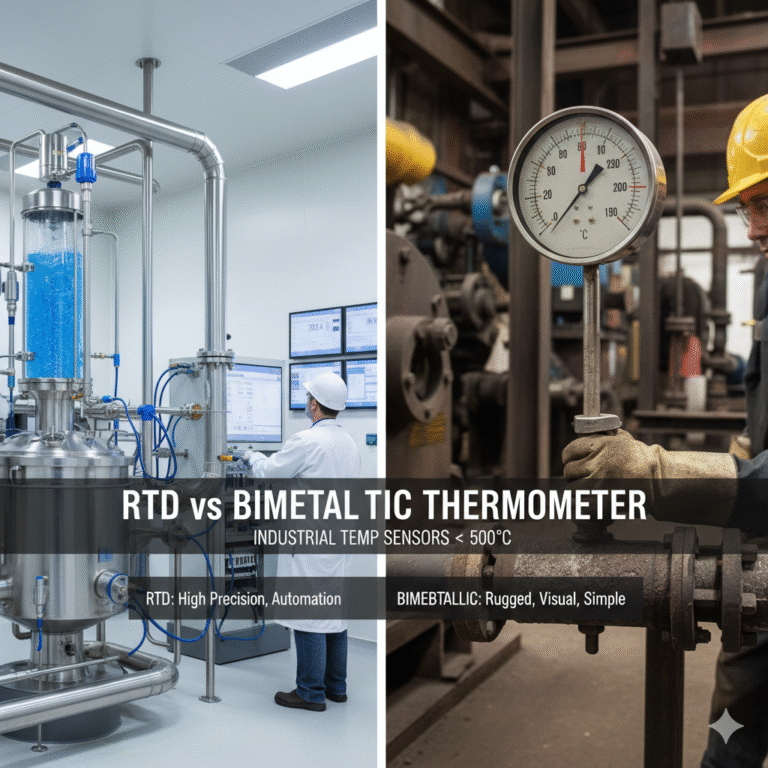

Temperature measurement plays a critical role in various industrial processes. Whether you are controlling a chemical reaction, monitoring food sterilization temperatures, or ensuring safety in heavy machinery, the choice of temperature sensor can greatly impact the accuracy, reliability, and efficiency of your operations. When it comes to industrial temperature measurement below 500°C, two commonly used sensors are Resistance Temperature Detectors (RTDs) and Bimetallic Thermometers. In this post, we’ll break down the ideal scenarios for using each of these instruments to help you make the best decision for your specific needs.

When to Choose Resistance Temperature Detectors (RTDs)

1. High Precision Temperature Measurement

If your application requires high precision, RTDs are often the best choice. RTDs provide accurate and stable measurements over a wide temperature range, making them ideal for critical processes such as:

Chemical reaction temperature control

Food processing and sterilization temperature monitoring

Pharmaceutical applications

The high accuracy and stability of RTDs are essential in ensuring that the temperature stays within precise limits, avoiding safety risks or product quality issues.

2. Remote Data Transmission and Automation Integration

For applications where temperature data needs to be transmitted over long distances or integrated into an automated control system, RTDs offer a distinct advantage. They can output signals such as:

4–20mA analog signals

Digital signals (e.g., Modbus, HART)

This makes them easy to integrate into PLC or DCS systems, enabling remote monitoring, control, and data logging.

3. Stable Long-Term Measurement in Fluctuating Environments

RTDs are excellent for applications where temperature fluctuations are frequent, and long-term stability is essential. Common examples include:

Cold storage (e.g., warehouses, freezers)

Climate-controlled chambers

The ability to provide reliable measurements over extended periods in changing environmental conditions is a key strength of RTDs.

When to Choose Bimetallic Thermometers

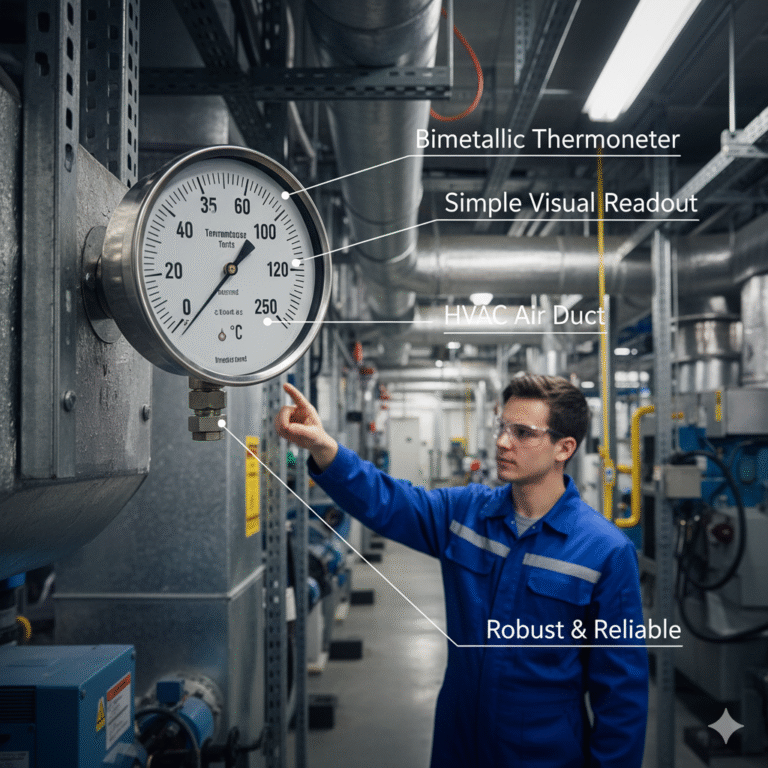

1. Simple Visual Readout with Lower Precision Requirements

In some applications, precise temperature control is not the primary concern, and all that is needed is a simple, visual temperature readout. Bimetallic thermometers are mechanical devices that use the deflection of a bimetallic strip to indicate temperature. They are commonly used in:

Air conditioning systems

Heating equipment

HVAC applications

In these cases, the primary requirement is a straightforward visual temperature indicator, with minimal precision needed.

2. Harsh Environments with High Vibration

Bimetallic thermometers are robust mechanical instruments that can withstand harsh conditions, such as:

Heavy vibrations

Extreme temperatures

Industrial environments

They are often used in places like kilns, furnaces, or boilers, where electronic devices like RTDs may be prone to failure due to vibrations, dust, or high temperatures. Their mechanical construction allows them to endure physical wear and tear that could damage more delicate sensors.

3. Cost-Effective Solutions with No Need for Complex Signal Processing

If you are operating within a tight budget and don’t require complex signal processing or remote integration, bimetallic thermometers are a cost-effective solution. They offer:

Low initial cost

No need for specialized equipment or signal conversion

This makes them a popular choice for non-critical applications where budget constraints are a concern.

Conclusion: Which Should You Choose?

In summary, both RTDs and bimetallic thermometers have their distinct advantages depending on the requirements of your application:

Choose RTDs when you need high precision, remote data transmission, and stable measurements in fluctuating environments.

Choose bimetallic thermometers when you need a simple, cost-effective solution for environments with high vibration or when precise temperature control is not a priority.

Understanding the specific demands of your industrial environment will guide you in selecting the right temperature sensor. Always ensure that the sensor you choose matches your operational needs to achieve the best performance and reliability in your processes.