General Safety Protocols

Strictly adhere to all safety regulations and operating procedures.

Properly wear and use personal protective equipment (PPE) such as helmets, safety shoes, and protective glasses.

Conduct a comprehensive risk assessment and hazard identification in the work environment.

Ensure that all equipment and tools are in good condition, and perform regular maintenance checks.

Clearly mark safety signs and warning labels in the field. Do not damage or ignore these warnings.

Maintain a clean and organized worksite. Remove debris and waste in a timely manner.

Specialized workers must hold relevant certificates to perform their duties.

Emergency and Unforeseen Situations

Stay calm and assess the situation swiftly. Activate the emergency response plan promptly.

Follow the designated evacuation route and exit the danger zone in an orderly manner to avoid panic and stampedes.

Issue an emergency alarm and notify the relevant personnel.

In case of a fire or similar emergency, use the appropriate firefighting equipment to perform initial fire suppression.

Provide basic first aid to injured personnel and arrange for their safe transfer, if necessary.

Follow the instructions of on-site supervisors and coordinators.

Report the incident to upper management accurately and promptly.

Secure the site to facilitate post-incident investigation and analysis.

Instrument-Specific Safety Guidelines

Secure Installation: Ensure that all instruments are securely installed to prevent accidents caused by loose instruments during operation.

Protection Level: Select instruments with the appropriate protection level based on the working environment to avoid damage from dust, moisture, or corrosive substances.

Proper Wiring: Follow the instrument’s manual and electrical regulations for wiring to avoid potential risks like short circuits or electric leaks.

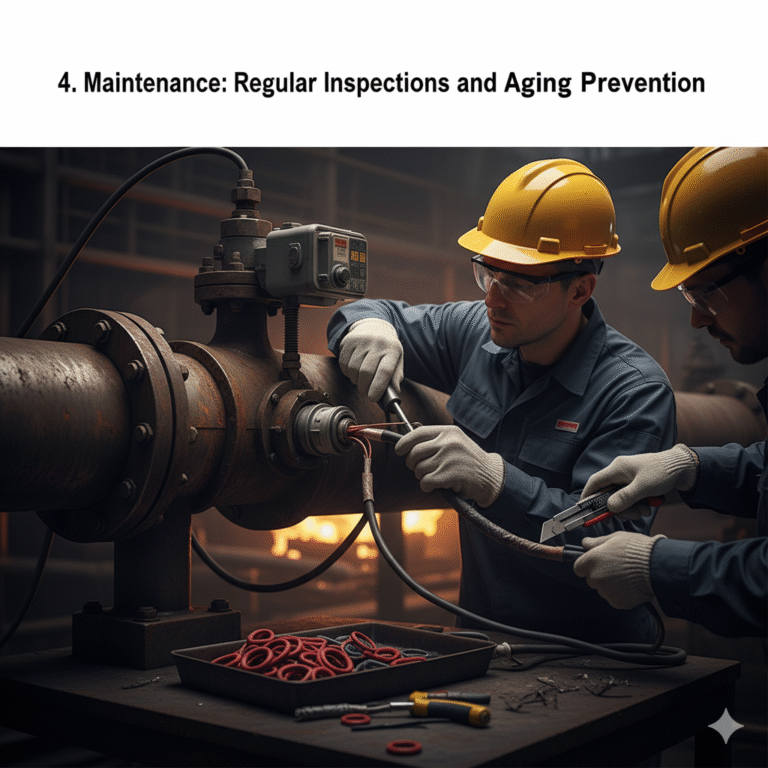

Regular Calibration: Perform routine calibration and maintenance to ensure the accuracy and reliability of instruments.

Clear Markings: Instruments should have clear markings indicating functions, ranges, units, etc., for easy operation and understanding.

Electrostatic Discharge Protection: Implement appropriate measures to eliminate electrostatic risks, particularly in environments prone to static build-up.

High/Low-Temperature Protection: For instruments working in extreme temperatures, ensure adequate heat insulation or protection to maintain safe operation.

