Introduction

In the full lifecycle of process instrumentation, maintenance is not a single-stage activity but a continuous, evolving strategy. Preventive, predictive, and proactive maintenance are not isolated tasks performed at different times—they form a progressive reliability chain that connects time, condition, and root cause.

The earlier and deeper these three dimensions are integrated, the longer an instrument remains in its “high-reliability and low-cost” zone on the lifecycle curve. This article explains how these maintenance strategies complement each other and how they can be implemented across different stages of an instrument’s lifecycle.

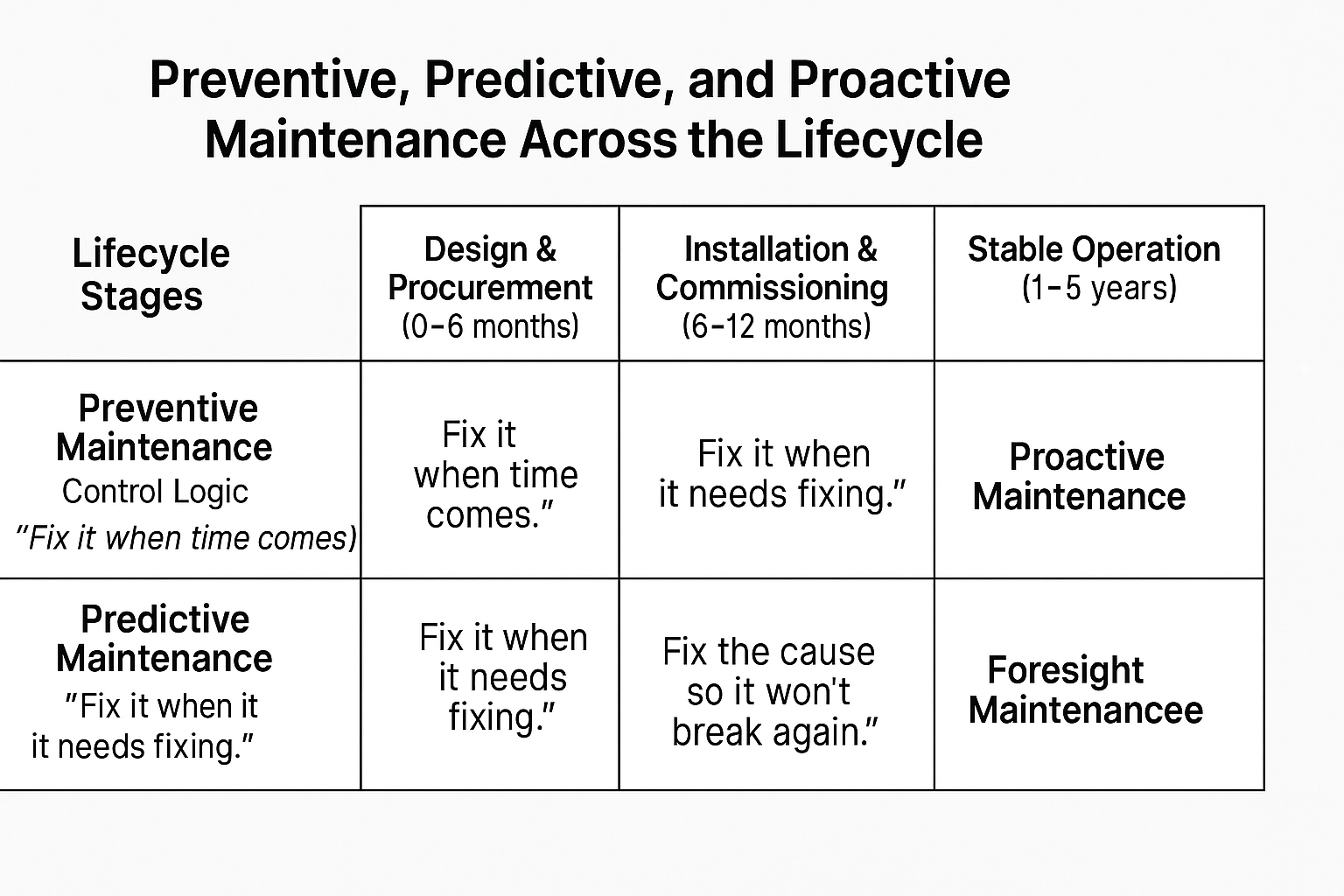

1. Lifecycle Stages and Maintenance Dimensions

| Maintenance Type | Control Logic | Strategy Focus | Mindset |

|---|---|---|---|

| Preventive Maintenance (PM) | Time-based — “Fix it when time comes.” | Scheduled interventions to prevent wear-out failures. | Compliance |

| Predictive Maintenance (PdM) | Condition-based — “Fix it when it needs fixing.” | Real-time diagnostics using data and trends. | Insight |

| Proactive Maintenance (ProM) | Root-cause-based — “Fix the cause so it won’t break again.” | Design and process improvements that eliminate recurring failures. | Foresight |

2. Maintenance Applications Across the Lifecycle

1️⃣ Design & Procurement Stage (0–6 months)

Preventive:

Reference historical maintenance cycles of similar plants and include these in the procurement specification—for example, valve packing designed for 12-month replacement, or solenoid valves with manual reset for easy function testing.

