In the powder chemical industry, combustible dust explosions are rare but highly destructive “black swan” events. According to Dust Safety Science, between 2016 and 2020, the United States averaged approximately 31.8 dust explosions per year (excluding dust fires), resulting in numerous injuries and significant economic losses annually.

I. A Massive Explosion Triggered by a Small Clamp

A plastic factory used pneumatic vacuum conveyors to deliver polyethylene powder to an extruder. After routine maintenance, a clamp was misaligned, leading to a grounding failure. The high-speed flowing powder accumulated static electricity, which caused a spark and an explosion—this was a classic case of “oversight in the details.”

Lesson learned: Static discharge is one of the most overlooked ignition sources, often resulting from minor issues like grounding continuity failure, non-conductive hoses, or loose fittings.

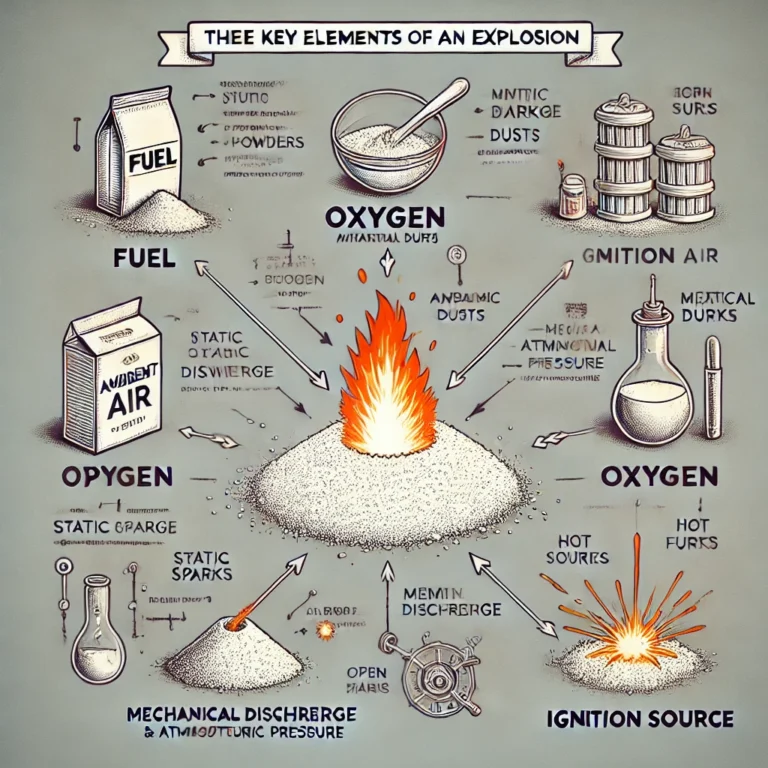

II. The Three Key Elements of an Explosion

Fuel:

Almost all organic dust (e.g., flour, sugar, grain dust) and many metal powders (e.g., aluminum, magnesium) can combust or explode under certain conditions.Oxygen:

Present in ambient air, with its levels influenced by humidity and atmospheric pressure.Ignition Source:

Common sources include static discharge, mechanical sparks (e.g., loose metal parts rubbing), open flames, and hot surfaces.

These three elements must all be present for an explosion to occur, and the most “designable” factor is often the ignition source, particularly static electricity.

III. Identifying Explosion Hazards

When designing explosion-proof systems, don’t just focus on the Minimum Ignition Energy (MIE). Pay attention to the following four parameters:

MIE (Minimum Ignition Energy):

Measured in millijoules (mJ), the lower the value, the more sensitive the material is. For example, sugar powder has an MIE of around 30 mJ, polyethylene powder ranges from 10-30 mJ, and some carbon or ink powders can go as low as 1-3 mJ.Kst & Pmax (Explosion Severity Index):

Kst: Maximum rate of pressure rise (bar·m/s), which determines the severity of the explosion.

Pmax: Maximum explosion pressure (bar g).

Classifications based on Kst:ST1 (0-200)

ST2 (200-300)

ST3 (300+).

For instance, sugar and flour are usually classified as ST1, wood dust can be ST2, and aluminum dust could be ST3.

MEC (Minimum Explosible Concentration):

The lowest dust concentration (g/m³) at which an explosion can occur, which is closely related to ventilation, dust removal, and dust collector design.MIT (Minimum Ignition Temperature):

Relevant for both gas clouds and dust layers, this helps manage temperatures of hot surfaces (e.g., ovens, dryers, abnormal bearing heating).

These parameters should be tested by accredited laboratories according to standard methods (such as the 20L sphere or 1m³ vessel), and re-tested when raw materials, particle size, humidity, or suppliers change.

