Overview of Explosion-Proof Classification

Explosion-proof classification is a globally recognized standard system used to define the safe operational capabilities of electrical equipment in explosive environments. The primary purpose is to ensure that the equipment cannot act as an ignition source (e.g., sparks or high temperatures) that could trigger an explosion.

Key Elements of Explosion-Proof Classification

An explosion-proof classification label is like the “ID card” of the equipment, clearly indicating its safe operational range. A complete explosion-proof label includes the following key components:

| Core Element | Symbol Example | Explanation |

|---|---|---|

| Explosion-Proof Symbol | Ex | International standard indicating the equipment is explosion-proof certified. |

| Explosion-Proof Type | d, e, i, p, m, o, q | Specifies the protective measures taken to prevent ignition in explosive environments. |

| Equipment Category | I, II, III | Indicates the type of environment where the equipment is suitable (mines, gas, dust environments). |

| Gas Group | IIA, IIB, IIC | For Category II devices, indicates the explosiveness of gases/steam. |

| Temperature Group | T1 – T6 | Maximum surface temperature the equipment can reach during operation and failure conditions. |

| Protection Level | Ga/Da, Gb/Db, Gc/Dc | Defines the likelihood of the equipment acting as an ignition source and its protective level. |

Explosion-Proof Type Explanation

Explosion-proof type is the core of the explosion-proof technology. Common types include:

| Explosion-Proof Type | Symbol | Technical Principle | Application |

|---|---|---|---|

| Flameproof Type | d | The outer shell can withstand internal explosions and prevent flames from escaping. | Motors, switch cabinets, control boxes. |

| Increased Safety Type | e | Safety features added to components that do not normally generate sparks or arcs during operation. | Junction boxes, lighting fixtures, transformers. |

| Intrinsic Safety Type | i | Limits circuit energy to prevent sparks or heat from igniting the explosive environment. | Instruments, sensors, control systems. |

| Pressurized Type | p | Maintains internal pressure higher than external pressure using protective gas. | Analyzers, large control cabinets. |

| Encapsulated Type | m | Encapsulates potential spark-producing parts in resin to isolate them from the explosive mixture. | Electronic components, small switches. |

Temperature Group Explanation

The temperature group is a critical safety indicator for explosion-proof equipment. It specifies the maximum surface temperature that the equipment can reach during normal operation or specified failure conditions. This temperature must always be below the minimum ignition temperature of the surrounding combustible gases or dusts.

| Temperature Group | Max Surface Temp (°C) | Representative Gases | Ignition Temp (°C) |

|---|---|---|---|

| T1 | ≤ 450 | Hydrogen, acrylonitrile | 560 |

| T2 | ≤ 300 | Acetylene, ethylene | 305 |

| T3 | ≤ 200 | Gasoline, diesel | 220-260 |

| T4 | ≤ 135 | Acetaldehyde, diethyl ether | 140-160 |

| T5 | ≤ 100 | No typical gas | – |

| T6 | ≤ 85 | Carbon disulfide, nitroglycerin | 95-100 |

Key Considerations in Explosion-Proof Equipment Selection

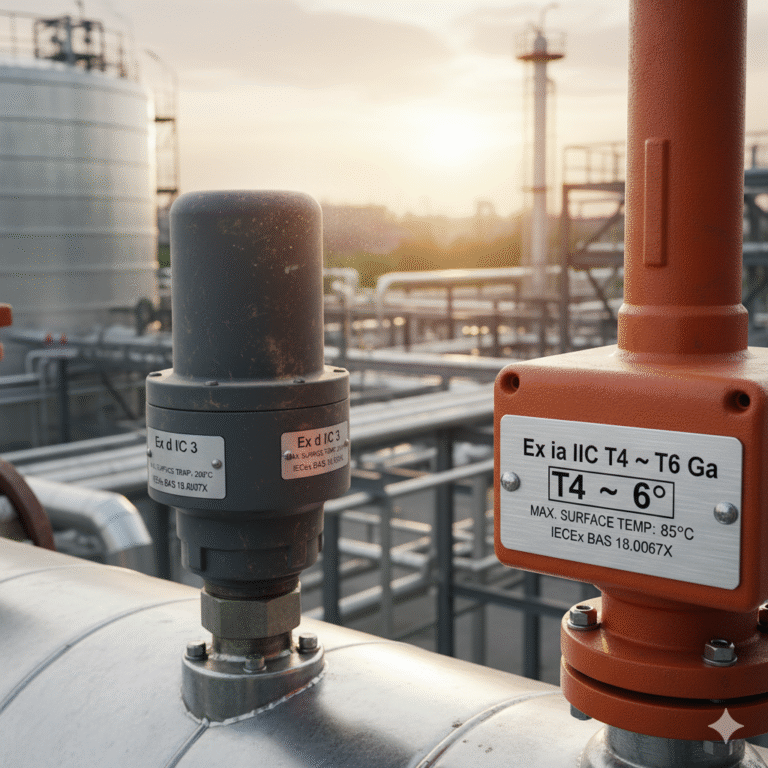

Example of Temperature Class: A device labeled as T4 means its surface temperature will not exceed 135°C, even under the harshest conditions.