Predictive:

Specify smart transmitters (temperature, pressure) with HART or Foundation Fieldbus interfaces to enable future data acquisition and health monitoring.

Proactive:

Perform Root Cause Analysis (RCA) on previous failure events such as “thermowell breakage” or “valve stem re-weld failures.” Then integrate lessons into design standards:

e.g., “Thermowell supports must be fully welded on three sides; valve stem material shall be 17-4PH stainless steel.”

By addressing root causes at the drawing board, you eliminate failure genes before the instrument is even installed.

2️⃣ Installation & Commissioning Stage (6–12 months)

Preventive:

Create three checklists:

Initial calibration record

Loop function test

Loosening prevention markings

Together, these form the baseline maintenance archive.

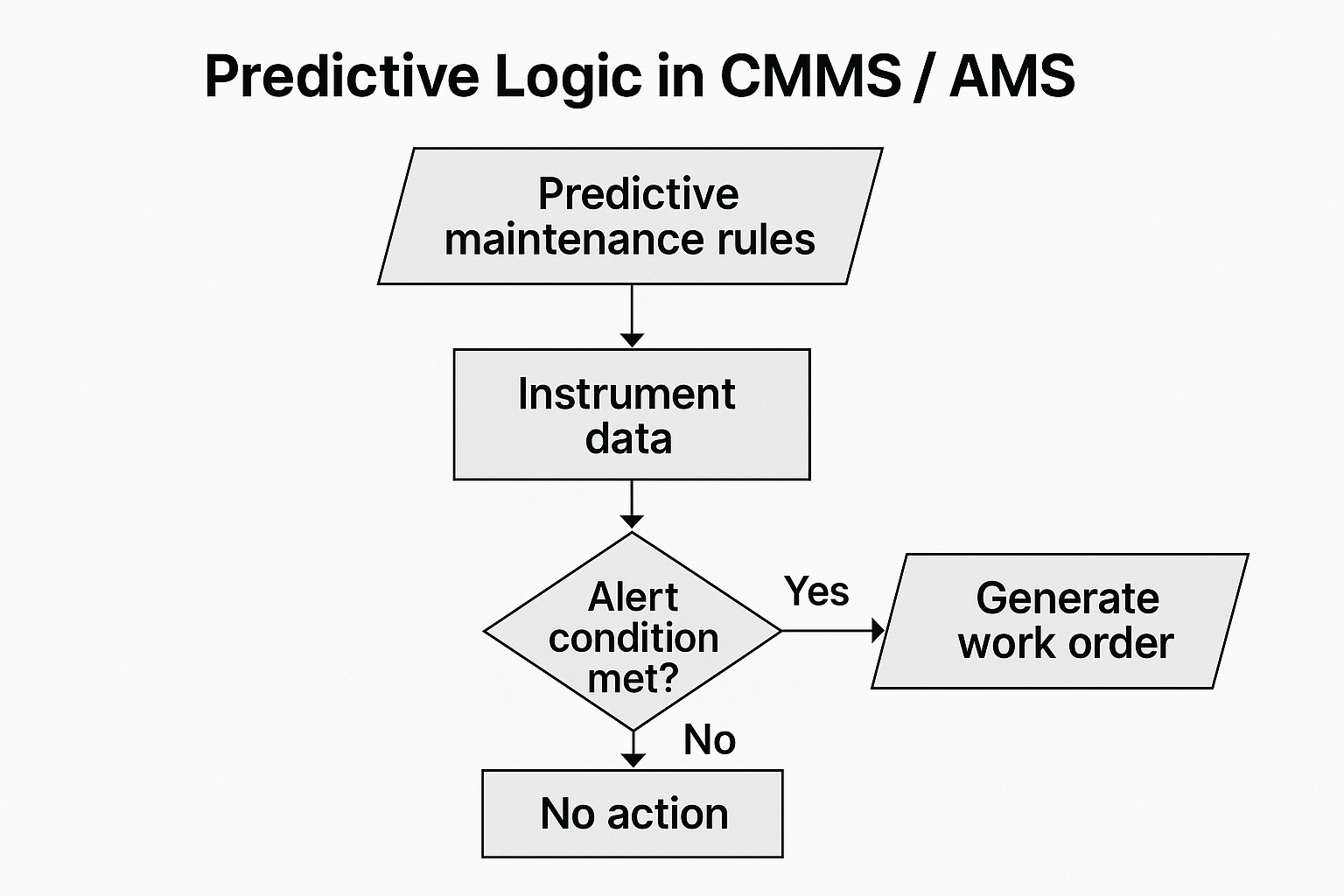

Predictive:

Use an Asset Management System (AMS) to scan all intelligent instruments and log initial drift values as the “zero-kilometer baseline.”

Proactive:

If corrosive conditions (e.g., salt mist) are detected on site, immediately upgrade enclosures from 316L to 2205 duplex stainless steel. This early intervention avoids future pitting corrosion and moisture-induced failures.

