In modern industrial automation, explosion protection is one of the most critical design requirements. Whether it’s in chemical plants, oil and gas platforms, pharmaceutical factories, or coal mining systems, any area with flammable gases or dust requires strict control over the propagation of electrical energy.

Among many explosion protection measures, one small device is often overlooked, yet it determines whether a system can operate “safely”—the Safety Barrier. Despite its compact size, it is the “final line of defense” in the entire intrinsic safety system.

What is a Safety Barrier?

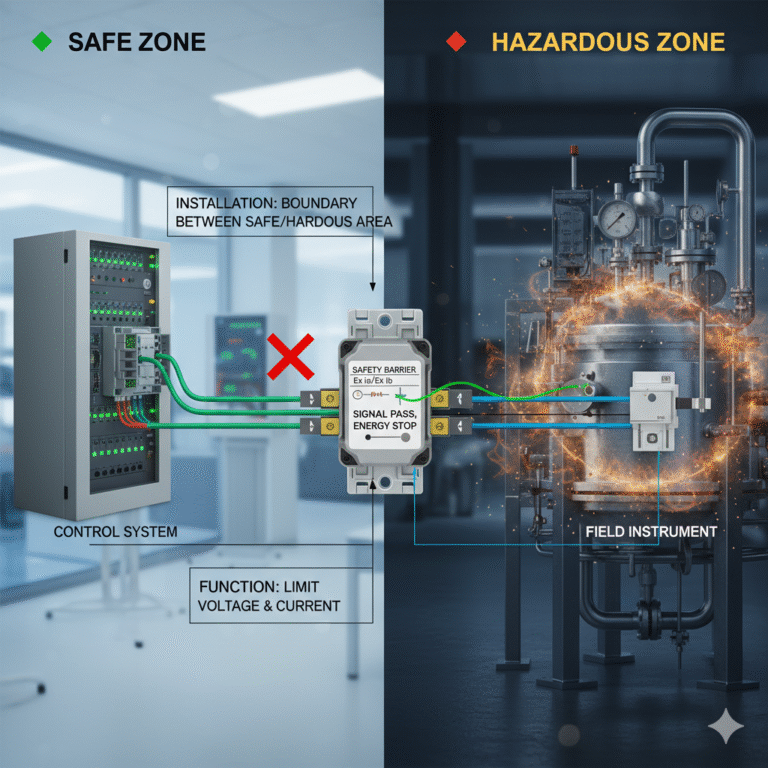

A safety barrier is a device designed to prevent hazardous energy from entering a hazardous area. It is typically installed at the boundary between a safe zone and a hazardous zone. One end connects to the control system, and the other to field instruments.

Its job is to “let the signal pass, but stop the dangerous energy.”

The safety barrier strictly limits the voltage and current entering the hazardous zone to ensure that, even in the event of a system failure, sparks or heat will not be generated that could ignite flammable gases.

Types of Safety Barriers

Safety barriers are generally divided into two categories based on their operating principles:

Zener Safety Barriers:

These rely on Zener diodes, resistors, and fuses to provide over-voltage and over-current protection.Isolated Safety Barriers (Isolation Barriers):

These offer additional isolation using optical, electromagnetic, or transformer coupling to completely separate signals and energy.

Zener Safety Barriers

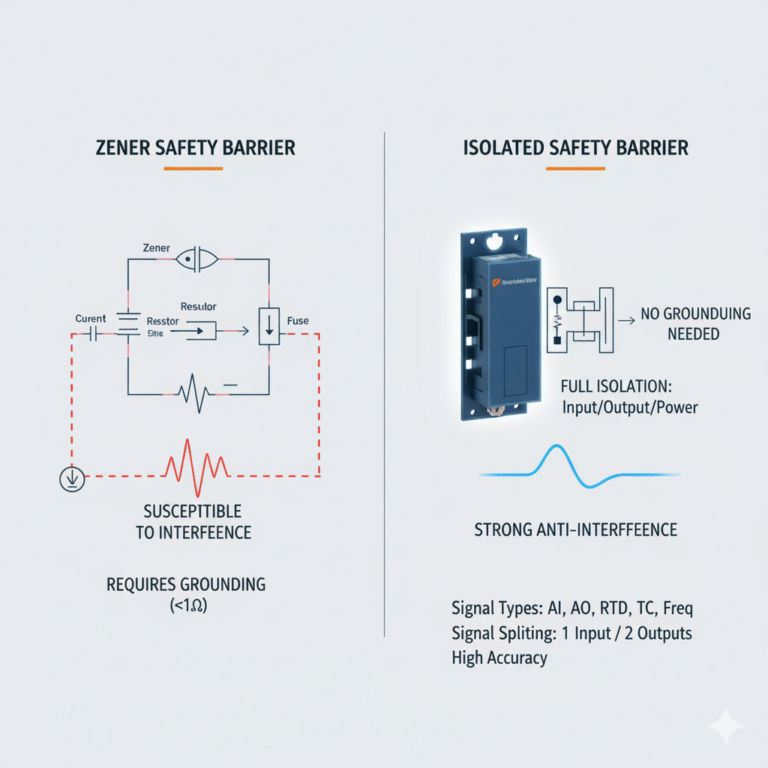

The Zener safety barrier is the simplest and earliest type. Its principle can be summarized as “three levels of protection”:

Zener diode voltage limitation: When the voltage exceeds a preset value, the Zener diode conducts and clamps the voltage within a safe range.

