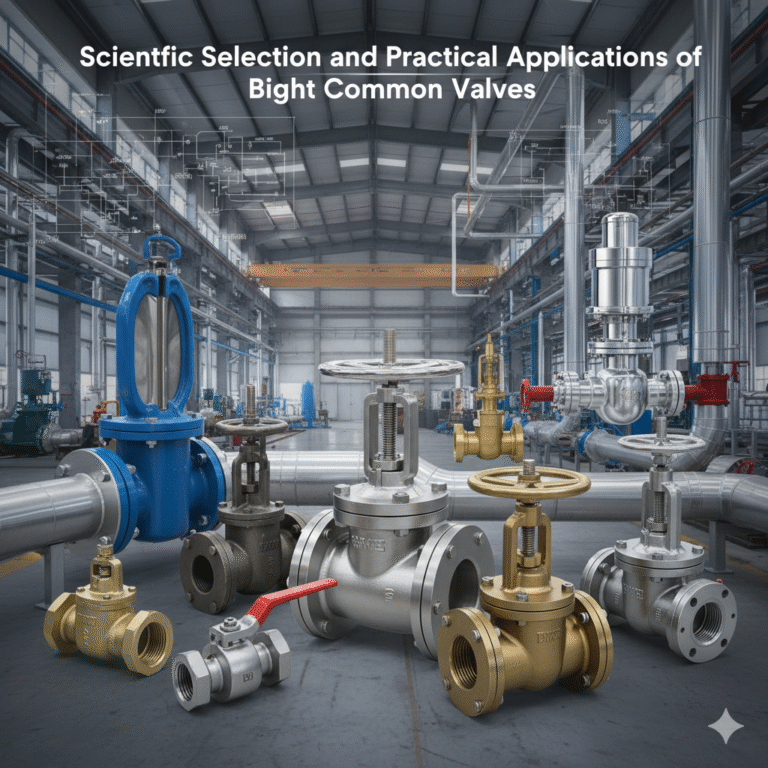

In modern industrial pipeline systems, valves play a crucial role in controlling the flow, pressure, and direction of fluids. They are widely used in industries such as petrochemicals, power generation, metallurgy, water treatment, pharmaceuticals, and energy. Different types of valves offer unique advantages in terms of structural design, sealing performance, and operational characteristics.

Understanding the features and application scenarios of common valves such as gate valves, globe valves, butterfly valves, ball valves, plug valves, check valves, safety valves, control valves, and mixing valves not only helps in selecting the right valve for the system but also improves safety, efficiency, and provides technical guidance for future maintenance and energy saving.

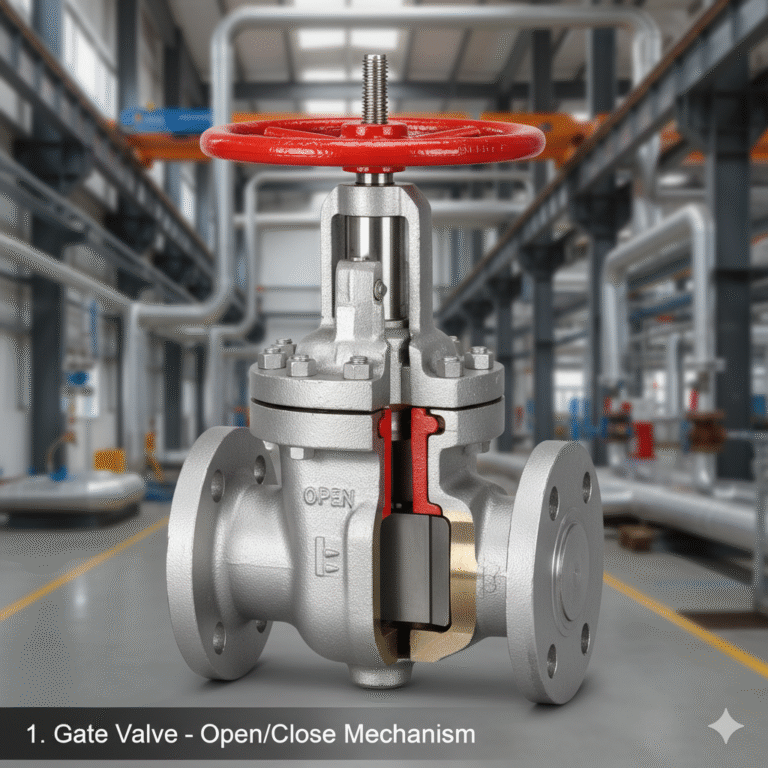

1. Gate Valve

Definition and Structure

A gate valve features a gate that moves up and down to open or close the fluid passage. It typically consists of a valve body, valve cover, gate, valve stem, handwheel, and sealing rings.

