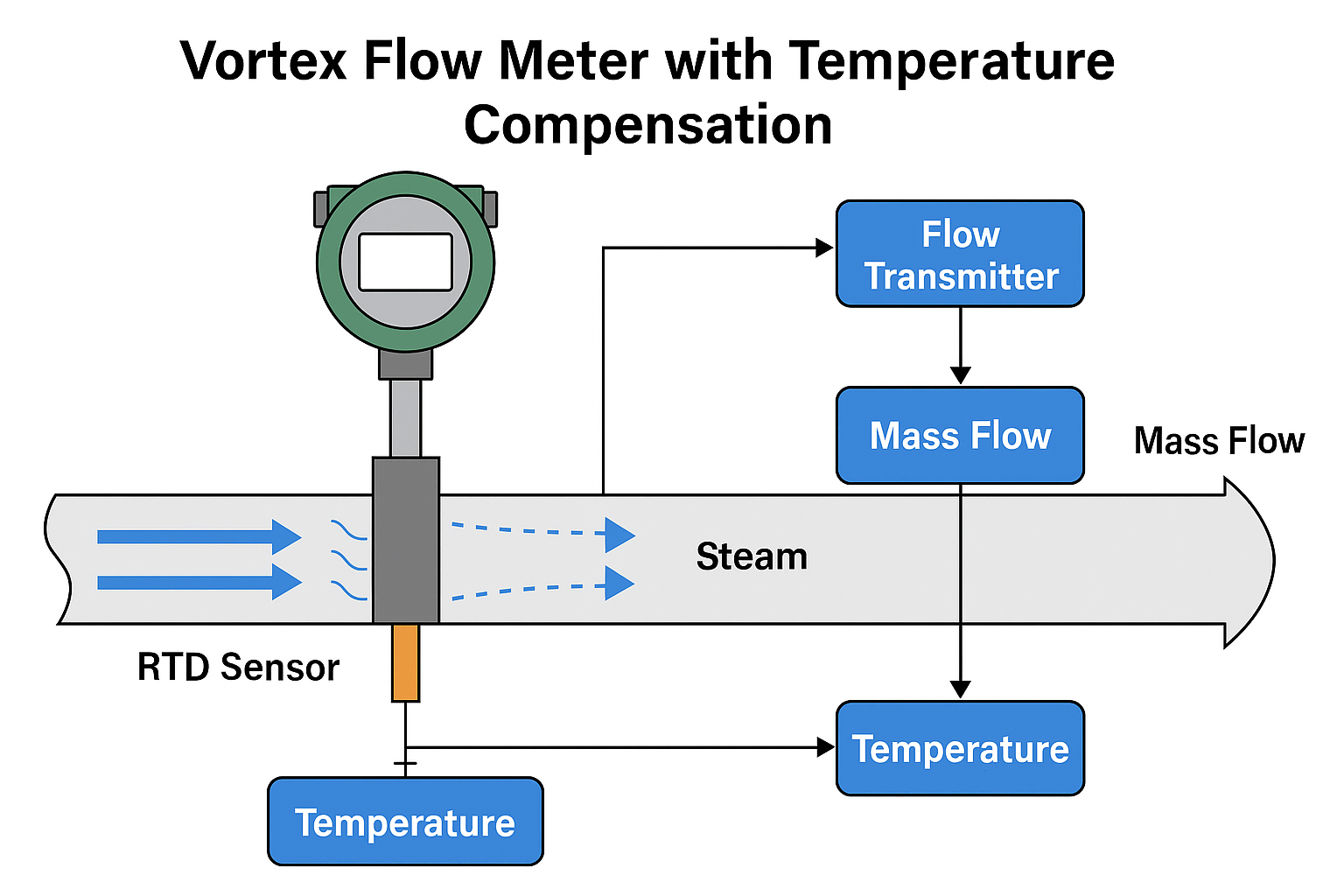

Vortex flow meters have long been appreciated for their wide applicability, no moving parts, and reasonable cost. They are commonly used for steam, compressed air, gases, and clean liquid measurement.

However, in many industrial sites, vortex meters are often described as “unstable, inaccurate, or difficult to maintain.”

In most cases, these problems do not come from the instrument itself, but from selection, installation, and application mismatches.

This article clarifies the real performance boundaries of vortex flow meters and explains how to select, install, and maintain them correctly — using practical formulas and real-world cases.

