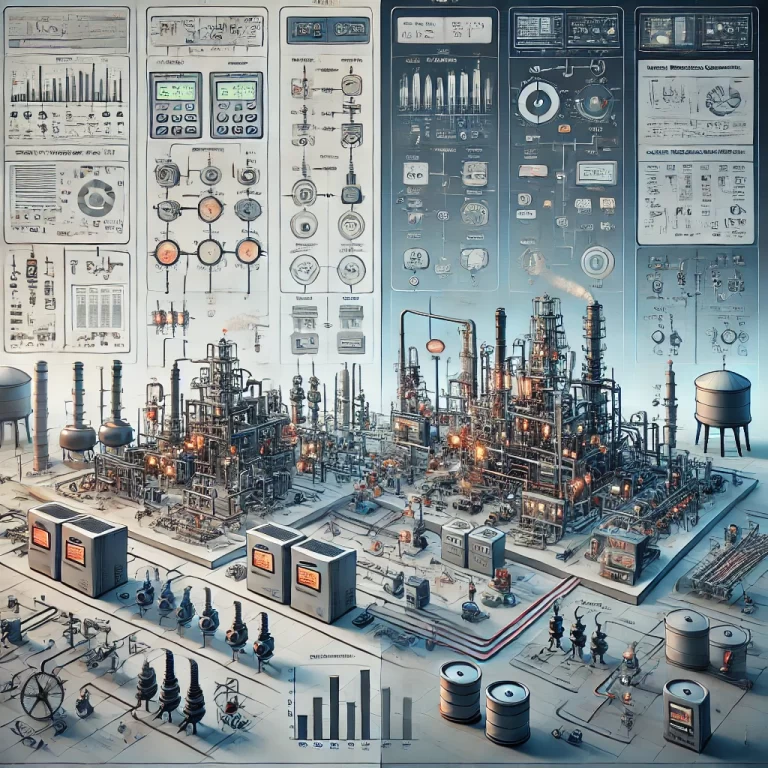

In the refining industry, there are tens of thousands of advanced control systems in operation, and when extended to sectors such as chemicals and power, the global number of such systems could reach hundreds of thousands. While offline mechanistic models exceed the scale of advanced control applications, real-time optimization based on steady-state mechanistic models is typically found in only a few thousand systems globally. However, both technical feasibility and economic considerations significantly limit the application of real-time optimization (RTO) in many plants.

Real-time optimization in the chemical industry is often referred to as the “crown jewel” of chemical digitization and smart manufacturing. Yet, despite its potential, many of these “gems” have become underutilized or neglected due to poor maintenance and limited operational scope. In some cases, they are barely functional, and the question arises: Is real-time optimization worth the investment?

Technical and Economic Feasibility

Real-time optimization, although promising in theory, faces substantial technical and economic barriers. One key challenge is the complexity of creating digital twins for real industrial processes. The level of modeling required can be as complicated as that used for aerospace simulations, making it a difficult and costly endeavor. In the case of ethylene cracking furnace optimization, for example, online analysis of raw materials and cracking gases, along with the construction of process models, involves significant costs. The integration of optimization platforms and advanced controls further increases engineering workload, making implementation a major challenge.

Once real-time optimization systems are delivered, maintaining stable, long-term, low-maintenance operation becomes a distant ideal. Regular maintenance, often seen as a new hurdle, is critical to system success. Any instrument malfunction, equipment failure, or process change can disrupt the system’s effectiveness, increasing the workload required to maintain optimal performance.

Is Real-Time Optimization Worth the Cost?

The cost of implementing and maintaining real-time optimization systems is high, and for many plants, the return on investment may not justify the expense. While there is undoubtedly a place for real-time optimization in certain applications, its broad applicability is questionable. For example, even in the case of ethylene cracking furnaces, the trade-off between optimization cost and benefit remains a point of debate.

For many facilities, a more reasonable approach could involve simpler optimization methods, such as offline modeling or periodic adjustments, rather than relying on complex, real-time systems. In the case of ethylene furnaces, for instance, controlling the cracking depth and optimizing furnace operations through planning could achieve most of the desired benefits without the heavy investment required for a real-time optimization system.

Conclusion

Real-time optimization is not always the most cost-effective solution for every industrial plant. While it can provide significant benefits in certain contexts, its complexity, cost, and maintenance demands make it unsuitable for widespread application. Industrial optimization is not solely about real-time systems—alternatives that consider the unique characteristics of each process can often provide more reliable, lower-cost solutions. In practice, quickly finding a satisfactory solution is often more important than striving for the perfect one.

In the future, industrial optimization efforts should focus on balancing technological advancements with practical considerations, ensuring that the solutions chosen offer the best value for each specific scenario.