IV. “Post-Explosion” Measures Aren’t Enough

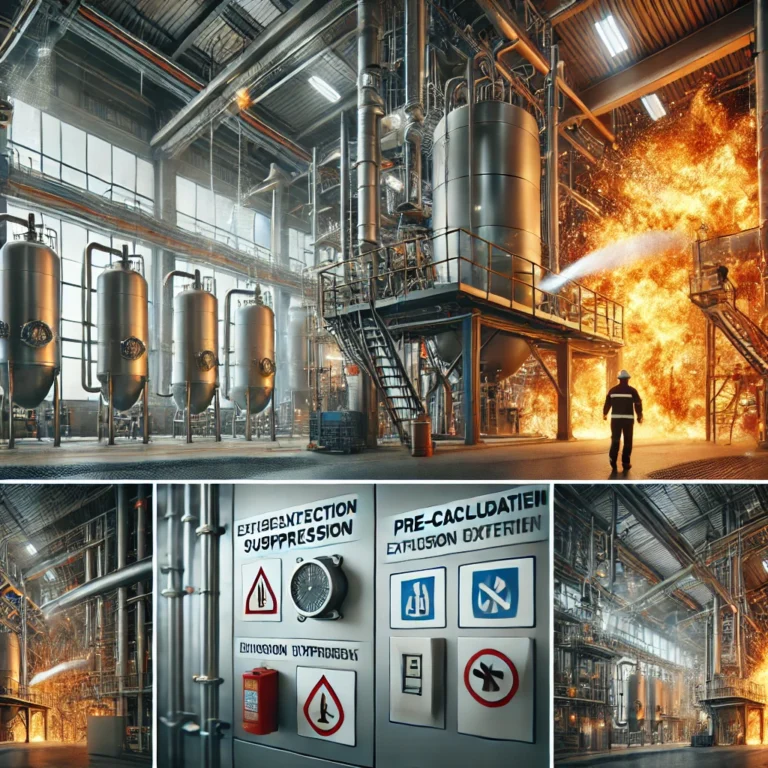

Traditional explosion protection methods (suppression, venting, and isolation) include:

Explosion Suppression:

Detecting flames and injecting chemical suppressants (e.g., sodium bicarbonate powders) to extinguish the fire quickly.Explosion Venting/Deflagration Venting:

Using pre-calculated venting ports to redirect the explosion energy safely.Explosion Isolation:

Preventing explosion propagation along pipelines through isolation valves or quick shut-off valves.

While these methods are important, their core flaw is that an explosion has already occurred, causing downtime, maintenance, and production losses.

V. Eliminate Ignition Sources from the Design

Pneumatic Vacuum Conveyors to Avoid Built-in Ignition Sources:

Take Volkmann’s pneumatic vacuum conveyor as an example: The system uses compressed air to drive multiple ejector vacuum pumps, creating negative pressure without motors, rotating parts, or significant heat sources. The entire system is designed to be conductive and certified for ATEX Zone 1/2/21/22. This type of sealed, dust-tight conveying system reduces dust leakage and secondary risks.Note: The equipment itself does not generate heat or electricity, but external utilities (e.g., compressed air) may still require electrical input. This reflects a proper understanding of “no electricity, no heat, no rotation.”

Static Electricity Management is a “Hard Requirement”:

Grounding/Continuity: According to NFPA 77 and IEC/TS 60079-32-1, a resistance of ≤1 MΩ is generally sufficient to dissipate static. Full metallic grounding circuits typically achieve <10 Ω.

Conductive Hoses/Filters: Choose static-conductive components with verifiable resistance and test them periodically.

Humidity Control: Low humidity increases the likelihood of static accumulation. Control moisture levels in processes and the environment when necessary.

Dust Hazard Analysis (DHA) for Process Management:

NFPA 652 requires facilities to conduct Dust Hazard Analysis (DHA), which identifies fire, flash fire, and explosion hazards, offering corrective measures and requiring a review every five years. This is especially crucial for multi-facility or multi-material processes.

VI. Engineering Implementation Checklist

Design/Selection Phase:

Obtain key material data: MIE, MEC, Kst, Pmax, and MIT (cloud & layer).

Prioritize using sealed, negative pressure, and conductive conveying systems (e.g., pneumatic vacuum).

Select electrical equipment according to ATEX/IECEx or NEC/CEC zoning (Zone or Class/Div), while meeting static electricity control requirements.

Include secondary protection (e.g., venting, explosion isolation) where necessary, based on Kst/Pmax.

Installation/Commissioning Phase:

Ensure proper grounding and continuity checks at all connection points, and perform traceable testing, including soft connections, clamps, and filters.

Conduct airtightness and leak point inspections to avoid “external air intake and dust re-suspension.”

Operational/Maintenance Phase:

Regularly review and update DHA.

Maintain cleanliness and dust collector management, ensuring dust layers do not exceed safe limits.

Periodically test grounding circuit resistance and document results.

Focus on critical “loose points,” such as clamps, for scheduled inspections.

VII. Prevent Explosions, Not Just Minimize Damage

Rather than investing in post-explosion damage control, focus on preventing explosions in the first place during the design phase:

Choose equipment with no electricity/low heat, continuous conductive systems for conveying and processing.

Use data-driven design, incorporating MIE, MEC, Kst, Pmax, and MIT, and make DHA an integral part of routine engineering management.