In Safety Instrumented Systems (SIS), Safety Integrity Levels (SIL) are crucial for ensuring that Safety Instrumented Functions (SIF) meet the necessary risk reduction requirements. This article focuses on the Layer of Protection Analysis (LOPA) method, which is widely used to determine the appropriate SIL for a specific SIF in industrial applications.

Introduction to Layer of Protection Analysis (LOPA)

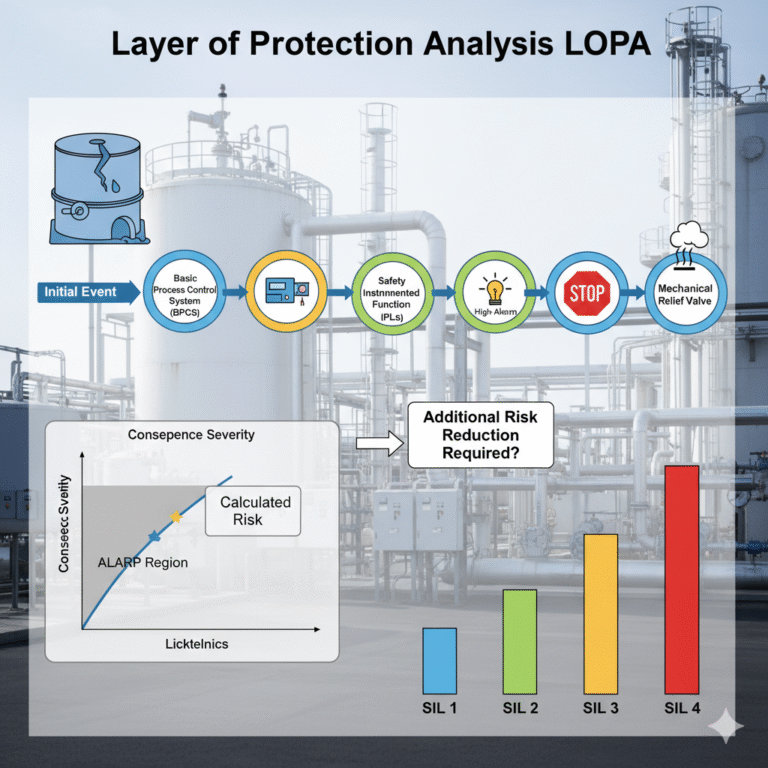

Layer of Protection Analysis (LOPA) is a semi-quantitative risk analysis technique that builds on qualitative hazard analysis. It evaluates specific accident scenarios to determine if the risk level complies with acceptable risk standards. LOPA helps identify whether additional risk reduction measures are required and, if necessary, determines the appropriate SIL for a SIF.

LOPA focuses on individual accident scenarios, utilizing predefined values such as initial event frequency, failure probabilities of Independent Protection Layers (IPLs), and consequence severity. The analysis compares the calculated risk to predefined risk standards to decide whether further risk mitigation is needed.

LOPA Methodology

LOPA is based on qualitative hazard analysis, such as HAZOP (Hazard and Operability Study), What-if, or FMEA (Failure Mode and Effect Analysis). These methods identify potential hazardous scenarios. LOPA then quantifies the risk of each scenario to determine whether additional risk reduction is required.

The LOPA process involves several steps:

Scenario Identification: Risk scenarios are derived from qualitative hazard analyses or other sources, such as design assessments or incident investigations.

Consequence Analysis: Each scenario’s potential outcomes, including the severity and frequency of consequences, are assessed.

Risk Evaluation: The risk is quantified and compared with acceptable risk standards to determine whether additional mitigation is necessary.

