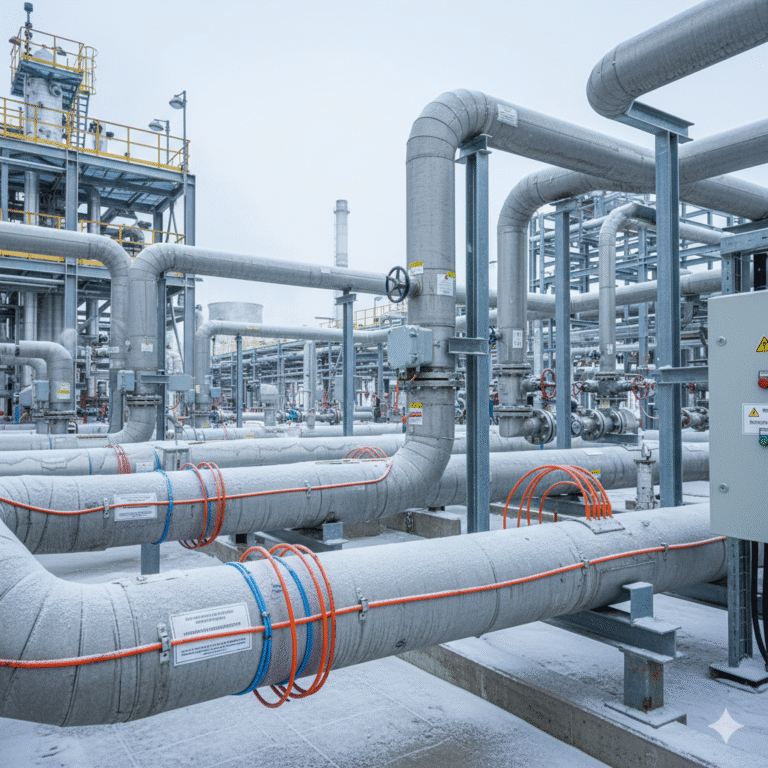

1. Overview of Electric Heat Tracing Systems

Electric heat tracing systems are widely used in chemical, petrochemical, coal-to-chemicals, refining, and water treatment industries to prevent pipeline freezing, maintain process temperature, and ensure stable plant operation during cold weather. Based on heating characteristics and construction, heat tracing cables are mainly classified into:

Self-regulating (Self-limiting) Heat Tracing Cables

Constant Wattage Heat Tracing Cables

MI (Mineral-Insulated) Heat Tracing Cables

Each type features different temperature capabilities, installation requirements, investment levels, and maintenance characteristics.

2. Self-Regulating Heat Tracing Principle

The core heating element of a self-regulating heat tracing cable is a PTC (Positive Temperature Coefficient) conductive polymer. The electrical resistance increases as the temperature rises, automatically reducing output power. This allows the system to adjust heat output according to ambient and pipe temperature without external control.

Working Process

Cold Start

At low temperatures, resistance decreases

Startup current is relatively high (typically 1.5–2.5 times rated current)

Temperature Stabilization

As the pipe warms up, resistance increases

Current decreases accordingly

Heat output automatically stabilizes

Dynamic Self-Adjustment

When ambient temperature drops again, the cable automatically increases heat output

Ensures continuous anti-freezing and temperature maintenance

This self-regulating mechanism prevents overheating, enhances safety, and reduces energy consumption.

3. Why Tripping Occurs During Sudden Temperature Drop

Common Field Observation

When ambient temperature falls below approximately −5°C, certain heat tracing circuits may trip intermittently.

Root Causes

| Cause | Explanation |

|---|---|

| Higher Startup Current in Cold Conditions | Low temperature reduces conductor resistance, increasing inrush current |

| Delayed Current Attenuation | More heat loss to environment slows warm-up, extending high-current period |

| Breaker Thermal Protection Activation | Sustained high current heats the breaker bimetal element, triggering trip |

Key Insight

This phenomenon is not due to cable failure, but due to prolonged current plateau, not just a short current spike.

