1. FAT: Factory Acceptance Test

FAT (Factory Acceptance Test) is a comprehensive inspection and testing process carried out by the manufacturer before the equipment leaves the factory. The goal is to ensure that the product meets the contract, design, and technical specifications.

Key Features of FAT:

Location: Conducted at the manufacturer’s or supplier’s factory.

Participants: Manufacturer’s quality inspection and commissioning team, along with the customer’s representative (and possibly third-party inspectors).

Test Content:

Equipment appearance, dimensions, materials, and serial numbers

Functionality tests (ensuring operation as specified)

Control logic and software validation

Safety protections and interlock checks

Pre-shipment performance data recording

Purpose: To ensure the equipment meets contractual and design requirements before shipping, preventing major issues on-site.

Result: A written report is usually produced, and the customer signs off, confirming that the equipment is ready for shipment.

2. SAT: Site Acceptance Test

SAT (Site Acceptance Test) is the final acceptance test conducted at the customer’s site after the equipment has been delivered, installed, and commissioned.

Key Features of SAT:

Location: Conducted at the customer’s site (production facility, data center, construction site, etc.).

Participants: The customer leads the process, with the supplier/contractor assisting and sometimes a third-party inspector.

Test Content:

Inspection of equipment installation quality

Integration testing of wiring, interfaces, software, and other systems

Performance testing under real operating conditions

Safety operation and emergency shutdown tests

Continuous operation trials (e.g., 24-hour or 72-hour trials)

Purpose: To verify that the equipment can operate as intended in the real-world environment and meets production requirements.

Result: After successful SAT completion, the equipment is formally handed over to the customer and enters the warranty period.

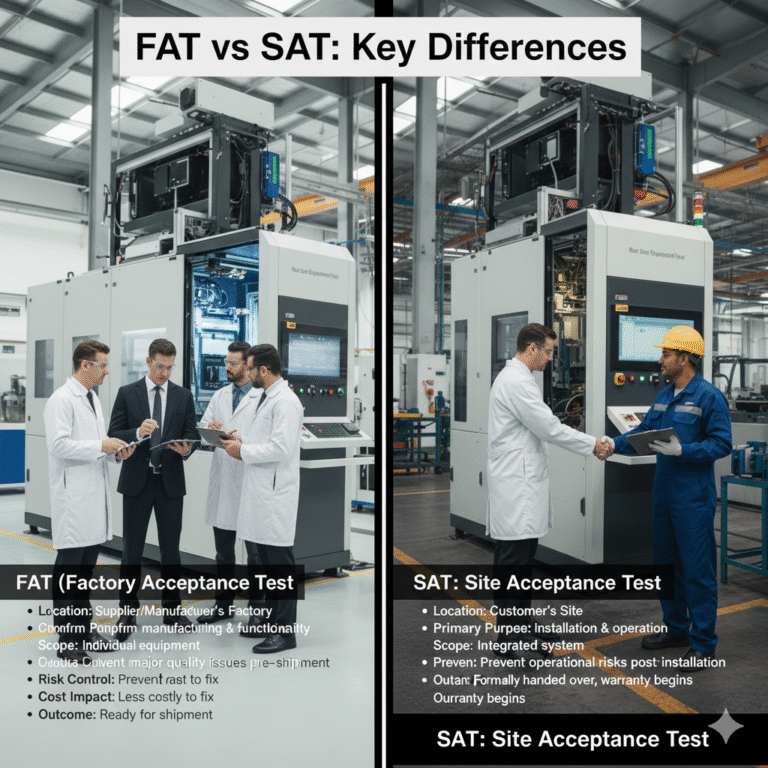

3. FAT vs SAT: Key Differences and Relationship

| Comparison Point | FAT (Factory Acceptance Test) | SAT (Site Acceptance Test) |

|---|---|---|

| Test Location | Supplier/Manufacturer’s Factory | Customer’s Site |

| Primary Purpose | Confirm that equipment manufacturing and functionality meet design specifications, and it is ready for shipment. | Confirm that the equipment installation is correct and it functions as intended in the real environment. |

| Scope of Testing | Individual equipment functionality and basic performance tests. | Integration testing, performance testing in real-world conditions. |

| Risk Control | Prevent major quality issues before shipment. | Prevent operational risks after the equipment is in use. |

| Cost Impact | Issues found during FAT are generally less costly to fix. | Issues found during SAT are more costly (involve disassembly, downtime). |

| Participants | Supplier leads, with the customer’s representative as a witness. | Customer leads, with supplier assistance. |

| Outcome | Once passed, equipment is ready for shipment. | Once passed, equipment is formally handed over and enters warranty. |

4. Simple Explanation:

FAT is like the pre-delivery inspection of a car at the factory—ensuring everything works as expected before delivery.

SAT is like taking the car for a test drive after it’s delivered to your home—testing how it performs in real-life conditions, ensuring it meets your needs.