Key Concepts in LOPA

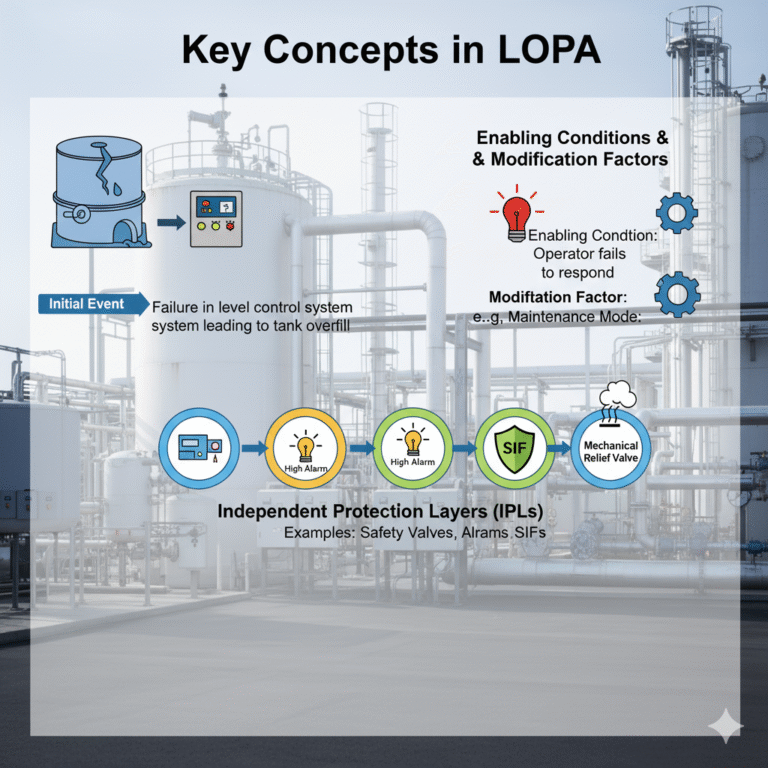

Initial Event: The first failure in an event chain that leads to a hazardous situation. For example, a failure in a level control system leading to overfill in a tank.

Independent Protection Layer (IPL): A layer that independently mitigates risk. Examples include safety valves, alarms, and SIFs.

Enabling Conditions and Modification Factors: Enabling conditions are necessary but not sufficient conditions for a scenario to develop, while modification factors adjust risk values based on operational conditions, such as equipment maintenance or environmental factors.

Risk Analysis and Tolerable Risk Standards

LOPA evaluates whether the consequences of an event exceed acceptable risk levels. The risk is composed of two parts: the likelihood of an event occurring and the severity of its consequences. Different industries and regions have varying standards for acceptable risk levels, often defined as the ALARP (As Low As Reasonably Practicable) risk region.

Once the consequences and frequency of an event are determined, the risk is assessed against predefined standards to evaluate if additional safety measures are required.

Determining SIL Requirements

If the risk of a scenario exceeds acceptable levels, a Safety Instrumented Function (SIF) may be required. LOPA can determine the appropriate SIL for the SIF by comparing the residual risk with acceptable risk levels.

SIL levels are categorized as follows:

SIL1: Low risk reduction.

SIL2: Moderate risk reduction.

SIL3: High-risk reduction, critical for safety.

SIL requirements must comply with international and national standards such as GB50770-2013 and GB/T21109-2007, ensuring the safety integrity of the system over its lifecycle.

Challenges and Considerations in SIL Determination

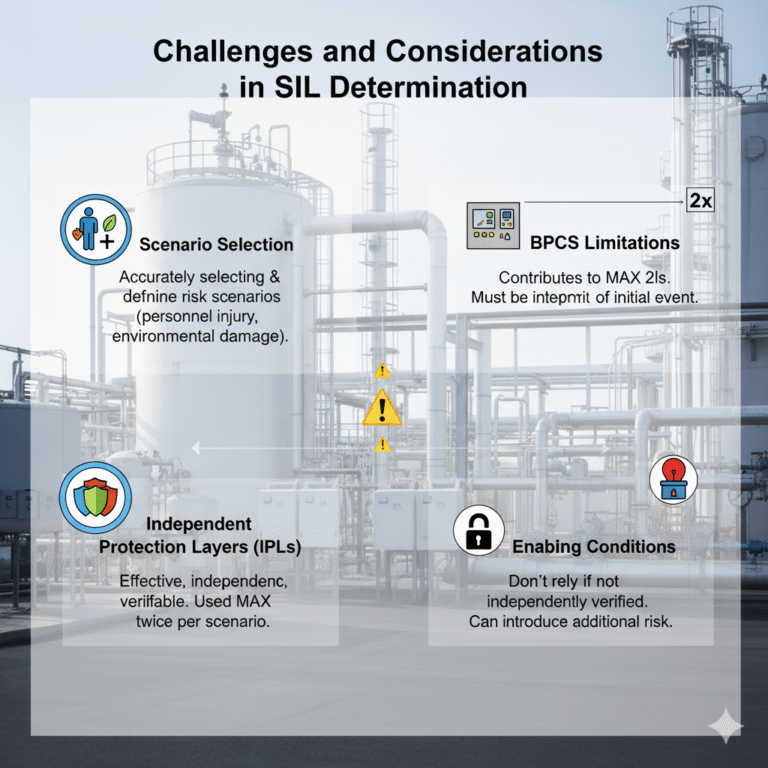

When implementing SIL determination in real-world projects, several important considerations must be kept in mind:

Scenario Selection: Accurately selecting and defining risk scenarios based on potential consequences (e.g., personnel injury, environmental damage).

Independent Protection Layers (IPL): Each IPL must be effective, independent, and verifiable. It cannot be used more than twice for a single accident scenario.

BPCS Limitations: A Basic Process Control System (BPCS) can only contribute to two independent protection layers, and it must remain independent of the initial event.

Enabling Conditions: Enabling conditions should not be relied upon if they can’t be independently verified, as they may introduce additional risk factors.

Conclusion

In the petrochemical industry and similar sectors, LOPA is a highly effective method for determining the required SIL for SIFs. By following the LOPA methodology and considering industry standards, engineers can ensure that their SIS meets the necessary safety requirements. This approach provides a systematic and structured framework for quantifying risk and implementing effective risk-reducing measures.