4. Field Factors That Increase Tripping Risk

Damaged or waterlogged insulation layer → Rapid heat loss

Circuits designed too close to the breaker capacity limit

Use of C-type breakers instead of recommended D-type breakers for high inrush loads

Large pipeline surface area / heavy wind exposure

5. Installation and Critical Details

Heat Tracing Application Methods

| Method | Application | Notes |

|---|---|---|

| Linear Installation | Standard pipelines | Ensure full surface contact and consistent fixing |

| Spiral Winding | Large diameter or high heat demand | Maintain uniform pitch, avoid excessive tension |

| Overlapping (Self-regulating only) | Valves, pumps, flanges | Constant wattage cables must not overlap to avoid overheating |

Tail End Treatment (Critical for Reliability)

The tail end must be sealed with certified termination kits

Conductors must not be shorted

In hazardous areas, Ex-rated junction box and termination kits are mandatory

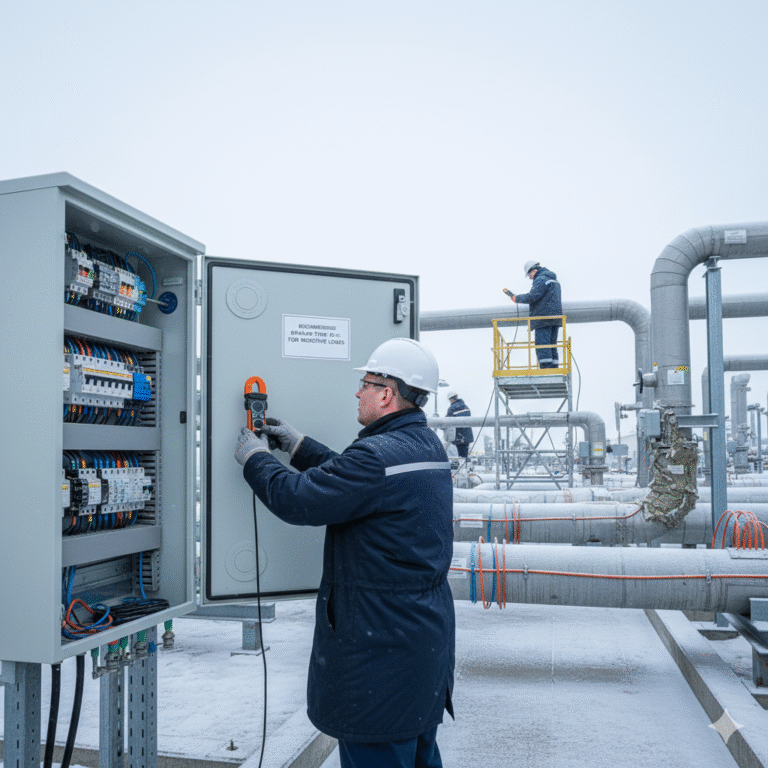

6. Winter Inspection and Maintenance Guidelines

Routine Operation Checkpoints

| Inspection Item | Method | Acceptance Criteria |

|---|---|---|

| Operating Current | Clamp meter measurement | Stable and within design value |

| Surface Temperature | Touch or IR thermometer | Uniform heating, no noticeable cold spots |

| Junction Boxes | Visual inspection | Dry, sealed, no condensation or corrosion |

Special Inspection During Cold Weather

Increase inspection frequency during nighttime and early morning

Focus on previously problematic circuits

Repair damaged insulation immediately to avoid heat loss amplification

7. Solutions to Frequent Tripping

| Problem Scenario | Recommended Corrective Action |

|---|---|

| Frequent trips during temperature drop | Replace C-type breaker with D-type breaker |

| Circuit load near rated limit | Split circuit or increase power supply segmentation |

| High heat loss or damaged insulation | Repair / retrofit insulation layer |

| Aging or incorrect connectors | Replace with certified termination kits |

8. Conclusion

Self-regulating heat tracing is a critical safeguard for winter operation in industrial facilities. Understanding its temperature-electricity interaction, ensuring proper installation, and implementing systematic inspection and maintenance are key to preventing winter-related failures such as circuit tripping and pipeline freezing.

A well-managed heat tracing system directly contributes to:

Plant safety

Continuous production stability

Reduced energy consumption

Reduced emergency maintenance costs