1. The Debate: IIoT vs. DCS — Rivalry or Reinvention?

A recent trending article claimed that the Industrial Internet of Things (IIoT) will “replace DCS and lead the era of Industrial Revolution 5.0.”

It reignited a long-standing argument in the automation community — can IIoT truly replace the Distributed Control System (DCS)?

Supporters of this view emphasize that the next generation of smart manufacturing demands human-machine collaboration, intelligent interconnection, and global optimization. These goals, they argue, exceed the limitations of traditional DCS systems that rely on local closed loops, rigid functions, and limited data visibility.

On the other hand, many automation experts respond firmly:

“Only automation can replace automation.”

Their stance is simple — IIoT was never designed to perform real-time process control. The role of IIoT is not to replace automation, but to expand and empower it.

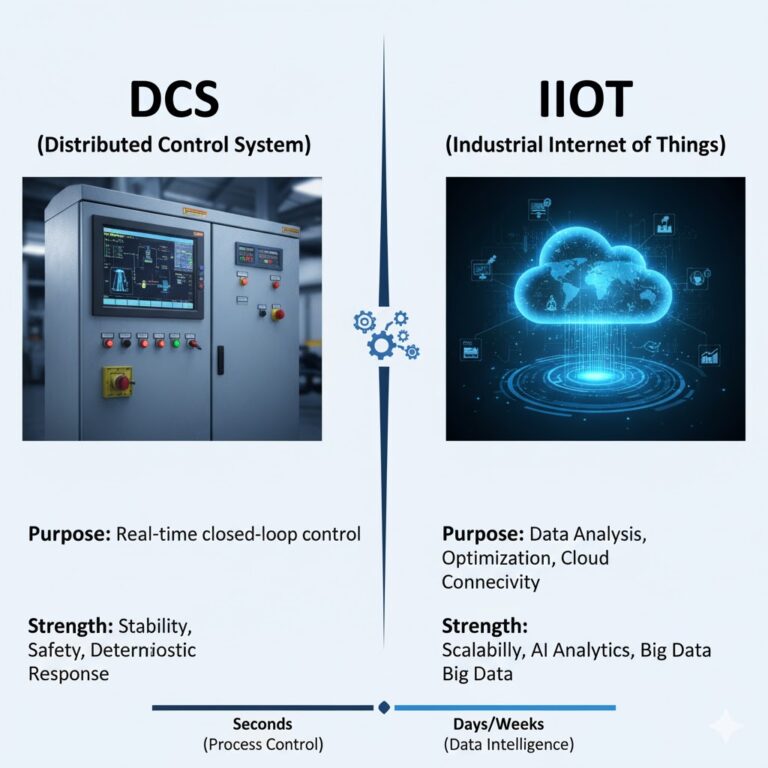

2. Understanding the Core Difference

To understand the debate, we must clarify what each system is built for.

| System | Purpose | Core Strengths |

|---|---|---|

| DCS (Distributed Control System) | Real-time closed-loop control of industrial processes | Deterministic response, stability, redundancy, safety |

| IIoT (Industrial Internet of Things) | Integration, monitoring, data analysis, and cloud connectivity | Open connectivity, big data, AI analytics, scalability |

In essence:

DCS controls what happens in seconds.

IIoT understands what happens over days, weeks, or across multiple plants.

DCS ensures process reliability; IIoT drives data intelligence.

They are not on the same layer of industrial control hierarchy — DCS sits at the control layer, while IIoT operates at the information and optimization layer.