3️⃣ Stable Operation Stage (1–5 years) — The Main Battlefield

Preventive:

Use your CMMS (Computerized Maintenance Management System) to automatically generate work orders such as:

Monthly line purging

Quarterly calibration

Annual gasket or seal replacement

For safety-critical (Class A) valves, enforce “mandatory solenoid replacement every two overhaul cycles.”

Predictive:

Temperature loops: The AMS automatically compares thermoresistance drift values monthly.

Deviation > 0.5% → Yellow warning (monitor).

Deviation > 1% → Red alert (schedule repair).

Control valves: When positioner deviation >1.5% or hysteresis >2%, schedule it for the next maintenance window to avoid “stuck stem → unit trip.”

Proactive:

When a false “300 °C temperature spike” appears in a coal-lock system, apply 5-Why Analysis:

Ceramic base cracked → terminal short circuit → false reading.

The corrective action: redesign the terminal using zirconia ceramic base with spring clamps. Result: no recurrence across all units.

4️⃣ Aging & Degradation Stage (5–10 years)

Preventive:

Identify “ten-year replacement” components (e.g., cables, safety barriers, fittings) and lock inventory one year in advance.

Predictive:

Introduce infrared thermography and ultrasonic scanning for condition monitoring:

Hotspot > 10 °C above baseline or partial discharge detected → trend logged and scheduled for next maintenance window.

Proactive:

Discover that 40 A circuit breakers without residual-current protection caused heating-tape fires. As a result, the plant replaces all 145 electric heat-trace lines with metal-shielded, flame-retardant, or steam-traced systems—achieving zero fire incidents thereafter.

5️⃣ Replacement & Renewal Stage (>10 years)

Preventive:

Set a forced retirement rule: any instrument whose cumulative repair cost exceeds 60% of new purchase price shall be replaced.

Predictive:

Use historical failure databases and Weibull life-cycle modeling to estimate remaining MTBF (Mean Time Between Failures) for each batch, deciding whether to replace in full or gradually.

Proactive:

List obsolete devices—those without HART communication or self-diagnostics—as candidates for the next round of modernization. Replace them with SIL2/3-certified smart instruments to enhance safety integrity and operational efficiency.

3. Quantifying the Results — Maintenance ROI

Integrating the three maintenance dimensions yields measurable improvements:

| Metric | Baseline (2023) | After Implementation (2025) | Improvement |

|---|---|---|---|

| Unplanned Shutdowns | 35 cases | 19 cases | ↓ 46% |

| Maintenance Costs | Preventive spending ≈ 12% of annual budget | Emergency repairs reduced by 38% | ≈ 2.8 million RMB saved/year |

| Instrument Life | Thermowells: 4.2 yrs → 6.5 yrs Valves: 18 mo → 30 mo | ↑ > 50% | |

| Safety & Environmental | Flaring and boiler trips due to false signals ↓ 55% in 3 years | ≈ 11,000 tons CO₂ reduced |

4. Implementation Best Practices

🧠 1. Data Integration is Key

Predictive maintenance relies on data fidelity. Integrate data from transmitters, AMS, DCS, and CMMS into a unified dashboard. Real-time health scores allow the maintenance team to act before failures escalate.

🔍 2. Cross-functional Collaboration

Proactive maintenance requires teamwork between instrument engineers, process designers, and maintenance planners. RCA workshops should be part of every shutdown review.

🔧 3. Feedback Loops into Design

Feed every major failure analysis back to the engineering design database. Over time, your design standards evolve from “reaction-based” to “failure-immune.”

📊 4. Quantify and Communicate Results

Tracking metrics—MTBF, downtime hours, cost per failure—helps justify investments to management. Numbers speak louder than narratives.

🌍 5. Digitalization & Smart Upgrades

Adopt IIoT-enabled smart instruments capable of self-diagnostics, Bluetooth access, or Modbus communication. Digital twins can simulate degradation trends and recommend optimal maintenance intervals.

5. The Strategic Synergy of the Three Dimensions

Let’s summarize the essence:

Preventive maintenance ensures compliance and routine stability.

Predictive maintenance transforms maintenance from reactive to data-driven.

Proactive maintenance upgrades the system’s DNA to eliminate root causes.

When these three are layered systematically, the result is not only fewer breakdowns but a fundamentally smarter maintenance culture.

6. A Realistic Roadmap for Industrial Plants

| Phase | Focus | Key Deliverables |

|---|---|---|

| Phase 1 | Preventive foundation | Standard maintenance plan, time-based work orders |

| Phase 2 | Predictive integration | AMS setup, sensor data collection, trend dashboards |

| Phase 3 | Proactive transformation | RCA program, design feedback, asset renewal planning |

The transition usually spans 2–3 years. By Phase 3, maintenance evolves from a cost center into a value-creation process, aligning perfectly with digital transformation and ESG goals.

7. Conclusion

“Turn preventive maintenance into a mandatory habit, predictive maintenance into a data exercise, and proactive maintenance into a design standard—then your instruments will run with low cost and high reliability throughout their entire lifecycle.”

In the era of smart manufacturing, maintenance is no longer just about fixing what’s broken. It’s about designing reliability, predicting failures, and engineering resilience.