Advantages

Minimal fluid resistance when fully open, offering low pressure loss.

Requires less torque to open and close, making it easier to operate.

Simple structure, cost-effective manufacturing, and compact design make it easy to install.

Can be used in bidirectional flow systems.

Durable sealing surfaces that are less prone to erosion compared to some globe valves.

Disadvantages

Large size and high opening height require significant installation space.

The sealing surface undergoes sliding friction during operation, leading to wear, especially in high-temperature environments.

Long opening and closing times make it unsuitable for applications that require quick operation.

Application Scenarios and Selection Tips

Suitable for systems that remain fully open or fully closed for long periods, such as water and wastewater pipelines or large-diameter transport lines. Careful consideration should be given to the medium’s solid content, required installation space, and flow direction when selecting.

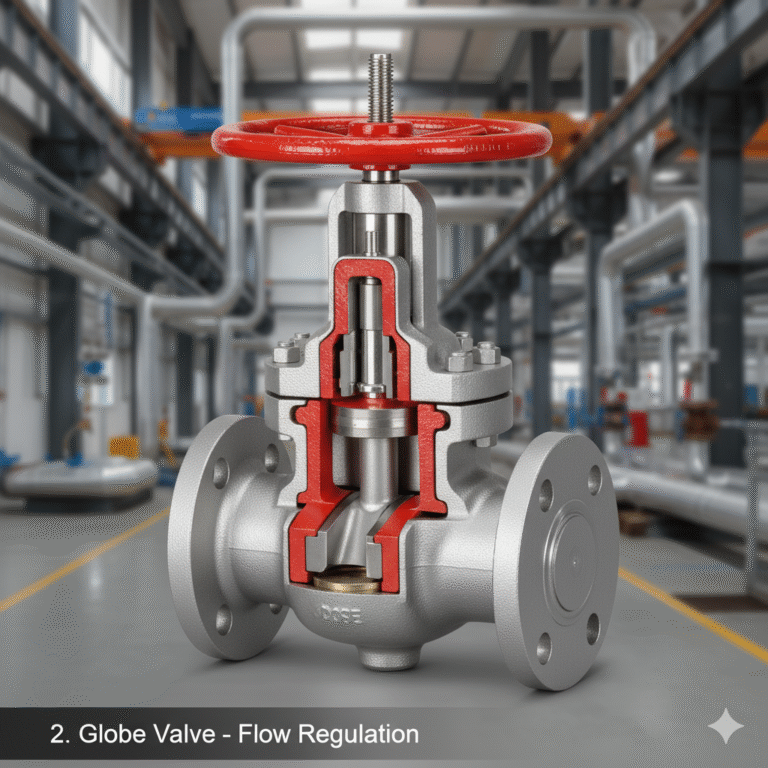

2. Globe Valve

Definition and Structure

A globe valve has a valve disc that moves along the centerline of the seat. Its opening is proportional to the stroke of the disc, making it ideal for regulating flow.

Advantages

Lower friction between the disc and seat compared to gate valves, leading to better wear resistance.

Smaller opening height compared to gate valves, making it suitable for applications with limited installation space.

Easier maintenance due to the fewer number of sealing surfaces.

Disadvantages

Higher pressure loss due to the change in flow direction through the valve body.

Slower opening speeds compared to ball valves.

While suitable for flow regulation, it has relatively high pressure loss.

Application Scenarios and Selection Tips

Ideal for systems that require good flow regulation or frequent opening and closing, such as steam systems, chemical processes, and pharmaceutical manufacturing. When selecting, consider the need for precise control over flow, pressure, and temperature.

