I. IP Protection Rating: Definition and Practical Applications

The IP Protection Rating (Ingress Protection Rating) is a standard set by the International Electrotechnical Commission (IEC) to define the effectiveness of electrical enclosures against foreign objects (such as tools, dust, and fingers) and liquids (water). It is commonly used for electrical devices, lamps, distribution boxes, and outdoor cabinets.

IP Code Structure

The IP code consists of the letters “IP” followed by two digits:

The first digit indicates the level of protection against solid objects (0-6).

The second digit indicates the level of protection against water (0-9K).

First Digit: Protection Against Solid Objects

| Digit | Protection Description | Typical Applications |

|---|---|---|

| 0 | No protection | Ordinary indoor electrical panels. |

| 1 | Prevents objects ≥50mm | Large equipment enclosures. |

| 2 | Prevents objects ≥12.5mm | Household appliances. |

| 3 | Prevents objects ≥2.5mm | Industrial instruments and control panels. |

| 4 | Prevents objects ≥1mm | Factory equipment in dusty environments. |

| 5 | Dust-protected | Areas requiring dust protection but not fully sealed. |

| 6 | Dust-tight | Communication devices in desert areas. |

Second Digit: Protection Against Water

| Digit | Protection Description | Typical Applications |

|---|---|---|

| 0 | No protection | Dry indoor environments. |

| 1 | Prevents vertically falling drops of water | Ceiling areas prone to condensation. |

| 2 | Prevents water drops at a 15° tilt | Light outdoor rain environments. |

| 3 | Prevents sprayed water at a 60° angle | Outdoor lights and vehicles. |

| 4 | Prevents splashing water in any direction | Kitchen appliances, outdoor cabinets. |

| 5 | Prevents water jets in any direction | Building facades and industrial devices requiring cleaning. |

| 6 | Prevents powerful water jets | Marine equipment, areas washed by seawater. |

| 7 | Prevents temporary immersion in water up to 1 meter depth | Portable devices (smartwatches, speakers). |

| 8 | Prevents continuous immersion in water under agreed conditions | Underwater devices, buried sensors. |

| 9K | Resists high-pressure, high-temperature water jets | Food, chemical, and automotive equipment requiring steam cleaning. |

Key Differences:

IPX5/IPX6 vs. IPX7/IPX8: The former protects against water jets (impact force), while the latter protects against immersion in water (static water pressure).

IPX9K: Specifically designed for high-pressure, high-temperature cleaning, often seen in industrial cleaning environments.

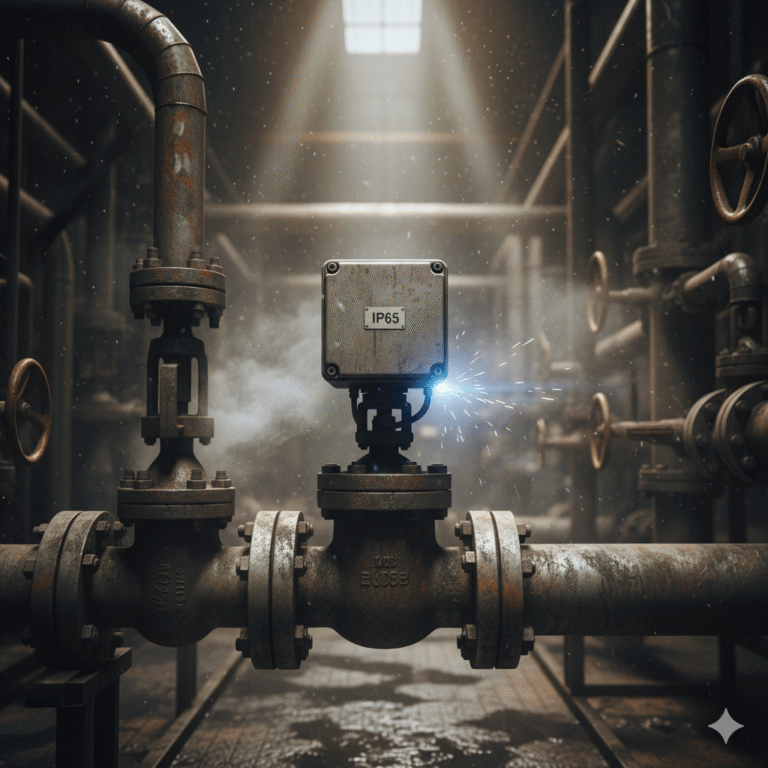

II. Practical Case: IP65 Valve Locator Malfunctions in Steam Environments

1. Site Conditions and Fault Description

Equipment: Steam flow control valve locator in a gasification furnace.

Protection Rating: IP65.

Fault Symptoms: Feedback failure and output fluctuations in the locator, causing instability in the valve, which affects production.

Environmental Characteristics: Coal dust, periodic coal dust flushing, steam medium.

2. Root Cause Systematic Analysis

Initial troubleshooting revealed a complex issue, indicating that this was not merely an “incorrect equipment selection” but rather a systemic protection failure. The fault chain is as follows:

Source (Process Leakage): Leakage in the valve’s gland packing led to continuous leakage of steam into the outer insulation layer.