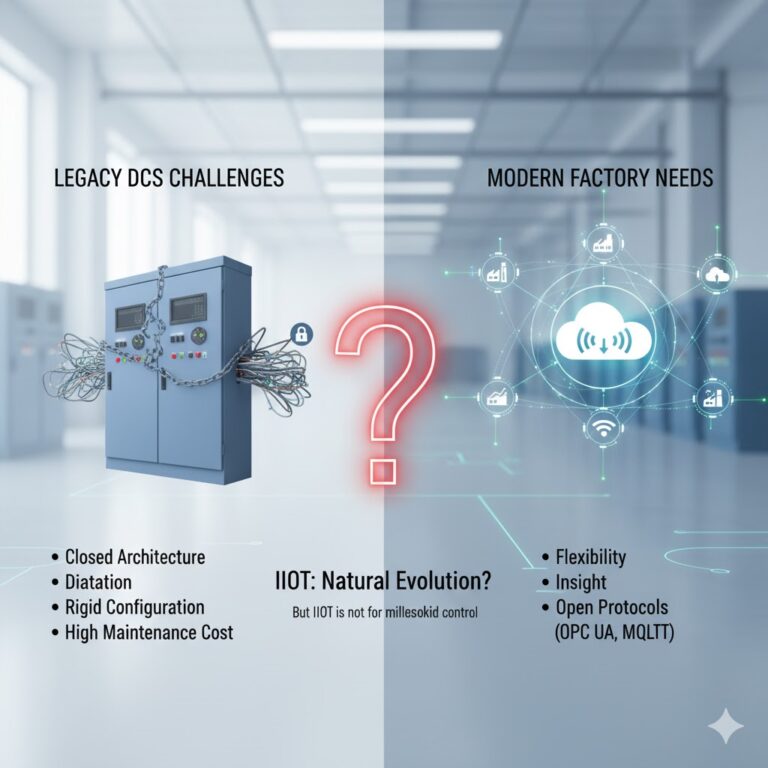

3. Why the “Replacement” Theory Emerged

Despite their differences, the idea of IIoT replacing DCS didn’t appear from nowhere. It stems from the growing mismatch between modern manufacturing needs and legacy DCS architectures.

Traditional DCS systems face several challenges:

Closed architecture: Vendor-locked systems make integration expensive.

Rigid configuration: Logic modification often requires shutdowns or revalidation.

Data isolation: Real-time control data rarely reaches MES or ERP systems.

High maintenance cost: Hardware-centric design increases lifecycle expenses.

Meanwhile, IIoT platforms — with edge-cloud collaboration, open protocols (OPC UA, MQTT, RESTful APIs), and AI-driven analytics — offer exactly what modern factories crave: flexibility, connectivity, and insight.

This leads some to claim that IIoT is the “natural evolution” of DCS.

However, this statement overlooks one key fact: IIoT is not designed for millisecond-level control. Real-time deterministic control, safety loops, and interlocks remain the domain of automation systems.

What’s actually happening is functional convergence, not replacement.

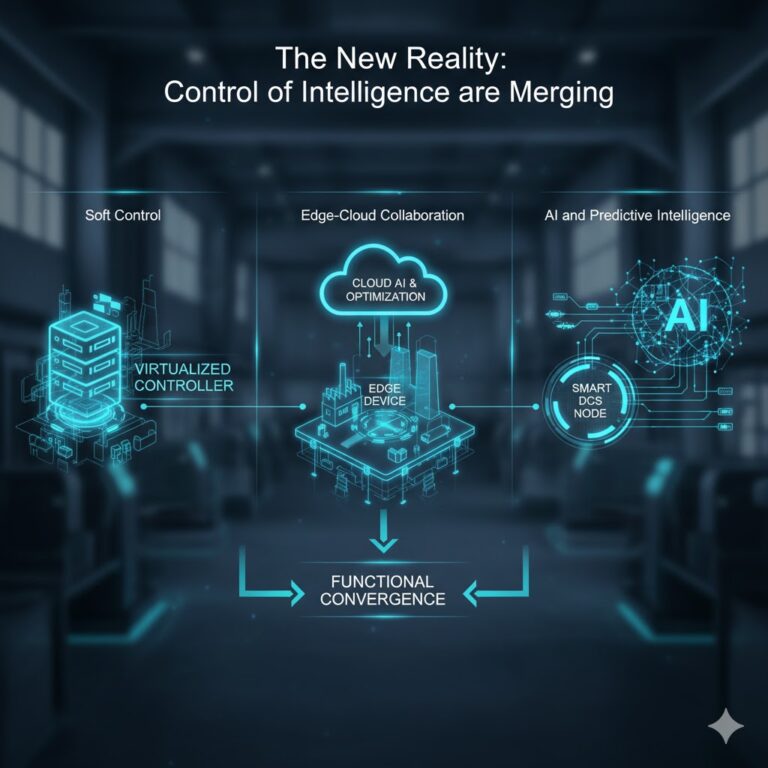

4. The New Reality: Control and Intelligence are Merging

The future industrial architecture is no longer a simple hierarchy — it’s a distributed intelligence network.

⚙️ 4.1. From Control Hardware to Soft Control

Virtualized controllers and software-based PLC/DCS environments are emerging rapidly. These “soft controllers” run on industrial PCs or edge servers, bringing flexibility and scalability.

They still perform real-time control, but now they can also communicate natively with IIoT platforms — sending performance data, receiving optimization parameters, and enabling cloud-assisted tuning.

☁️ 4.2. Edge-Cloud Collaboration

Instead of the DCS being an isolated island, the edge layer now bridges control and cloud.

Edge devices collect high-frequency process data and execute control algorithms locally.

Cloud systems perform AI analysis, model training, and long-term trend prediction.

This hybrid model ensures both real-time responsiveness and global optimization.

🤖 4.3. AI and Predictive Intelligence

By analyzing thousands of process variables over time, AI can predict abnormal conditions or optimize PID tuning automatically.

The DCS doesn’t disappear — it becomes a smart node within an intelligent ecosystem orchestrated by IIoT.

5. Industrial Revolution 5.0: Redefining, Not Replacing

Industrial Revolution 5.0 is often summarized as human-machine collaboration and intelligent orchestration.