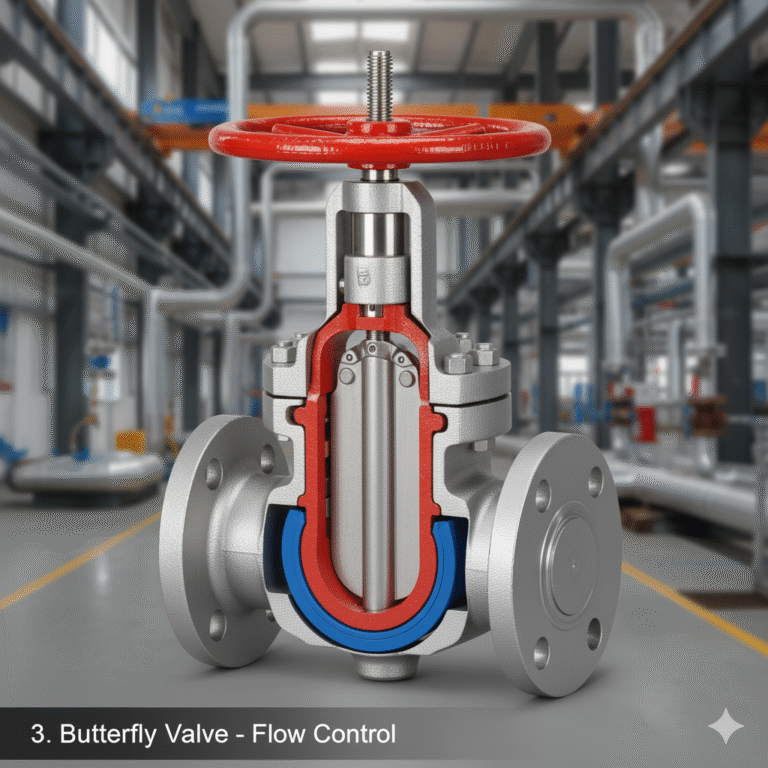

3. Butterfly Valve

Definition and Structure

The butterfly valve features a rotating disc that opens or closes the fluid passage by rotating approximately 90°.

Advantages

Simple structure, compact design, and lightweight, making it ideal for large-diameter valves.

Fast operation and low fluid resistance when designed correctly.

Can handle media with suspended solids, especially when made with corrosion-resistant materials like stainless steel or rubber.

Disadvantages

Limited flow control range: flow may be near full capacity when the valve is only 30% open.

Not suitable for high-temperature or high-pressure systems.

Sealing performance is generally not as high as that of ball or globe valves.

Application Scenarios and Selection Tips

Best suited for large-diameter, low-pressure systems like water treatment, heating, air conditioning, and wastewater pipelines. Consider the medium’s properties (e.g., suspended solids), temperature, and pressure range when selecting.

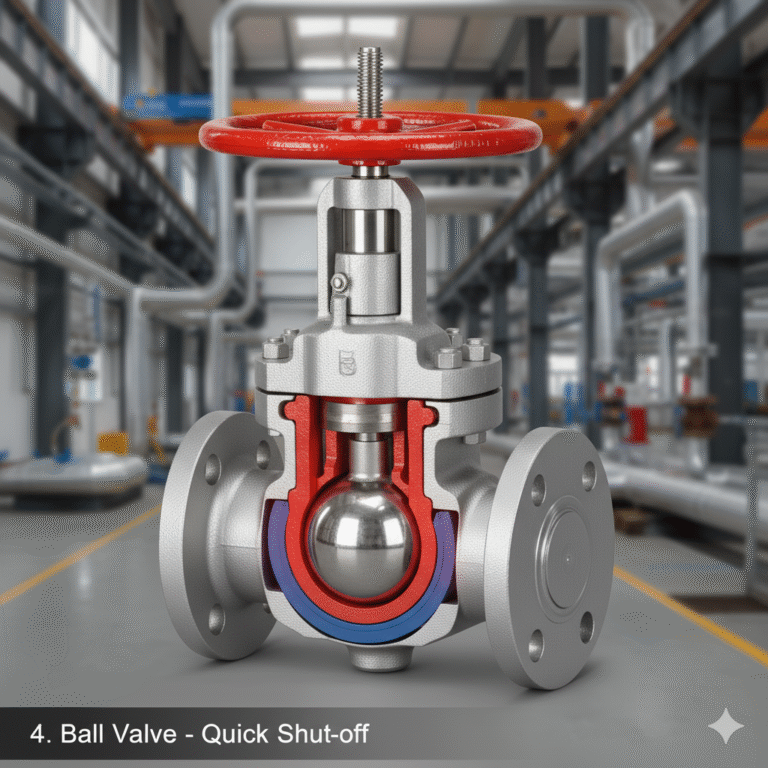

4. Ball Valve

Definition and Structure

A ball valve uses a spherical ball as the closing element. The ball rotates 90° to open or close the valve.

Advantages

Extremely low fluid resistance, almost negligible.

Reliable performance in corrosive media and low-boiling liquids.

Stable sealing over a wide range of pressures and temperatures.

Quick opening and closing, with some designs operating in 0.05–0.1 seconds.