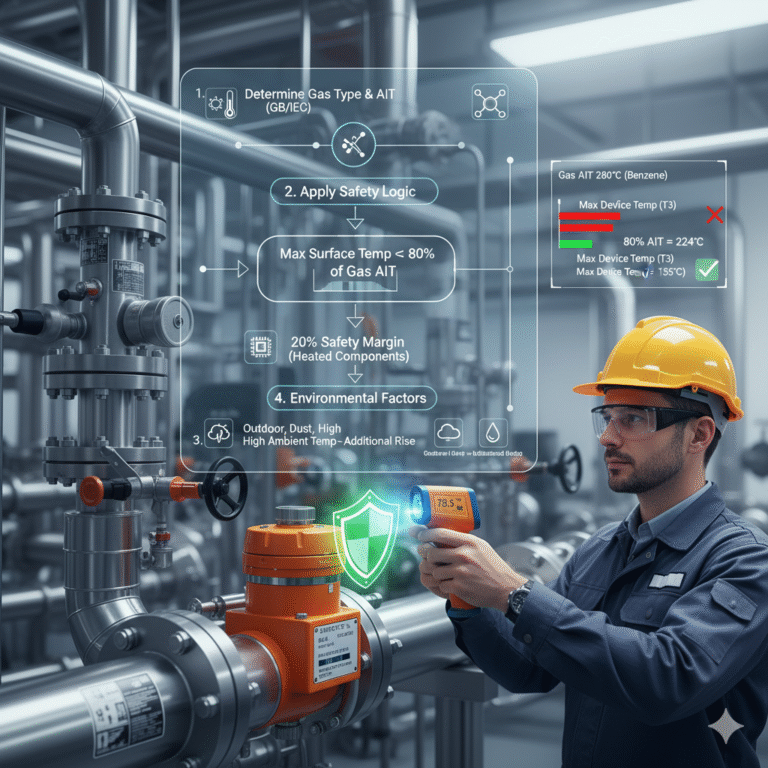

Explosion-Proof Instruments: In explosive environments, use explosion-proof instruments in compliance with safety standards.

Operator Training: Ensure that all operators are professionally trained and familiar with instrument operations and safety precautions.

Emergency Shutdown: Install emergency shutdown switches or devices to quickly stop the operation of instruments in case of anomalies.

Surrounding Environment Safety: Keep the area around instruments clean and free of obstacles that could hinder operation or maintenance.

Reliable Grounding: Ensure that instruments are properly grounded to protect personnel and guarantee proper function.

Additional Safety Considerations

Lightning Protection: In areas prone to lightning strikes, install effective lightning protection for instruments to avoid damage.

Interference Mitigation: Implement shielding and filtering techniques to minimize electromagnetic interference, ensuring accurate and stable readings.

Pressure Protection: Instruments subject to pressure should be capable of withstanding the specified pressure limits to prevent ruptures.

Toxic and Hazardous Gas Monitoring: Install gas detectors in locations with potential exposure to toxic or harmful gases, and regularly calibrate them.

Safety Interlocks: Connect critical instruments with other equipment to establish interlock mechanisms, ensuring safe system operation.

Fire Protection: Select instruments with appropriate fire-resistant properties according to fire safety standards.

Cleaning and Maintenance: Regularly clean instruments to prevent dust, debris, or other materials from affecting performance and to extend their lifespan.

Emergency Lighting: Ensure emergency lighting is available in areas where instruments are installed, enabling operation and maintenance during power outages.

Personal Protective Gear: Operators should wear the necessary protective gear, such as gloves and goggles, when handling instruments.

Data Security: For instruments with data storage or transmission functions, ensure that data is protected and remains confidential.

Maintenance Emergency Plan: Develop and follow a maintenance emergency plan that includes clear procedures and designated personnel.

Software Updates: Regularly update the software on instruments to fix vulnerabilities and enhance performance.

Environmental Suitability Assessment: Conduct thorough environmental suitability assessments before using instruments in specialized conditions.

Spare Parts Inventory: Maintain an inventory of essential spare parts to facilitate timely repairs and replacements.

Visual Inspections: Perform regular visual inspections to detect external damage, loose connections, or other potential issues with instruments.

Instrument Maintenance “Seven Approaches”

Assume Gas Presence When None Exists: Assume gas is present when performing maintenance in areas that typically contain gases and take necessary protective measures.

Assume Pressure When None Exists: Assume that pressure is present when working in areas where pressure is usually applied, and implement safety protocols.

Assume Toxicity When None Exists: Assume the presence of toxic substances in the work area and wear appropriate protective equipment to avoid health risks.

Assume Electricity When None Exists: Even if there is no electrical power, assume that power could be present and take steps to disconnect the power supply.

Assume Liquid Presence When None Exists: Assume that liquid may be present in systems even when not visible, and take steps to prevent spills or splashes.

Assume Corrosive Substances When None Exist: In corrosive environments, assume the presence of corrosive materials and use corrosion-resistant tools and materials.

