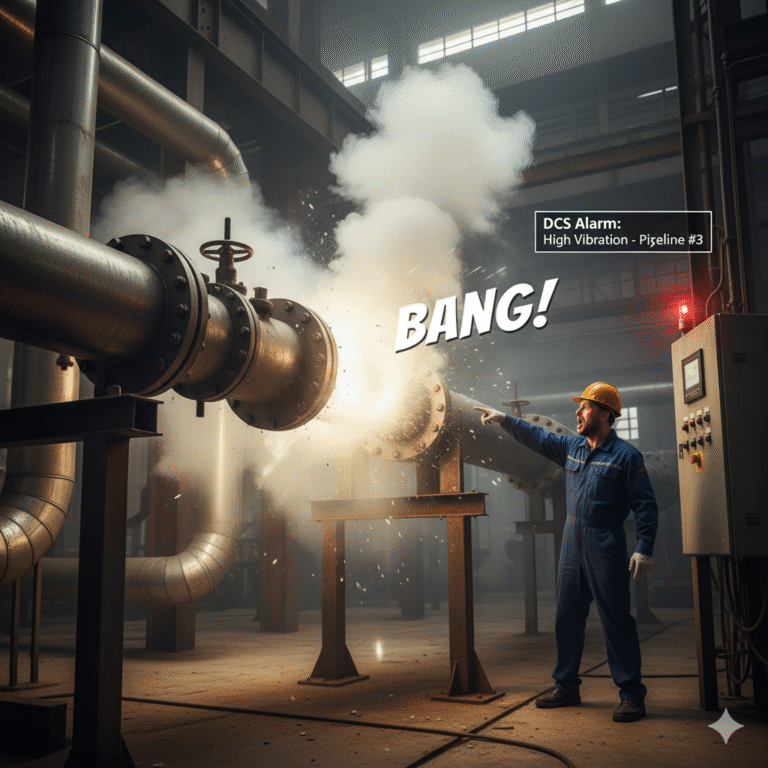

In the field, many operators have experienced this moment: despite following procedures, the moment the steam valve is opened, a dull “bang” is heard from the pipeline, the steel pipes shake, and white steam rises from the flanges… This is a classic case of steam pipeline water hammer. If not addressed immediately, it can cause equipment damage, shutdowns, or even accidents within seconds.

1. Identifying Water Hammer in Time

Water hammer is easy to identify with its distinctive symptoms:

A sudden drop in steam temperature and pressure fluctuations

A dull “bang” sound from the pipeline

Noticeable vibrations in the pipeline and supports

White steam emanating from the flanges, and possible leaks

Frequent DCS alarms and abnormal parameter fluctuations

When these signs appear, don’t hesitate – water hammer is at the door!

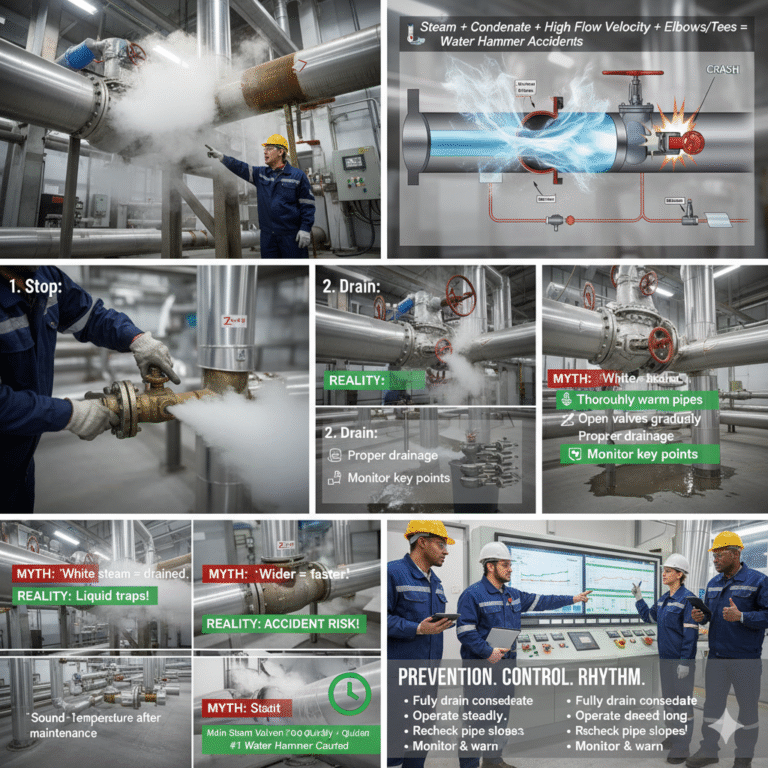

2. Why Does Water Hammer Occur?

Many believe water hammer is an “isolated problem,” but in reality, it’s often caused by multiple factors. For example, during the pipe warm-up process, incomplete draining of condensate can create a hidden hazard. When the boiler is overfilled, steam-water separation occurs, or load fluctuations happen, large amounts of water can be carried by the steam, triggering water hammer. Pipe design flaws, such as improper slope or incorrect drainage point placement, exacerbate the risk. Furthermore, sudden opening of the main steam valve can “push” water through the system. If the monitoring system is slow to respond and fails to identify abnormal signals in time, the water hammer problem becomes even more likely.