Series resistor current limitation: Controls the current passing through the hazardous zone.

Fuse protection: Quickly cuts the circuit in the event of a severe fault, preventing energy from continuing to pass through.

The main advantage of Zener barriers is their simple structure, low cost, and fast response. However, it’s essential that the system is properly grounded; otherwise, the barrier’s voltage-limiting function will be ineffective, reducing explosion-proof performance.

Isolated Safety Barriers

As industrial systems became more complex, the need for signal reliability and anti-interference grew. Isolated safety barriers were developed to meet this demand.

These barriers not only provide voltage and current limiting but also achieve full isolation of input, output, and power supply. This isolation resolves issues like ground loop interference and signal crosstalk.

Key advantages include:

No need for grounding, allowing more flexible installation

Strong anti-interference performance, leading to more stable signals

Capable of handling various signal types such as current, voltage, frequency, thermocouples, and RTDs

Supports signal splitting for two outputs

High accuracy and long-term stability

As a result, isolated barriers have become essential in modern PLC and DCS systems for signal protection.

What is the NAMUR Standard?

If safety barriers act as the “hardware guardians” of explosion-proof systems, then NAMUR is the organization that sets the “language rules” for these systems worldwide.

NAMUR Overview

NAMUR (the Association for Standardization in the Chemical Industry), founded in 1949 in Germany, is one of the most influential user organizations in the industrial automation field. It specializes in setting guidelines for automation applications, especially in the chemical and process industries.

Although NAMUR doesn’t issue legally binding standards, its recommendations (NE series) have become crucial references in international and domestic explosion-proof standards such as IEC and EN.

NAMUR and Safety Barriers: A Perfect Collaboration

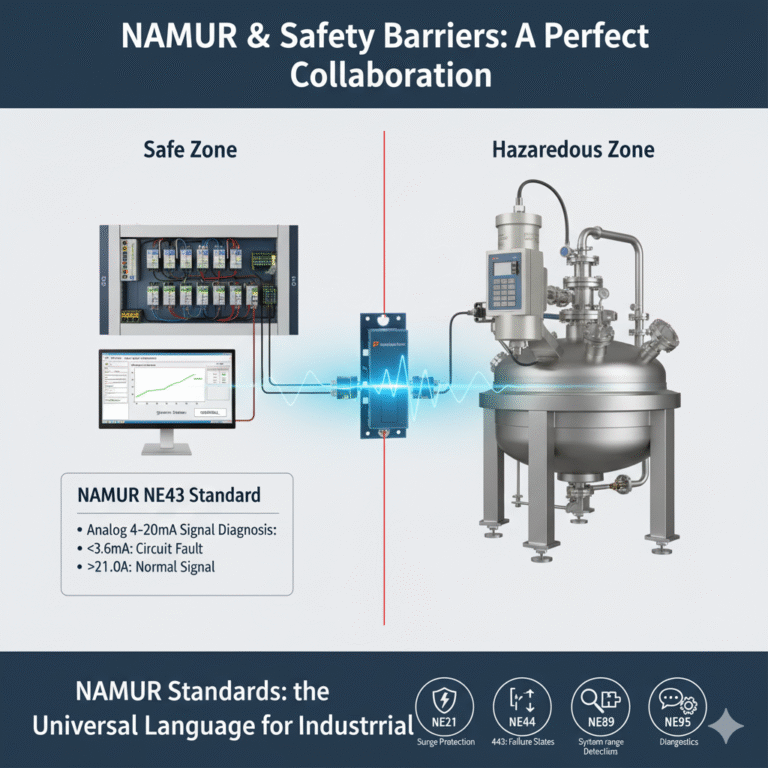

NAMUR has developed key standards regarding field signals, explosion-proof interfaces, and system interoperability. Some of the critical ones related to safety barriers include:

NE21: Specifies signal interference and surge protection requirements

NE43: Defines failure states for analog signals (4-20mA)

NE44: Specifies methods for detecting open or short circuits

NE89: Provides guidelines for selecting and matching intrinsic safety systems

NE95: Specifies diagnostic and communication interface requirements

These standards ensure that safety barriers, transmitters, and control systems from different manufacturers can work together seamlessly. For example, according to NE43, a control system can detect the status of instruments through signal currents:

<3.6mA → Circuit fault or instrument failure

>21.0mA → Over-range

4–20mA → Normal signal

Thus, NAMUR standards have become the universal language for signal diagnostics in global DCS/PLC systems.

