In the implementation of Distributed Control Systems (DCS) projects, three critical tests—Factory Acceptance Testing (FAT), Site Acceptance Testing (SAT), and Field Integration Testing (FIT)—play vital roles at different stages of the project. These tests ensure that the DCS system operates smoothly and meets the user’s needs. While each test is interrelated, they each focus on different aspects, together forming a comprehensive testing system.

Factory Acceptance Testing (FAT)

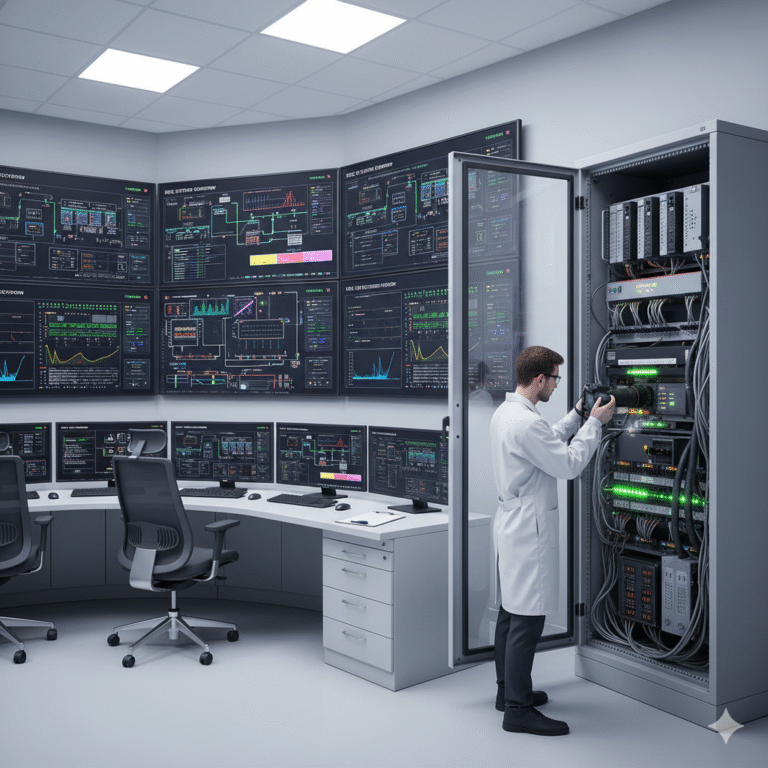

Factory Acceptance Testing (FAT) is conducted at the manufacturing facility. The primary goal of FAT is to verify that the DCS system’s hardware and software meet the technical and performance requirements outlined in the contract. This test is typically performed by the DCS manufacturer’s technical personnel, with the presence and confirmation of the owner and a third party. Only equipment that passes the FAT will be allowed to leave the factory. FAT involves a thorough inspection of both the hardware and software, as well as detailed validation of all components and programs to ensure compliance with the set standards and specifications.

Site Acceptance Testing (SAT)

Site Acceptance Testing (SAT) is performed once the equipment has been delivered to the final user’s site and installation is complete. The purpose of SAT is to verify the integrity of the DCS system and ensure that both hardware and software operate correctly in the actual on-site environment. This test also involves the manufacturer’s technical personnel and is usually taken over by the commissioning team after the verification process. During SAT, if configuration is done by the manufacturer, detailed testing of control functions and precise tuning of interlocks will be carried out.

Field Integration Testing (FIT)

Field Integration Testing (FIT) focuses on comprehensive testing of the DCS system in the field environment, with particular attention to the system’s ability to work in coordination with other systems. FIT ensures that the entire system runs efficiently and stably. Typically performed after SAT, FIT serves as the final quality check of the system’s integration, guaranteeing the system’s optimal performance and user experience.

Relevant Standards and Specifications

The following standard applies to FAT, SAT, and FIT processes for industrial automation systems:

GB/T 25928-2010 – Process Industry Automation Systems: Factory Acceptance Testing (FAT), Site Acceptance Testing (SAT), and Site Integration Testing (SIT) Specifications

This standard covers the following three stages:

FAT (Factory Acceptance Testing): Verifies system hardware and software functionality in the factory environment to ensure compliance with design specifications.

SAT (Site Acceptance Testing): Tests system functionality and performance at the user’s site to ensure compatibility with the actual operating environment.

SIT (Site Integration Testing): Conducted at the user’s site after system integration, to validate overall performance and stability.

The standard was officially implemented on May 1, 2011, and is managed by the China Machinery Industry Federation. Drafting organizations include the Shanghai Industrial Automation Instrumentation Research Institute, among others.

Note: These standards are applicable not only to DCS systems but also to PLC, SIS, GDS, CCS, and other control systems.