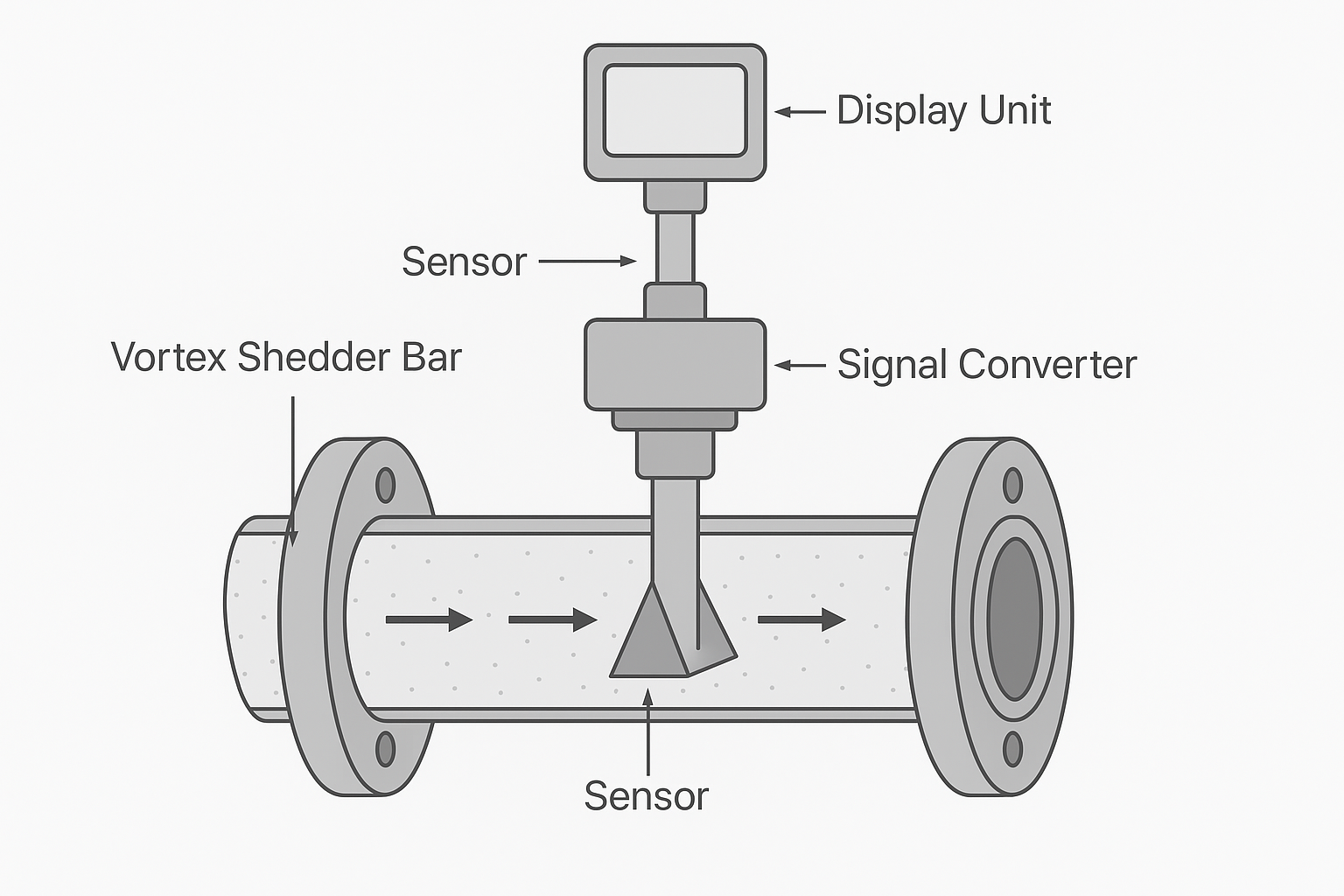

1. Core Principle: Vortex Generation and Frequency

A bluff body inside the flow channel generates alternating vortex shedding.

The vortex frequency f is proportional to the fluid velocity v:

Where:

St – Strouhal number (constant for given Re range)

d – Diameter of the bluff body

Therefore:

Flow measurement accuracy heavily depends on stable vortex formation.

Anything that changes flow stability will directly affect measurement.

2. Correct Selection Is the Foundation

2.1 Match Measuring Range to the Application

The actual operating flow must fall within the meter’s 20%–80% of full-scale range (high-accuracy products can extend to 10%–90%).

Below 20%: vortex signals weaken → meter displays zero or fluctuates

Above 80%: vortex may distort → sensor overload / long-term drift

Full-scale range selection rule:

If no full-scale meets both — pipe size must be reduced.

2.2 Pipe Diameter Must Match Flow Velocity

Vortex meters require sufficient flow velocity to generate stable vortices.

| Medium | Recommended Velocity |

|---|---|

| Liquid | 0.5 – 10 m/s |

| Gas / Air | 5 – 60 m/s |

| Steam | 20 – 70 m/s |

Too low → vortex cannot form → 0 reading / unstable

Too high → high noise/vibration → signal distortion

If velocity is too low in a large pipeline:

→ Use concentric reducers to downsize to a smaller meter.

