Reed switch level sensors and magnetostrictive level sensors are two common technologies used for liquid level measurement. These two sensors differ in their operating principles, applications, and performance characteristics. Below is a comparison of the two.

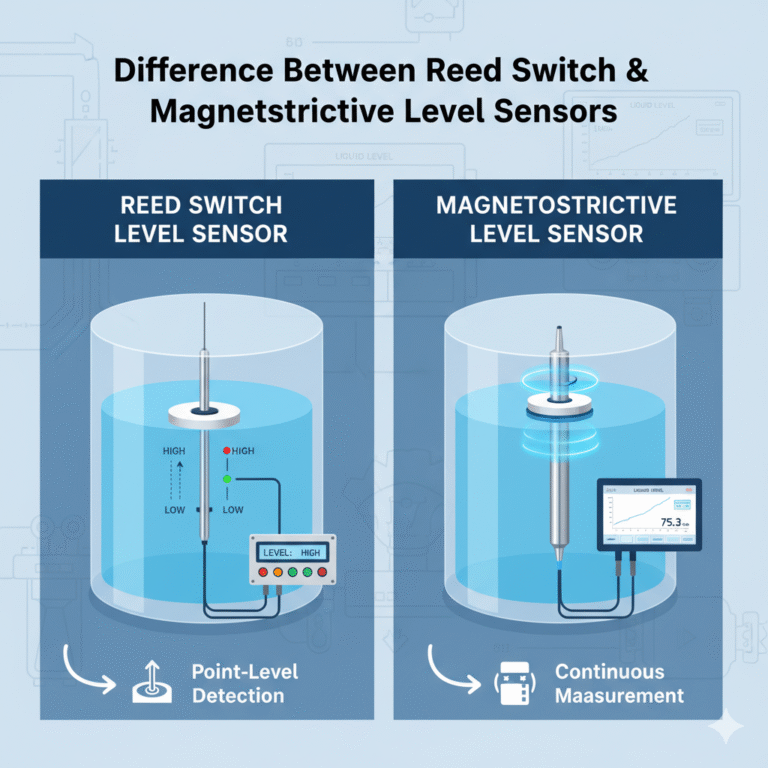

1. Operating Principle

Reed Switch Level Sensors:

Reed switch level sensors operate based on the interaction between a reed switch (a sealed metal tube containing contacts) and a float. As the liquid level changes, the float rises or falls, causing the reed switch to open or close. This action triggers a signal to indicate the liquid level. Reed switch sensors are generally used for point-level detection.Magnetostrictive Level Sensors:

Magnetostrictive level sensors work based on the magnetostrictive effect. A magnetic float moves as the liquid level changes, generating a magnetic field. This magnetic field interacts with a sensor that drives a probe, causing it to elongate or contract. The change is detected and translated into a continuous liquid level measurement. This type of sensor provides precise and continuous liquid level data.

2. Measurement Type

Reed Switch Level Sensors:

These sensors are suited for point-level measurement, meaning they can only indicate whether the liquid has reached a certain set point, but they cannot provide precise height measurements.Magnetostrictive Level Sensors:

These sensors offer continuous liquid level measurement, providing accurate and real-time data on the liquid’s height, making them ideal for ongoing monitoring and data recording.

3. Accuracy and Stability

Reed Switch Level Sensors:

Reed switch sensors are less accurate and generally used for simple level control applications. They can be affected by environmental factors such as temperature and pressure, leading to reduced stability.Magnetostrictive Level Sensors:

These sensors provide high accuracy and stability, capable of delivering high-resolution continuous level readings. They are less influenced by changes in temperature or pressure and can operate in challenging environments.