Can be used in buried pipelines without worrying about corrosion.

Disadvantages

The sealing material, usually PTFE, has a high thermal expansion coefficient and is sensitive to temperature and cold flow.

PTFE can only be used reliably at temperatures below approximately 180°C.

Not as effective for flow regulation, especially in pneumatic/electric control applications.

Application Scenarios and Selection Tips

Suitable for quick opening and closing, high-pressure, and corrosion-resistant environments, such as oil and gas pipelines and chemical systems. When selecting, consider whether flow regulation or high temperatures are required.

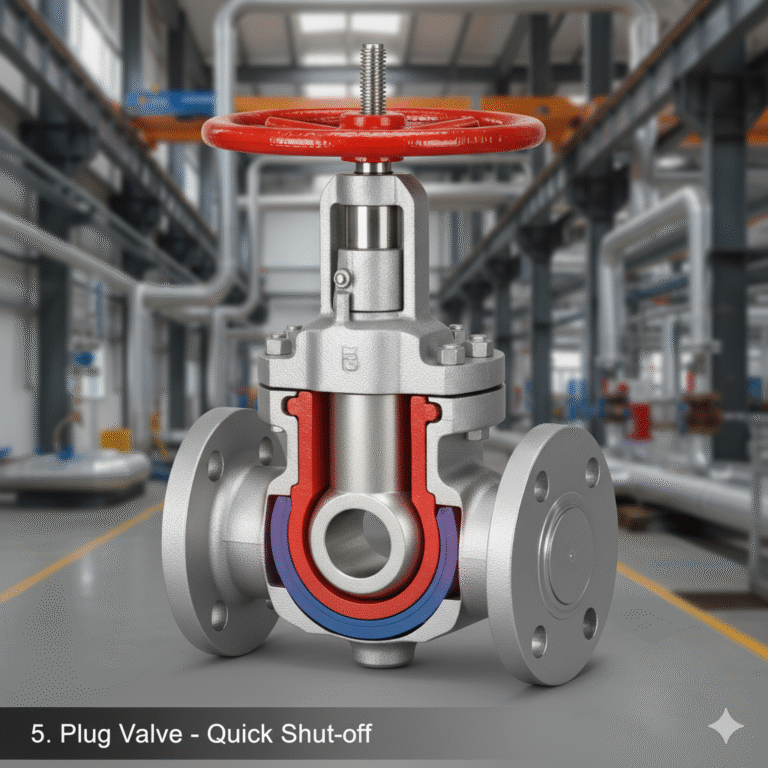

5. Plug Valve

Definition and Structure

A plug valve uses a cylindrical or conical plug that rotates to align or block the passage of fluid.

Advantages

Suitable for frequent operation and quick opening/closing.

Low fluid resistance, simple structure, and compact size.

Excellent sealing performance with fewer installation restrictions.

Disadvantages

Larger sealing surface area may require more torque to operate.

Limited by size and flow rate for certain applications.

Application Scenarios and Selection Tips

Commonly used in industries like petrochemicals and mining where frequent operation and fluid isolation are required. When selecting, consider the torque needed, seal wear, and maintenance requirements.