Selection Rule: Always ensure that the temperature class (e.g., T4) corresponds to a maximum temperature lower than the ignition temperature of the gases in the environment. For example, if carbon disulfide (ignition temperature: 95°C) is present, the device must be rated T6 (maximum temperature 85°C).

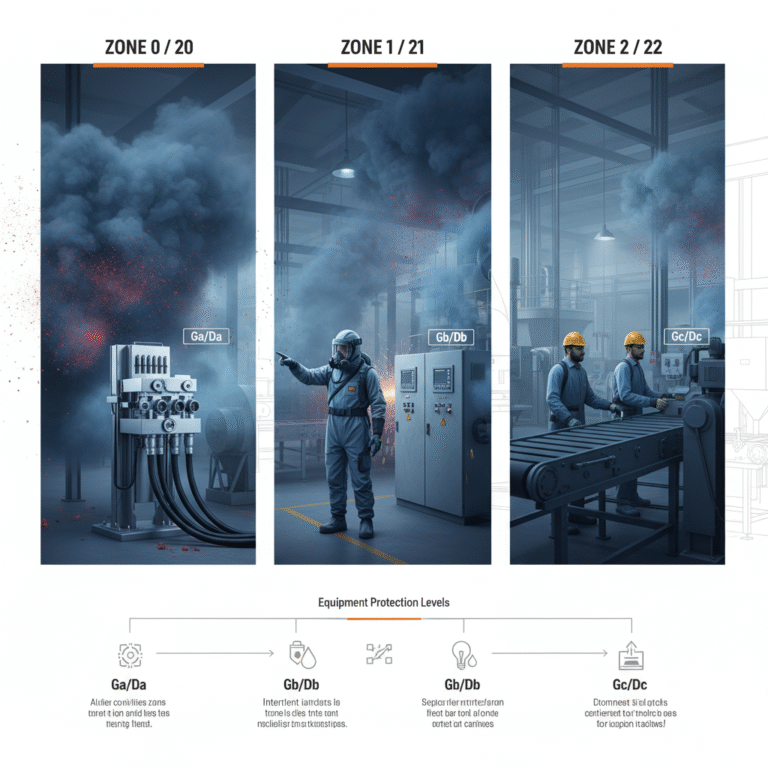

Hazard Zone Classification and Equipment Selection

Explosion-proof equipment selection starts with classifying hazardous areas based on the likelihood and duration of explosive environments. Hazardous locations are divided into different zones:

| Zone | Gas Environment Definition | Dust Environment Definition | Applicable EPL (Equipment Protection Level) |

|---|---|---|---|

| 0/20 | Explosion-proof gas mixture is present continuously or for long periods | Explosion-proof dust cloud is present continuously or for long periods | Ga/Da |

| 1/21 | Explosion-proof gas mixture is likely to occur under normal operation | Explosion-proof dust cloud is likely to occur under normal operation | Gb/Db |

| 2/22 | Explosion-proof gas mixture is unlikely to occur, or only briefly | Explosion-proof dust cloud is unlikely to occur, or only briefly | Gc/Dc |

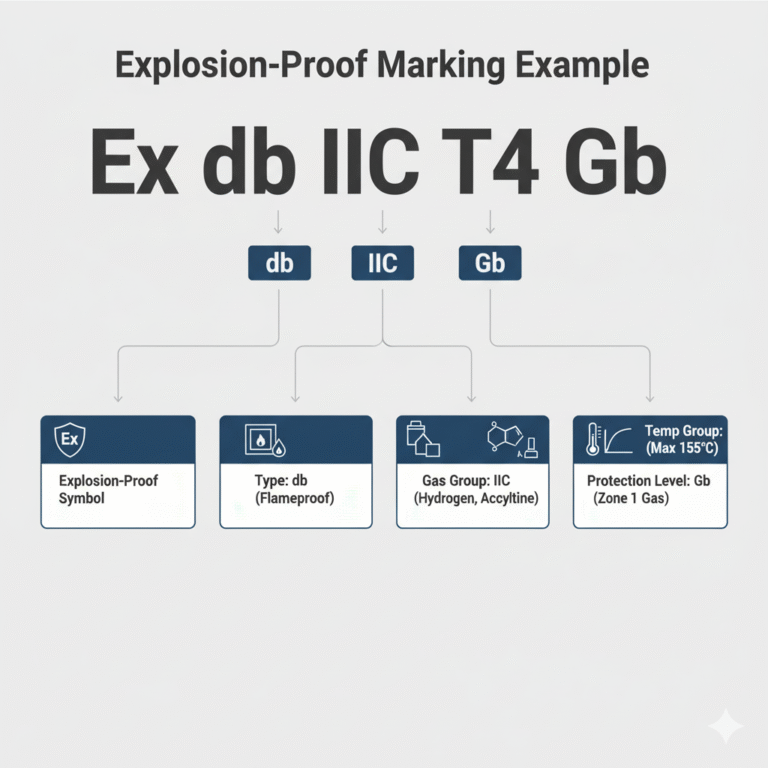

Explosion-Proof Marking Example

Let’s decode the label Ex db IIC T4 Gb:

