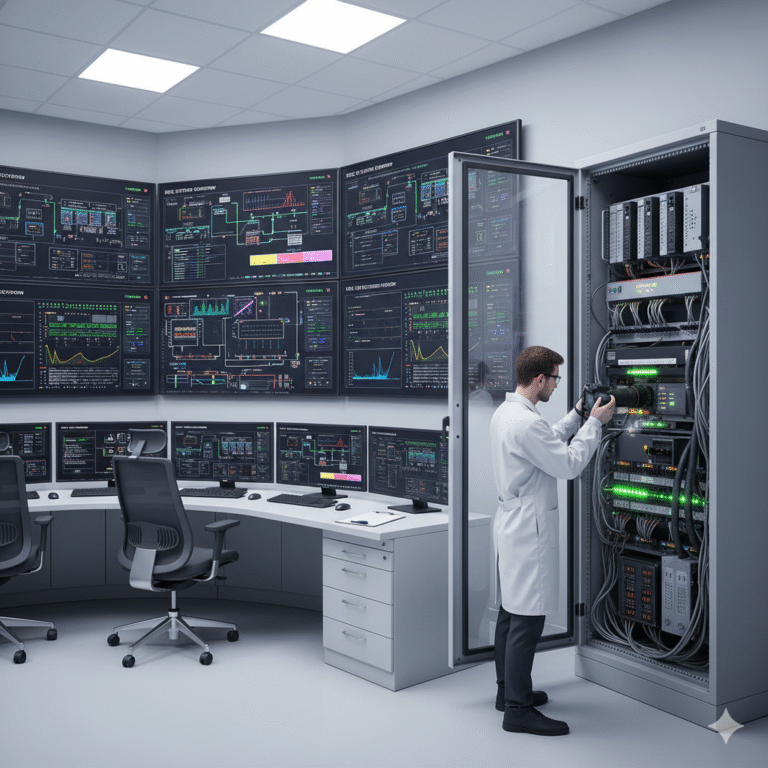

1. DCS System Inspection

Regular Inspections:

Conduct inspections twice a day at designated times.

Dust Removal:

Clean the control cabinet and operating desk exterior weekly.

Clean the interior components like computers, control stations, and fans every week. Replace the cabinet filters bi-weekly.

Inspect fans daily for proper operation and replace damaged units promptly.

Inspection Content:

Environmental Checks: The required operating environment for DCS systems includes:

Temperature: 15°C to 28°C

Vibration amplitude: <0.5mm

Humidity: 45% to 70%, non-condensing

Dust content should meet Level 2 standards.

Clean air helps prevent poor ventilation, dust accumulation on circuit boards, and racks, which can cause shorts or equipment damage. Regular inspections of the central air conditioning and its operation should be performed. If there are abnormal temperatures or humidity, they should be addressed immediately.

Daily Checks:

Visual Check: Inspect the status indicators of CPUs, I/O cards, and power modules to ensure they are in the correct position.

Auditory Check: Listen for abnormal noises from power supplies or cooling fans.

Touch Check: Feel the power units to ensure they are not overheating.

Also, review the system’s equipment status on the DCS screen to ensure that nodes and network states are functioning properly, with no system freezes. If any issues are found, corrective actions should be taken immediately.

System Security and Management:

Establish comprehensive management regulations for system maintenance, including control permissions, configuration modifications, software management, and system virus protection.

Enforce strict management of signal forcing, historical data retrieval, and important interlock operations, especially during plant operation, to avoid changes that could cause system failures.

Load and Performance Testing:

Regularly check the load on controllers and test CPU utilization. Under heavy load conditions, ensure the CPU usage does not exceed 60% for control stations and 40% for data management stations.

Inspect hardware like control cabinets, hosts, monitors, mice, keyboards, network devices, power cords, communication lines, and signal lines for integrity.

2. DCS System Maintenance

System Backups:

Software Backups: Regularly back up system software, operating systems, drivers, emergency boot disks (especially for WinNT systems), and control system software.

Project Software Backups: Ensure backups of both lower and upper-level engineering configuration software, control databases, and subdirectories. Ensure these files are up-to-date and complete.

Hardware Backups:

Backup essential and frequently worn-out components like keyboards, I/O modules, power supplies, communication cards, and fans, based on actual needs.

Service Documentation:

Maintain contact information for hardware manufacturers, system designers, and service personnel. Keep track of after-sales service coverage, schedules, and related documents.

Preventive Maintenance:

Proactively maintain the system by detecting and replacing faulty components to eliminate potential risks. Perform annual preventive maintenance during shutdown periods to assess the system’s operational state.

Backup Data Before Shutdown: Prior to any system shutdown, ensure backups of configuration software and data. Use blank disks and hard drive backups to secure data.

Card Cleaning and Dust Removal:

Clean internal components like the control station, power units, and card modules during downtime. Use special cleaning agents if dust remains after blowing out the dust. Proper static protection must be observed during this process.

Grounding System Maintenance:

Regularly inspect terminals and check the grounding resistance to meet regulatory standards (≤2Ω for independent grounding systems).

Hardware and Software Upgrades:

Periodically upgrade hardware and software to meet new requirements and resolve issues in older systems. Perform these upgrades during routine maintenance periods.

3. DCS System Fault Diagnosis and Handling

Fault Maintenance:

Upon system failure, fast and accurate fault diagnosis is essential. The following steps should be followed:

If fluctuating data does not impact the process, it may be a failure in a card or module. Switch related systems to manual and notify maintenance personnel for inspection.

Check the status of operation stations. If one station freezes, verify if the issue is isolated to that station or part of a larger network failure.

Investigate power supply issues if multiple stations lose display or functionality.

Common Fault Handling:

Operator Station Freeze: Causes can include incorrect operation, software crashes, or hardware issues like faulty fans or hard drives. To resolve, restart the station and reload the engineering files.

Process Channel Failures: Typically caused by I/O card malfunctions. These can be diagnosed using system diagnostics or by replacing the faulty card.

Signal Interference: Interference can disrupt analog signal accuracy, potentially affecting system stability. Ensure proper grounding and shielding of cables to avoid issues.

Power Failures: Even with redundant power supplies, faults in power circuits or UPS systems can cause DCS failures. Regular checks of the power systems are crucial to prevent interruptions.