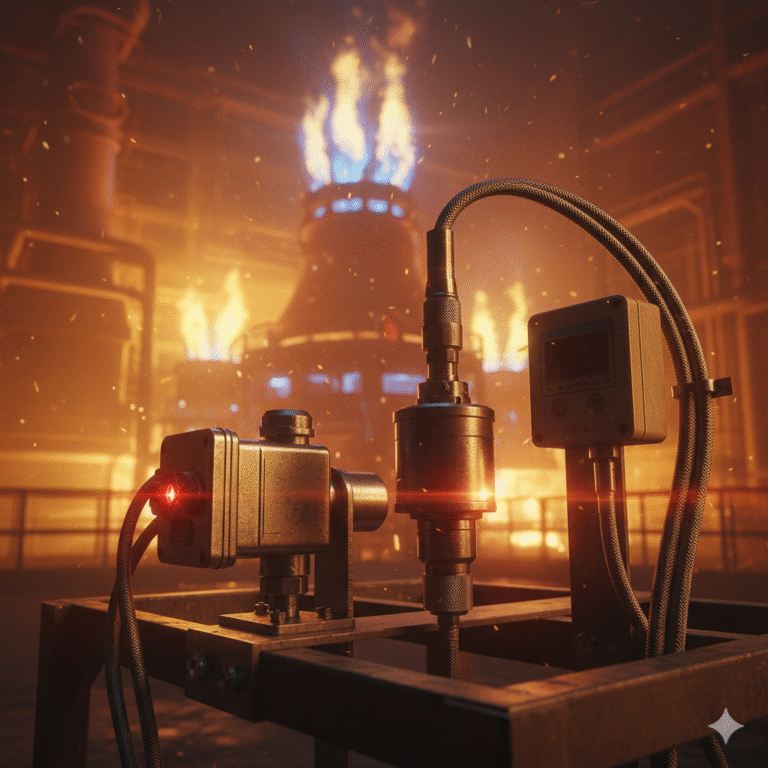

Ensuring that instruments operate properly in high-temperature environments requires a comprehensive approach involving selection, installation, protection, and maintenance. Different types of instruments, such as sensors, transmitters, and displays, require tailored solutions. The following strategies outline how to address these needs:

1. Selection: Choose High-Temperature Models

1.1. Core Component Temperature Compatibility

Sensors: Choose sensors made from high-temperature-resistant materials (e.g., platinum-rhodium alloys for thermocouples, capable of withstanding temperatures above 1600°C; pressure sensor diaphragms made from Hastelloy or tantalum, withstanding temperatures up to 400°C).

Electronic Components: Select high-temperature chips (with operating temperatures ranging from -55°C to 150°C or higher), avoiding the use of standard components that may fail due to heat-induced aging (e.g., ceramic-packaged capacitors and resistors).

Casing and Connectors: Use high-temperature alloys like 310S stainless steel, ceramics, or mica, instead of standard plastics or carbon steel, to prevent deformation or melting at elevated temperatures.

1.2. Instrument Type Compatibility

Avoid Mechanical Structure-Dependent Instruments: Instruments like float-type level gauges may become stuck in high temperatures. Instead, use non-contact instruments (e.g., radar level gauges, which can withstand temperatures above 300°C) or fiber optic sensors (completely resistant to high temperatures).

Power Supply: For powered instruments, choose wide-temperature range power modules (e.g., -40°C to 85°C), to prevent overload and damage under high-temperature conditions.

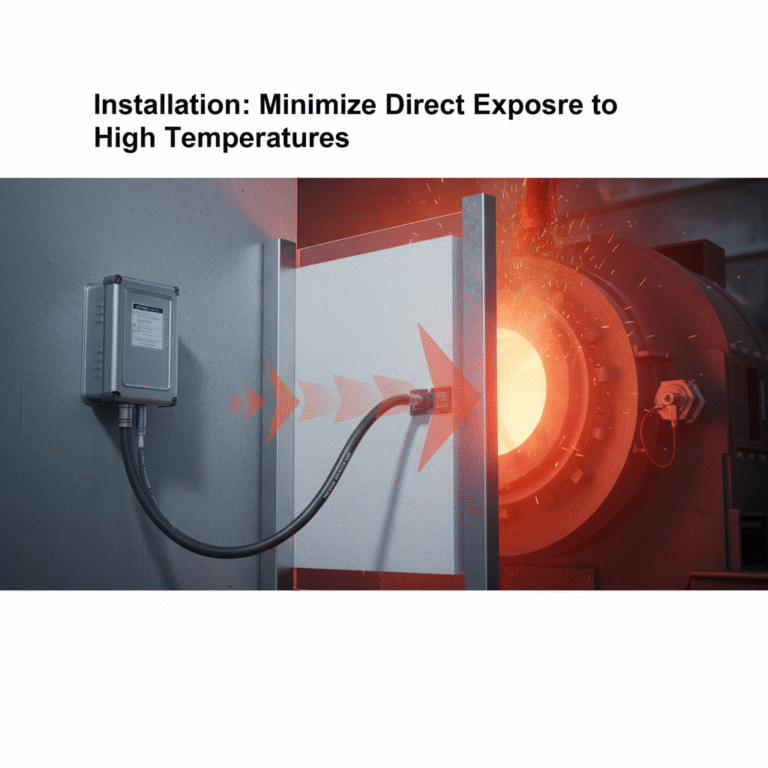

2. Installation: Minimize Direct Exposure to High Temperatures

2.1. Physical Isolation from Heat Sources

Thermal Insulation: Use asbestos sheets, ceramic fiber boards, or metal barriers between the instruments and high-temperature equipment (e.g., boilers or reactors) to block thermal radiation.