Assume Danger When None Exists: Maintain awareness of potential hazards, even if they are not immediately visible, to ensure safe maintenance operations.

Instrument Maintenance “Ten Things Not to Repair”

No Approval for Maintenance: Do not proceed with maintenance unless it has been properly approved through the required procedures.

Unclear or Unapproved Materials and Equipment: Do not perform maintenance without clear specifications and certification for equipment and materials.

Equipment in Operation: Never perform maintenance on equipment that is still running; ensure all equipment is shut down before starting work.

Inadequate Pressure Relief: Do not perform maintenance on equipment that has not been fully depressurized.

No Power Shutdown: Do not proceed with maintenance on equipment unless power has been fully disconnected and properly secured.

Unverified Equipment: Never work on equipment that has not been formally handed over and properly verified.

Inadequate Isolation of Hazardous Materials: Do not perform maintenance without properly isolating hazardous substances, such as toxic, flammable, or corrosive materials.

Unclean Equipment Containing Hazardous Substances: Do not repair equipment that still contains hazardous substances unless it has been properly cleaned.

Working in Confined Spaces Without Monitoring: Do not enter confined spaces for maintenance without proper monitoring and authorized personnel.

Unsafe Maintenance Conditions: Do not conduct maintenance in environments that do not meet safety standards, such as poorly lit or poorly ventilated areas.

Instrument Work Practices

Power Shutdown Procedure:

Ensure a work order is obtained for the power shutdown.

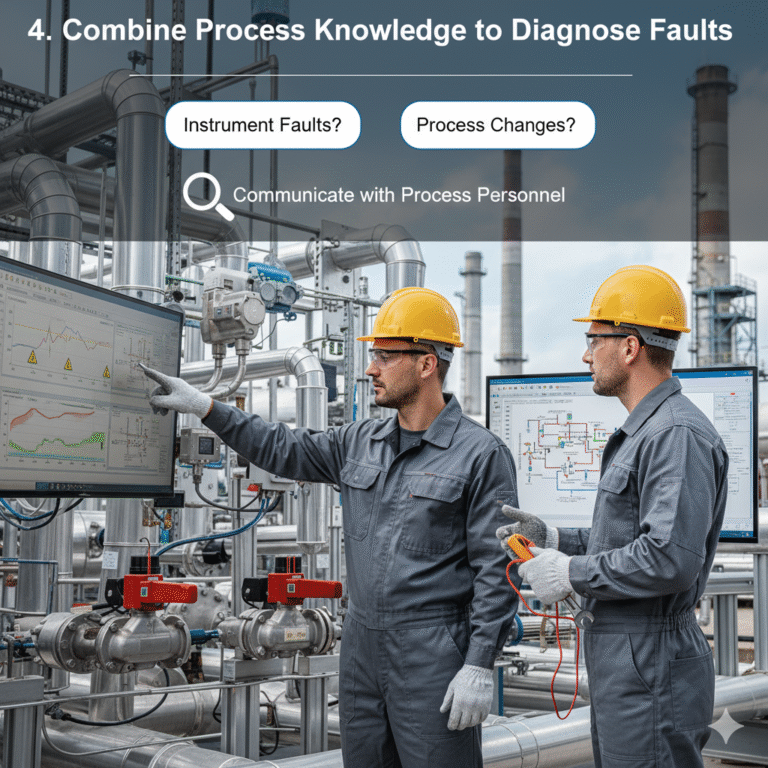

Perform a double confirmation of the shutdown equipment with a colleague.

Ensure that no other devices are connected to the same switch or breaker during the shutdown process.

Wiring and Disconnection:

Any operation that affects the process monitoring system must have proper work orders and double confirmations to prevent incorrect disconnections.

Ensure that the power is shut off before working on powered instruments.

Instrument Drainage:

Drainage operations should only be performed when necessary and with proper protective measures to prevent leaks or other hazards.

System Installation and Setup:

Install systems after obtaining proper authorization and following necessary risk assessments.

Ensure that all required measures and checks are in place before the installation begins.

Forced Measurement Points:

Apply proper documentation when implementing forced measurement points, ensuring that the system is not impacted.

Interlock Debugging:

Ensure that all system interlocks are properly tested and confirmed with both DCS and process personnel involved.

Gas Source Shutdown:

Follow proper procedures to ensure safe disconnection of gas sources, avoiding unwanted actions on multiple valves.

Interface Disconnection:

Disconnect interfaces only after proper depressurization to avoid media spillage or damage.