Key Factors for Water Hammer:

Steam + condensate + high flow velocity + elbows/tees = water hammer accidents.

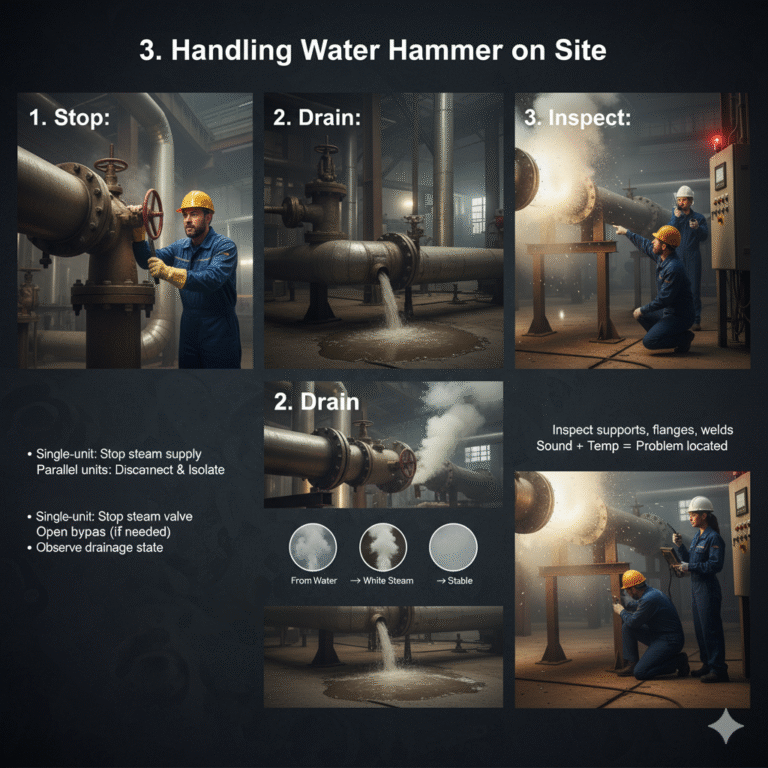

3. Handling Water Hammer on Site

When water hammer occurs, stay calm and follow a systematic approach:

Stop:

For single-unit operation, stop steam supply immediately.

For parallel units, disconnect the abnormal side and isolate it.

Drain:

Open the lowest point drain valve to expel condensate.

If necessary, open the bypass of the drain valve.

Observe the drainage state: from water → white steam → stable.

Inspect:

Lock down the vibration area to check for liquid traps.

Inspect supports, flanges, and welds.

Communicate with the turbine to prevent cascading effects.

Use “sound + temperature + drainage state” to quickly locate the problem.

4. Prevention Is Better Than Cure

The best way to handle water hammer is to prevent it from happening in the first place. Key preventive measures include:

Operational Measures:

Thoroughly warm the pipes and drain condensate before starting steam supply.

Open the main steam valve in stages, starting with a small opening.

Gradually increase pressure and temperature without rushing.

Equipment Measures:

Ensure drainage points are placed at the lowest points and remain unobstructed.

Replace faulty steam traps promptly; don’t delay.

After maintenance, recheck pipe slopes to prevent hidden hazards.

Monitoring Measures:

Strengthen monitoring of key temperature and vibration points.

Establish alarm curves and “identification standards” for early warnings.

Advance early warnings to reduce risk.

5. Real-World Case

During winter maintenance at a power plant, after the initial steam supply, a loud “bang” suddenly echoed from downstream of the branch pipe of the connection manifold:

The downstream pipe vibrated intensely.

The support slightly deformed, and white steam appeared at the flange.

The operation log showed the main steam valve was opened too quickly, and condensate was not fully drained.

Measures Taken:

Steam supply was stopped immediately.

Condensate was drained.

Pipe slope was adjusted.

The steam supply was resumed in stages.

Although this incident didn’t cause major damage, it was a wake-up call for the entire plant. From then on, “draining condensate” was included in the pre-startup checklist.

6. Common Misconceptions

“If white steam is coming out, the condensate is completely drained.” Wrong! There may still be liquid traps.

“Opening the valve wider makes the process faster.” But it also increases the likelihood of accidents.

“No need to recheck after maintenance.” Changes in pipe slope can lead to hidden risks.

“Warm-up doesn’t need to take long.” This is the most common cause of water hammer!

Water hammer can be highly destructive. Even if it’s just a small noise, it must be taken seriously.

7. Final Thoughts

Water hammer is not a random event, nor is it a result of “bad luck.” It’s often the result of neglecting small details. Preventing water hammer relies on controlling these details, and handling it properly requires maintaining the right rhythm. For example, ensure condensate is fully drained, operate steadily, recheck pipe slopes after maintenance, and never ignore monitoring and warning signals.

Make these practices a habit, and water hammer will no longer “sneak up on you.”