Distance from Heat Sources: Install instruments in well-ventilated, cooler areas (e.g., away from pipe flanges or heating devices). If necessary, extend sensor cables using high-temperature cables (e.g., PTFE-insulated cables, which can withstand temperatures up to 260°C), to move the instrument away from the heat zone.

2.2. Forced Cooling

Natural Ventilation: Ensure enough space (≥30cm) around the instrument for airflow to avoid heat buildup.

Active Cooling: For extremely high-temperature environments (e.g., above 500°C), install forced air cooling (e.g., compressed air blowers) or water cooling jackets (circulating water to lower the temperature), keeping the instrument’s surface temperature within acceptable limits (e.g., ≤80°C).

3. Operational Protection: Real-Time Monitoring and Environmental Control

3.1. Temperature Monitoring and Protection

Install Temperature Sensors: Use temperature sensors around instruments to monitor environmental temperature. Set alarms (visual, audible) or automated systems to cut power if temperatures exceed preset limits to avoid prolonged exposure to high heat.

Overheat Protection Circuits: For sensitive instruments, integrate internal overheat protection (e.g., temperature fuses, thermal relays) that shut off power automatically when the temperature exceeds a safe threshold, with automatic restart when the temperature drops to a safe level.

3.2. Environmental Temperature Control

Climate Control in Enclosed Spaces: Install air conditioning or industrial coolers in control rooms or other enclosed spaces to maintain a temperature range within the instrument’s rated operating range (typically 0-50°C).

Outdoor Protection: For instruments exposed to direct sunlight in hot environments, use sunshields or rain covers to protect them from thermal fluctuations caused by direct sun exposure.

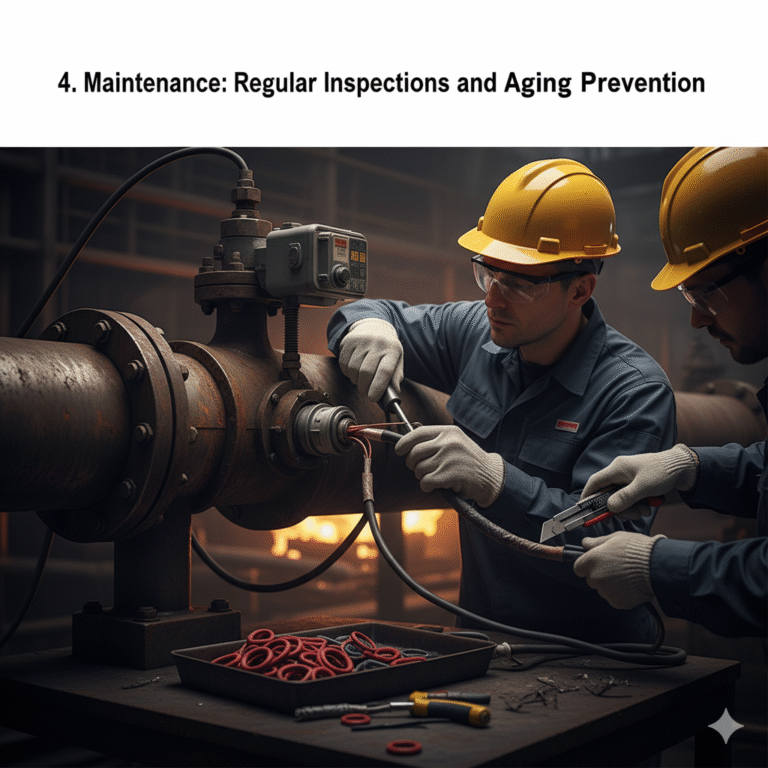

4. Maintenance: Regular Inspections and Aging Prevention

4.1. Regular Cleaning and Inspections

Surface Cleaning: Clean the instrument’s surface regularly to remove dust and oil, as contaminants can carbonize at high temperatures, affecting heat dissipation.

Check Connections: Regularly inspect terminal connections to prevent oxidation or loosening caused by high temperatures. Tighten or replace connectors with high-temperature-rated materials (e.g., ceramic terminals).

Lubrication of Mechanical Components: For mechanical components like valves and actuators, apply high-temperature lubricants (e.g., molybdenum disulfide grease) to prevent jamming at high temperatures.

4.2. Preemptive Replacement of Aging Components

Seals and Insulation: Seals (e.g., O-rings) and cable insulation materials are prone to aging under high temperatures. Inspect these components every 3-6 months, and replace cracked or hardened seals with high-temperature-resistant materials (e.g., fluoroelastomers, which can withstand temperatures up to 300°C).

Life Cycle Management: Plan for the early replacement of instruments that have been in operation for extended periods. High temperatures can shorten the lifespan by up to 50%, so proactive replacement can help avoid unexpected failures.

5. Special Considerations for Extreme Scenarios

High Radiation and Temperature: In environments with strong thermal radiation (e.g., near furnaces), use radiation-resistant materials (e.g., lead or nickel alloy shields) to reduce heat exposure.

Fluctuating Temperatures: For environments with fluctuating temperatures, use instruments with wide operating temperature ranges (e.g., -40°C to 125°C) to prevent fatigue caused by repeated thermal expansion and contraction of components.

Conclusion

By implementing the above strategies, it is possible to effectively mitigate the impact of high temperatures on instruments. The key is to focus on “heat avoidance at the source, proactive heat dissipation, and regular maintenance” to ensure stable instrument operation in high-temperature environments.