Control system design is often guided by specific process requirements. Based on these requirements, necessary measuring instruments and actuators can be added. However, the design process can vary significantly depending on the current system setup and any changes in the operational environment. The three key scenarios in control system design are:

Complete Control System Design from Scratch

In some cases, process design is clear and well-defined, with no existing control system. This scenario requires a fully open control system design, where all instruments, actuators, and control strategies are determined as part of the design phase.Improvement of an Existing Control System

This situation occurs when a control system is already in place and functioning well, but the process conditions change. The existing control system needs to be modified or optimized to accommodate new conditions. While this approach is less challenging than starting from scratch, it often involves significant constraints due to the limitations of the original design.Redesigning a Faulty Control System

The most complex and challenging scenario occurs when the existing control system design is flawed. In this case, a completely new control solution must be developed to address the underlying issues. Redesigning a control system often means starting from the ground up, as previous assumptions and strategies may no longer meet the process requirements.

Challenges in Control System Design

The first scenario—designing a completely new control system—is often the most difficult. This is because the design process frequently focuses on control implementation. However, many issues only become apparent during actual production. As a result, ongoing improvements are necessary, and the impact of any changes on the existing control system must be carefully considered.

Generally, when improving an existing control system, it is advisable to minimize changes to the original design. Significant alterations may introduce new problems, and without a thorough understanding of the system’s underlying principles, these improvements may fail to meet the required standards.

Key Principles for Evaluating Control Systems

One crucial aspect of evaluating a control system is determining whether it can operate without manual intervention during abnormal conditions. If a control system is overly complex or requires operator input to resolve issues, it is likely not an ideal solution. A well-designed control system should be simple and capable of handling unexpected situations autonomously.

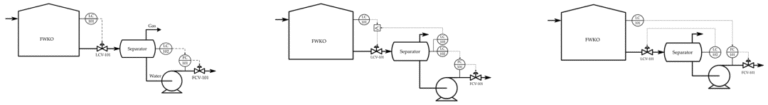

In the book Process Control: Engineering Analysis and Best Practices, a case study is presented that illustrates this principle. The leftmost diagram shows a simple single-loop control system with a built-in interlock to address abnormal situations. The middle diagram represents an overly complex improvement, while the rightmost diagram is the most efficient, employing a straightforward approach that resolves the problem in a simple and effective manner.

Conclusion

Designing an effective control system requires careful consideration of the specific process needs, current system limitations, and the potential for future improvements. The best approach is to keep systems simple, intuitive, and capable of functioning independently, ensuring long-term reliability and ease of use.