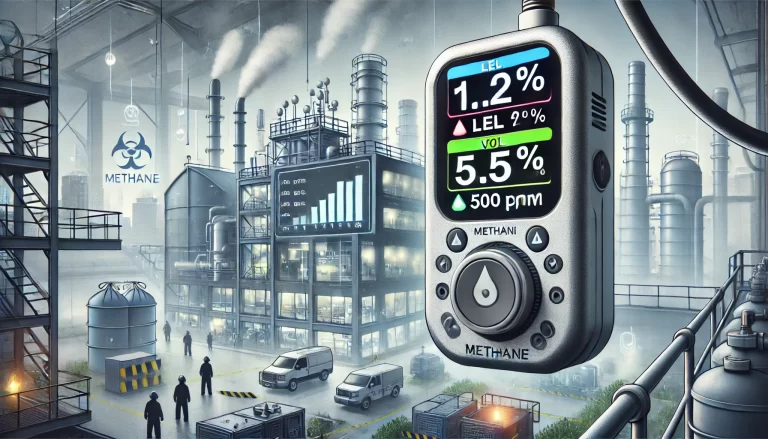

To achieve SIL1–SIL3 performance levels, analog 4–20 mA loops remain the industry baseline.

4. Conclusion

Based on GB/T 50770, SH/T 3188, and HG/T 22820, as well as practical engineering considerations, the conclusion is clear:

Current safety standards do not allow GDS or SIS input signals to use fieldbus communication or wireless communication protocols.

Protocols such as FF, PROFIBUS-PA, Modbus-RTU, and TCP/IP cannot yet meet the determinism, availability, and SIL requirements of safety protection functions.

At present, the 4–20 mA analog signal (with optional HART) remains the most reliable, safe, and standards-compliant method for GDS input signal transmission.