Amplifier (Environmental Effect): The leaked liquid steam was heated by the high-temperature valve body and insulation, converting it into more penetrative, higher-pressure steam, which continuously impacted the locator housing.

Seal Failure (Installation and Sealing Issues): The gland head was not tightened, which is the most critical weak link in the protective barrier. IP65 protection assumes an intact enclosure, but the loose gland head created a breach.

External Pressure (Operational Procedure): Routine coal dust flushing contributed additional moisture, causing “inside-out” pressure, which overwhelmed the sealing ability of the IP65 rating.

3. Core Problem: Is IP65 Enough?

Conclusion: IP65 is excellent under static and standard test conditions but inadequate in dynamic, complex environments like the one described here.

Theoretical vs. Practical: IP65 is tested using ambient temperature water, not high-temperature steam. Steam molecules are smaller and more penetrating, especially when cooled and condensed. Its impact on the enclosure is far more damaging than under standard test conditions.

Systemic Flaw: IP protection is based on a fully intact device. In this case, the issues of a loose gland head and gland packing leakage undermined the protection level.

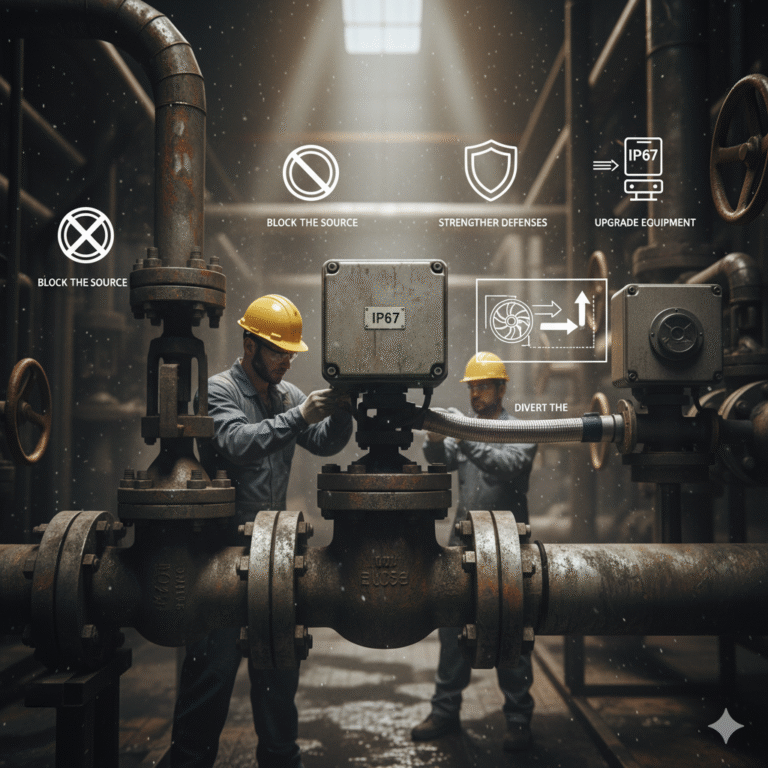

III. From Theory to Practice: Systematic Solutions

To address this issue, a systematic approach—block, defend, divert, and upgrade—should be followed.

1. Block the Source (Priority Action)

Eliminate Process Leakage: Repair the valve gland packing to prevent further leakage. This is the root cause, and without fixing this, other measures will have limited effect.

Ensure Proper Sealing: Tighten all gland heads according to torque specifications and use the appropriate sealing rings.

2. Strengthen Defenses (Multi-layer Protection)

Check Internal Seals: Ensure the housing cover’s gasket is not aged or damaged and is uniformly tightened.

Add External Protection (Cost-Effective):

On-Site Measures: Reinforce the cable entry seal by adding an explosion-proof flexible conduit between the cable and gland. This creates an additional barrier that effectively prevents moisture from entering through the gland head.

3. Divert the Environment (Optimize Local Microenvironment)

Communicate Operational Procedures: Advise the workshop to avoid directing water jets onto the control valve and insulation during routine flushing.

Improve Insulation Design: Inspect and repair any damage to the insulation, ensuring its integrity and waterproofing to prevent water accumulation.

On-Site Measures: Install a forced cooling and insulation system:

Explosion-proof axial fans: Position fans to blow air directly onto the locator to reduce internal condensation and mitigate steam effects.

Insulation plates: Add insulation plates between the locator and the high-temperature valve body to reduce heat radiation and weaken the thermal impact on the locator.

4. Upgrade Equipment (Long-Term Plan)

If the above measures still do not resolve the issue or to ensure higher reliability, consider upgrading the equipment:

Upgrade to a Higher IP Rating: Use IP66/IP67 rated locators that provide better sealing and can withstand harsher environments.

Opt for Specialized Products: Seek locators specifically designed for use in “steam environments” or those with airtight designs.

Summary

While the IP protection rating is a crucial factor in equipment selection, it should not be viewed as a permanent solution. Engineers must:

Understand the precise meaning of IP ratings and the boundary conditions of their testing.

Adopt a systematic protection mindset, considering each stage from process to installation to the external environment.

Follow a scientific troubleshooting path: prioritize fixing the fundamental process and installation leaks, then enhance external protection, and finally evaluate equipment upgrades to efficiently address complex field problems.