Ex: Explosion-proof symbol

db: Explosion-proof type (flameproof type)

IIC: Gas group (can be used in the most dangerous gas environments, including hydrogen and acetylene)

T4: Temperature group (surface temperature will not exceed 135°C)

Gb: Equipment protection level (suitable for gas environment Zone 1)

Typical Application Scenarios in Coal Chemical Industry

Dust Explosion Hazardous Environments

Typical areas: coal powder preparation, coal belt conveyors, coal storage bins

Hazard zone: mostly Zone 21 or 22

Explosion-proof requirements: Equipment protection level typically Db, explosion-proof marking should correspond to IIIC conductive dust (e.g., coal dust).

Gas Explosion Hazardous Environments

Typical areas: coke ovens, chemical recovery (e.g., crude benzene, coal tar processing), gas purification zones

Hazard zone: Zone 1 or 2 based on gas release frequency

Explosion-proof requirements: Select gas group based on gas type (IIA, IIB, IIC), equipment protection level based on zone classification, e.g., Gb for Zone 1.

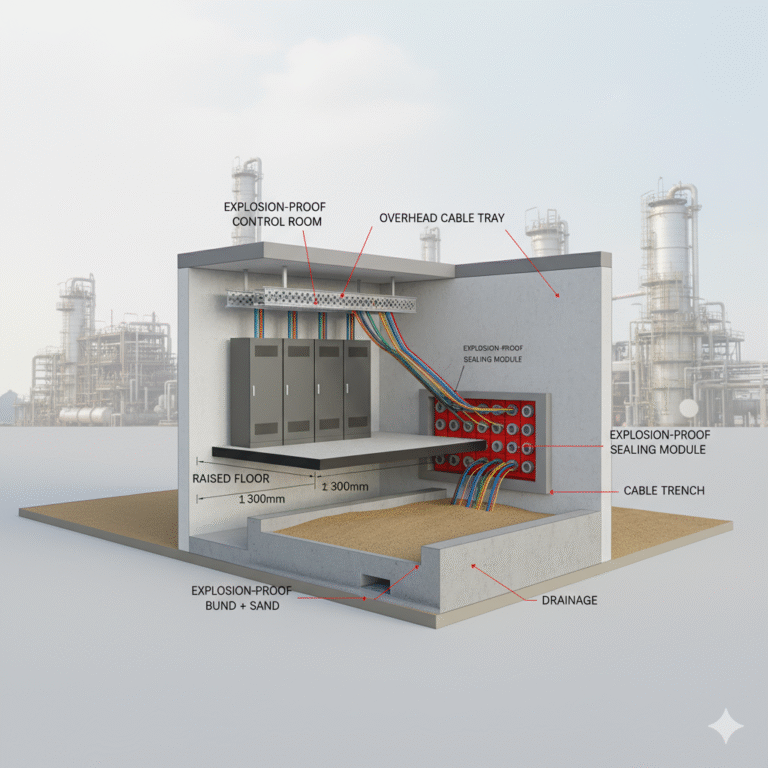

Mixed Hazardous Environments

Many coal chemical sites contain both combustible gases and dust.

Strategy: Select instruments that meet both gas and dust explosion-proof requirements or mitigate dust accumulation through engineering controls (e.g., cleaning, ventilation).

Standards and Regulations

China’s explosion-proof standards system consists of foundational standards, equipment-specific standards, and site safety guidelines, forming a complete chain of guidance from risk identification and equipment design to on-site application.

Main National Standards:

GB/T 3836.1-2021: Explosive environments—Part 1: General requirements for equipment

GB/T 3836.2-2021: Explosive environments—Part 2: Equipment protected by flameproof enclosures “d”

GB/T 3836.4-2021: Explosive environments—Part 4: Equipment protected by intrinsic safety “i”

GB/T 3836.31-2021: Explosive environments—Part 31: Equipment protected by dust ignition-proof enclosures “t”

GB 46031-2025: Explosion-proof technical specifications for combustible dust process systems (Effective from February 1, 2026)

GB 12710-2024: Coking safety regulations (Effective from July 1, 2025)

Equipment Selection Logic

Identify Hazardous Areas: Determine if the site is Zone 0, 1, or 2 (gas) or Zone 20, 21, or 22 (dust).

Identify Hazardous Materials: Determine the type of gas or dust, its gas group, and ignition temperature.

Match Equipment: Select equipment where the EPL rating matches the hazard zone, and ensure the gas/dust group and temperature class “cover” or exceed the site’s hazardous materials.