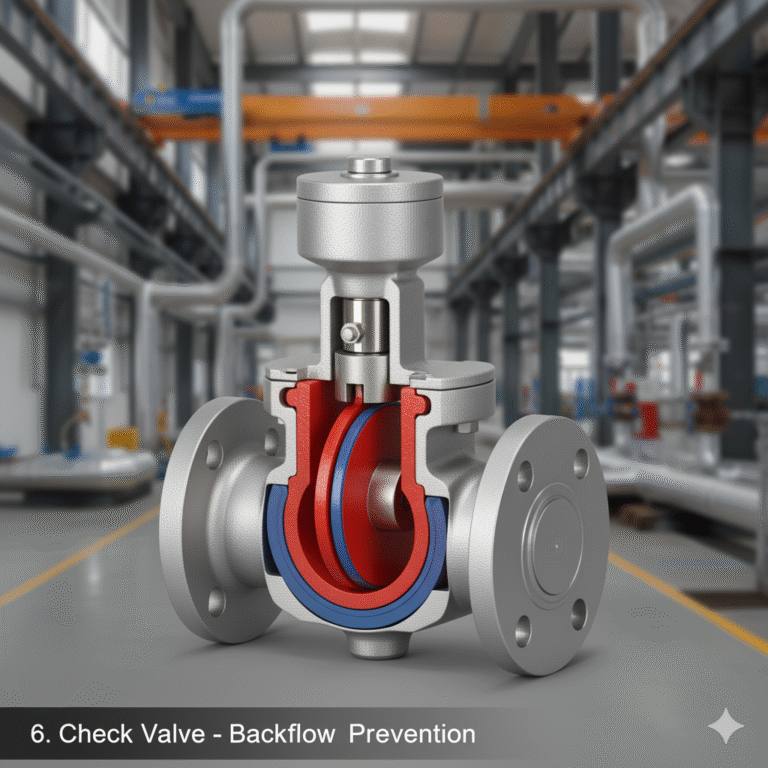

6. Check Valve

Definition and Structure

Check valves prevent backflow in a pipeline, featuring various designs such as lift check, swing check, and butterfly check valves.

Advantages

Simple structure, easy to maintain, and cost-effective.

Compact, low fluid resistance with good sealing performance, especially in large pipelines.

Disadvantages

Lift check valves can produce significant noise.

Swing check valves are more complex and have higher manufacturing costs.

Butterfly check valves may require additional space for the valve disc.

Application Scenarios and Selection Tips

Ideal for systems that require backflow prevention, such as pump outlets, hot water circulation, and cooling systems. When selecting, consider factors such as space availability and noise tolerance.

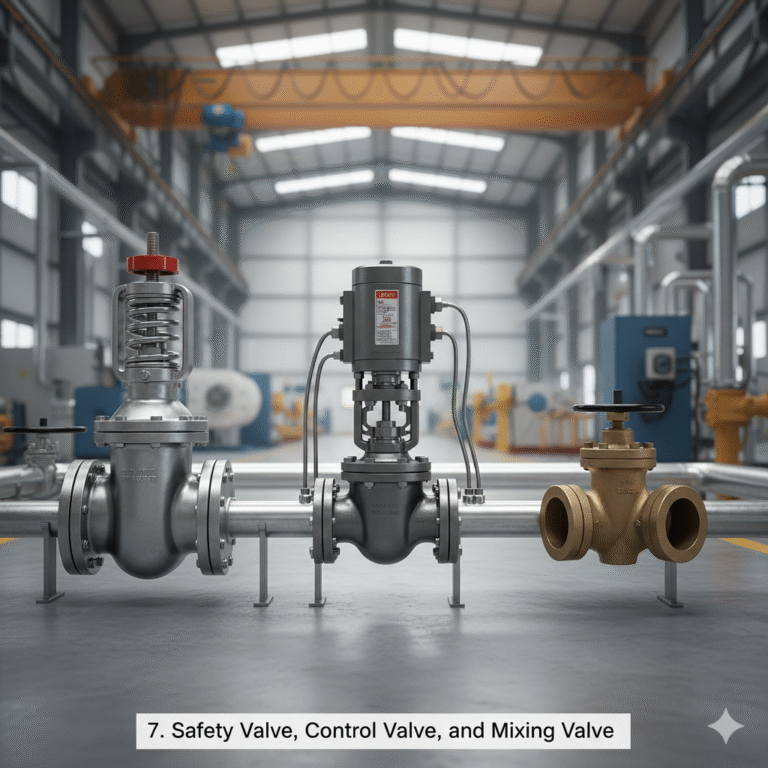

7. Safety Valve, Control Valve, and Mixing Valve

Safety Valve

Used for pressure relief when system pressure exceeds a set limit, automatically releasing pressure and closing once the system pressure normalizes.

Often used in boilers, pressure vessels, and steam systems.

Control Valve

Used to regulate flow, pressure, and temperature in a process control system.

Ideal for chemical, petrochemical, and HVAC systems.

Mixing Valve

Used for fluid distribution, mixing, or separation in complex process flows.

Selection depends on the flow rate, pressure, and material compatibility.

8. Conclusion and Selection Recommendations

When selecting a valve, consider the purpose: Is it for simple on/off operation, flow/pressure regulation, backflow prevention, or safety relief? Then evaluate key operating conditions such as the medium type (liquid, gas, slurry), temperature, pressure, flow direction, and installation constraints.

Common Valve Selection Guidelines:

Gate valve for minimal flow resistance and long-term operation.

Globe valve for precise flow control and frequent opening/closing.

Butterfly valve for large-diameter, low-pressure systems.

Ball valve for fast shut-off and corrosion resistance.

Check valve for backflow prevention.

Safety valve for pressure relief.

Ensure the selected valve meets the application’s requirements while considering the differences in size, material, and design.