2.3 Material and Process Compatibility Checklist

| Condition | Selection Requirement |

|---|---|

| Temperature up to 300℃ | Standard vortex meter |

| High temperature 300–450℃ | High-temperature probe & extended neck |

| Corrosive fluids | 316L or Hastelloy sensor body |

| High viscosity (>10 mm²/s) | Not recommended (vortex weakens) |

3. Installation Determines Stability

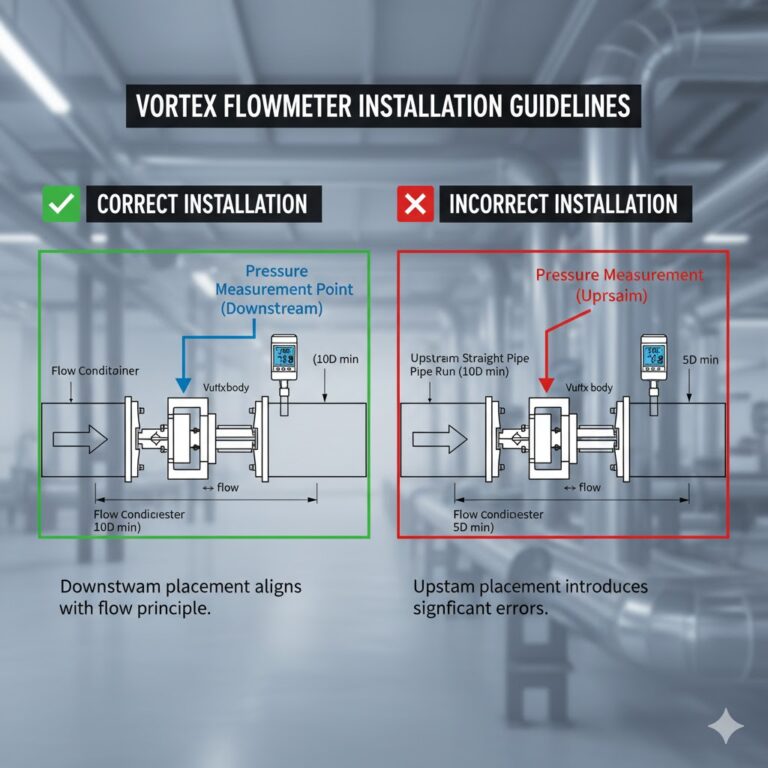

3.1 Straight Pipe Length Matters

To ensure uniform flow profile:

| Upstream (Inlet) | Downstream (Outlet) |

|---|---|

| ≥ 10D | ≥ 5D |

If upstream has valves, elbows, pumps → increase to 15D.

3.2 Use Concentric Reducers When Reducing Pipe Size

Only concentric reducers are acceptable

Eccentric reducers create asymmetric flow → major error

Standard requirement:

Reducer Length≥1.5Dsmaller pipe

3.3 Installation Direction

Horizontal pipe: sensor upward (avoid liquid accumulation)

Vertical pipe: flow must be bottom → top (guarantee full pipe)

4. Maintenance and Verification

| Item | Frequency | Key Point |

|---|---|---|

| Sensor cleaning | Every 3–6 months | Remove deposits to avoid frequency distortion |

| Cable and grounding check | Monthly | Ensure stable signal transmission |

| Zero-point check | Annually | No flow → reading must be zero |

5. Case Studies

Case 1 — Incorrect Range & Pipe Size

Pipeline: DN200

Actual flow: 8–35 m³/h (water)

DN200 velocity at 8 m³/h = 0.28 m/s → Too low → Vortex unstable

Solution:

Reduce to DN150

Select full-scale 0–50 m³/h

Result: reading stability improved, accuracy < ±2.5%

Case 2 — Wrong Reducer Causing Asymmetric Flow

Fruit juice pipeline using eccentric reducer

Error increases with flowrate (8–12%)

Solution:

Replace with standard concentric reducer

Add ≥15D upstream straight pipe

Result: error decreases to ±2.5%

6. Practical Conclusion

Vortex flow meters are not fading because they are inaccurate.

They become problematic when:

Flow range is mismatched

Flow velocity is too low

Incorrect reducers are used

Straight pipe requirements are ignored

When properly selected and installed, vortex meters are reliable, durable, and cost-effective — especially for steam, compressed air, and clean liquids.

However:

| Medium | Recommended Meter |

|---|---|

| Clean stable liquid | Vortex / Electromagnetic |

| Steam | Vortex (ideal choice) |

| Natural gas & compressed air | Vortex or Rotary / Differential pressure |

| Slurry / conductive fluids | Electromagnetic flow meter |