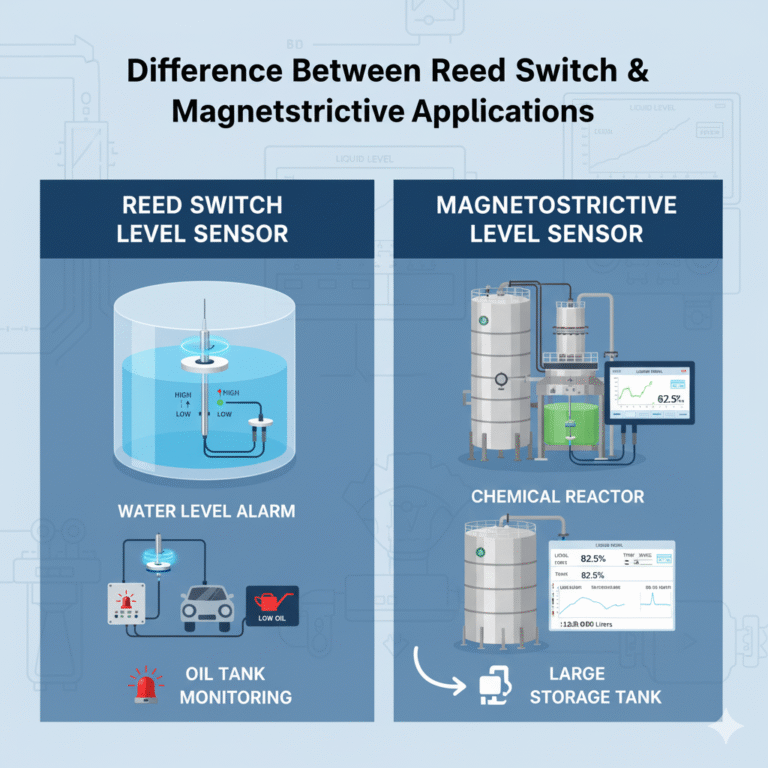

4. Applications

Reed Switch Level Sensors:

Reed switch sensors are commonly used in applications where high precision is not required, such as water level alarms, oil level monitoring, and other low-cost point-level measurements.Magnetostrictive Level Sensors:

Magnetostrictive sensors are ideal for applications that require precise, continuous level monitoring, such as in the chemical, oil, and food industries, for large storage tanks, reactors, and other complex vessels.

5. Installation

Reed Switch Level Sensors:

Reed switch sensors have a simple structure and are easy to install. They typically involve a float and reed switch assembly, which is easy to set up.Magnetostrictive Level Sensors:

Magnetostrictive sensors are more complex and require careful installation to ensure proper alignment of the sensor and float. Installation costs are generally higher.

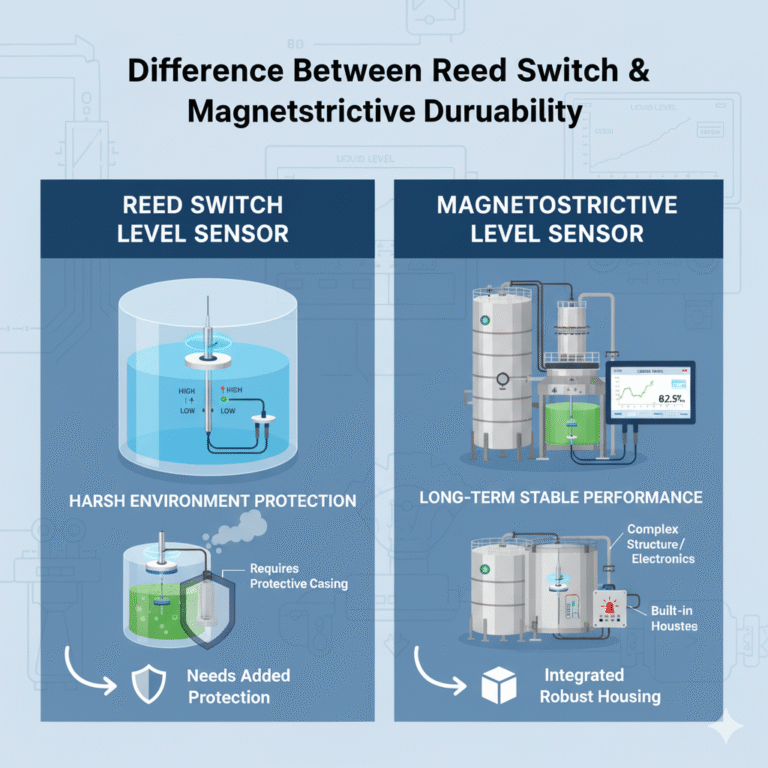

6. Durability

Reed Switch Level Sensors:

These sensors are fairly durable due to their simple operation. However, they may require additional protection in harsh environments, such as high temperatures or corrosive liquids.Magnetostrictive Level Sensors:

Magnetostrictive sensors are generally more durable, but due to their complex structure and the involvement of electronic components, they require better protection to ensure long-term, stable performance.

Summary

Reed switch level sensors are well-suited for basic point-level detection applications. They are cost-effective but less accurate, making them ideal for simple monitoring needs.

Magnetostrictive level sensors offer high-precision continuous level measurements. Though more expensive, they are ideal for industrial applications requiring accurate and reliable level monitoring.

Both sensors have their unique advantages, and the choice between them depends largely on the application requirements and budget constraints.