NAMUR Sensors and Safety Barriers

NAMUR doesn’t only specify the performance requirements for safety barriers but also defines the output characteristics of NAMUR two-wire sensors. These sensors output very low current (typically around 1mA) and must be paired with safety barriers to ensure reliable signal transmission.

| Signal Type | NAMUR Definition | Safety Barrier Role |

|---|---|---|

| Two-wire switch | Open: <1.2mA; Closed: >2.1mA | Amplify signal and limit energy |

| Analog 4-20mA | Failure: <3.6mA or >21mA | Signal diagnosis and alarm |

| Digital/Frequency signals | Complies with NE21 interference immunity requirements | Enhanced surge protection |

As a result, in modern chemical, pharmaceutical, and petrochemical industries, NAMUR sensors paired with safety barriers have become the standard for ensuring intrinsically safe signal chains.

Proper Selection and Installation of Safety Barriers

Correct selection is the first step to ensuring system safety and reliability. Key considerations include:

Clearly define signal type (AI, AO, DI, DO)

Verify explosion protection ratings (Exia/Exib)

Match intrinsic safety parameters (Uo≤Ui, Io≤Ii, Po≤Pi)

Choose products certified by NAMUR NE21/NE43

Ensure installation requirements and channel counts match system needs

For installation:

Zener barriers must be well-grounded (ground resistance ≤1Ω)

Isolation barriers should be kept well-ventilated and spaced to avoid overheating

Separate signal and power lines in cable trays

Clearly label terminals distinguishing safe and hazardous areas

Verify signal polarity and wiring before commissioning

Application Examples

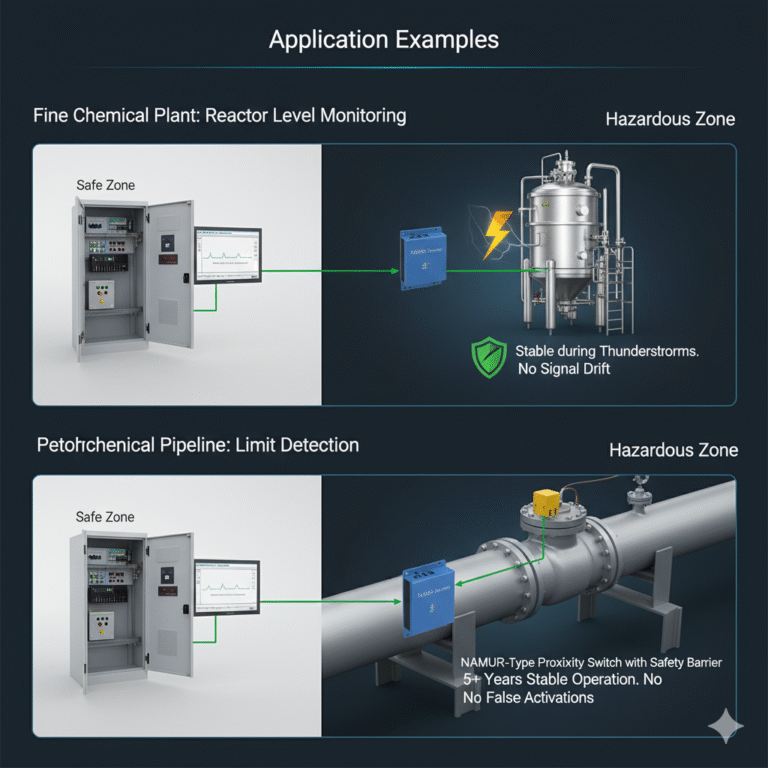

In a fine chemical plant’s reactor level monitoring system, engineers selected an isolated safety barrier with a NAMUR NE43-compliant level transmitter. The system achieved high-precision temperature monitoring and maintained stable operation even during thunderstorms, with no signal drift or false alarms.

In another petrochemical pipeline monitoring project, NAMUR-type proximity switches used with safety barriers ensured remote limit detection. The signal transmission remained stable for over five years without any false activations.

While seemingly small, safety barriers play a crucial role in maintaining the safety of entire systems at critical moments.

Conclusion

Safety barriers act as silent guardians—while they don’t participate in control, they protect every signal’s safety. They don’t emit energy, but ensure that energy in hazardous zones is tightly controlled. The integration of NAMUR standards brings a more systematic approach, creating a shared language for engineers and allowing them to design secure signal chains in a more scientific and unified way.

Through the collaboration between safety barriers and NAMUR, the industrial systems that operate efficiently also maintain their intrinsic safety on the critical 4-20mA signal lines.