In this context, the relationship between DCS and IIoT should be understood as symbiotic, not competitive.

| Stage | Focus | Control Logic | Information Flow |

|---|---|---|---|

| Industry 3.0 | Automation & PLC/DCS | Hardware-based | Vertical (shop-floor only) |

| Industry 4.0 | Digitalization & IIoT | Integrated, partly cloud-enabled | Horizontal (cross-system) |

| Industry 5.0 | Human-AI Collaboration | Virtualized control, AI-driven | Global (edge-to-cloud) |

In this new era, automation and digitalization are inseparable.

DCS is being reborn inside IIoT architectures — as software, as virtual control nodes, and as part of a unified edge-cloud continuum.

The correct question is not “Will IIoT replace DCS?”,

but “What will DCS evolve into within the IIoT ecosystem?”

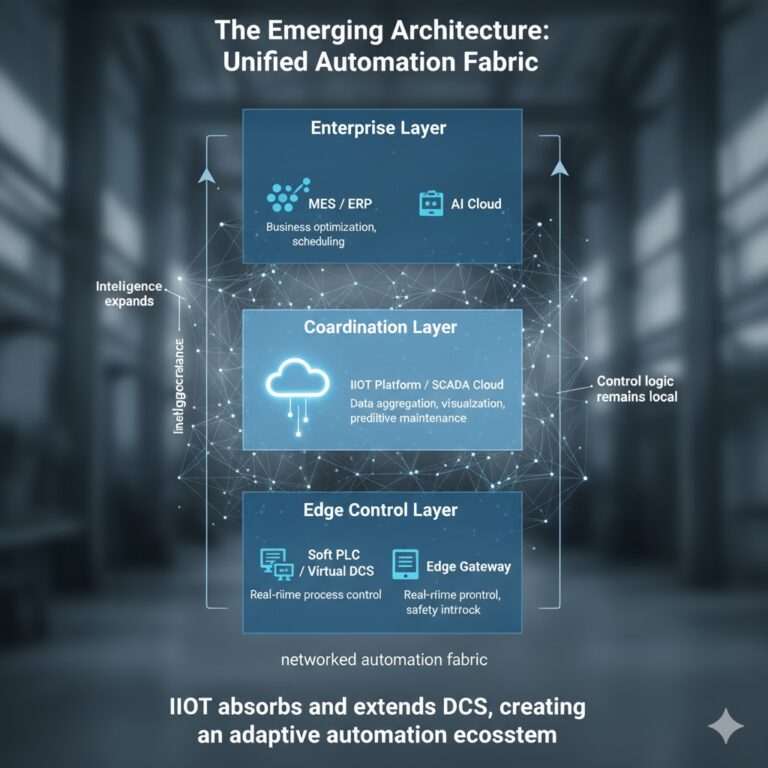

6. The Emerging Architecture: Unified Automation Fabric

The next-generation control architecture will look more like a networked automation fabric than a traditional pyramid.

Three-Layer Integration Model:

| Layer | System Type | Main Functions |

|---|---|---|

| Edge Control Layer | Soft PLC / Virtual DCS / Edge Gateway | Real-time process control, data acquisition, safety interlock |

| Coordination Layer | IIoT Platform / SCADA Cloud | Data aggregation, visualization, predictive maintenance, AI analytics |

| Enterprise Layer | MES / ERP / AI Cloud | Business optimization, scheduling, quality traceability, energy management |

In this architecture, control logic remains close to the process, but intelligence expands across the enterprise.

IIoT doesn’t eliminate DCS — it absorbs and extends its capabilities, creating a flexible and adaptive automation ecosystem.

7. Practical Implications for Industry

For End Users:

Openness: Avoid vendor lock-in; choose systems supporting open protocols and modular integration.

Scalability: Start from data collection, evolve toward full IIoT-driven optimization.

Resilience: Keep safety-critical controls local, but let cloud intelligence guide optimization.

For System Integrators:

Embrace virtual PLCs and edge controllers as the next evolution of DCS.

Focus on data modeling, analytics, and AI-driven process improvement.

Develop hybrid architectures — real-time at the edge, intelligence in the cloud.

For Automation Vendors:

Transition from selling “hardware control systems” to providing “automation ecosystems”.

Integrate IIoT platforms natively with DCS/PLC products to enable end-to-end digital twins.

Support open standards and interoperability as a strategic priority.

8. Final Thoughts: The Future is Convergence

IIoT is not the enemy of DCS — it is its next incarnation.

The industrial world is moving from deterministic control islands to collaborative, intelligent networks.

In Industrial Revolution 5.0, control systems will no longer live in isolation. They will communicate, learn, and optimize together — powered by IIoT, edge computing, and AI.

So, the answer is clear:

IIoT will not replace DCS. It will redefine it.

The factories of the future will not choose between them — they will combine both into one intelligent, adaptive automation fabric.