Introduction

Guided Wave Radar (GWR) transmitters rely on waveguides to direct the propagation of electromagnetic pulses into the measured medium. The choice of waveguide type has a significant impact on signal quality, measurement accuracy, installation feasibility, and maintenance effort.

This document introduces the three common waveguide types—rigid rod, flexible cable, and coaxial tube—and provides selection guidelines for different process conditions.

1. Waveguide Types and Characteristics

1.1 Rigid Rod Type

Structure: Solid metal rod (commonly 316L stainless steel).

Application: Best for low-viscosity, non-sticky media such as water, solvents, and light chemicals.

Performance:

High accuracy (±2 mm).

Limited probe length (≤6 m).

Limitations: Prone to buildup from crystallization or sticky deposits, which can attenuate signals.

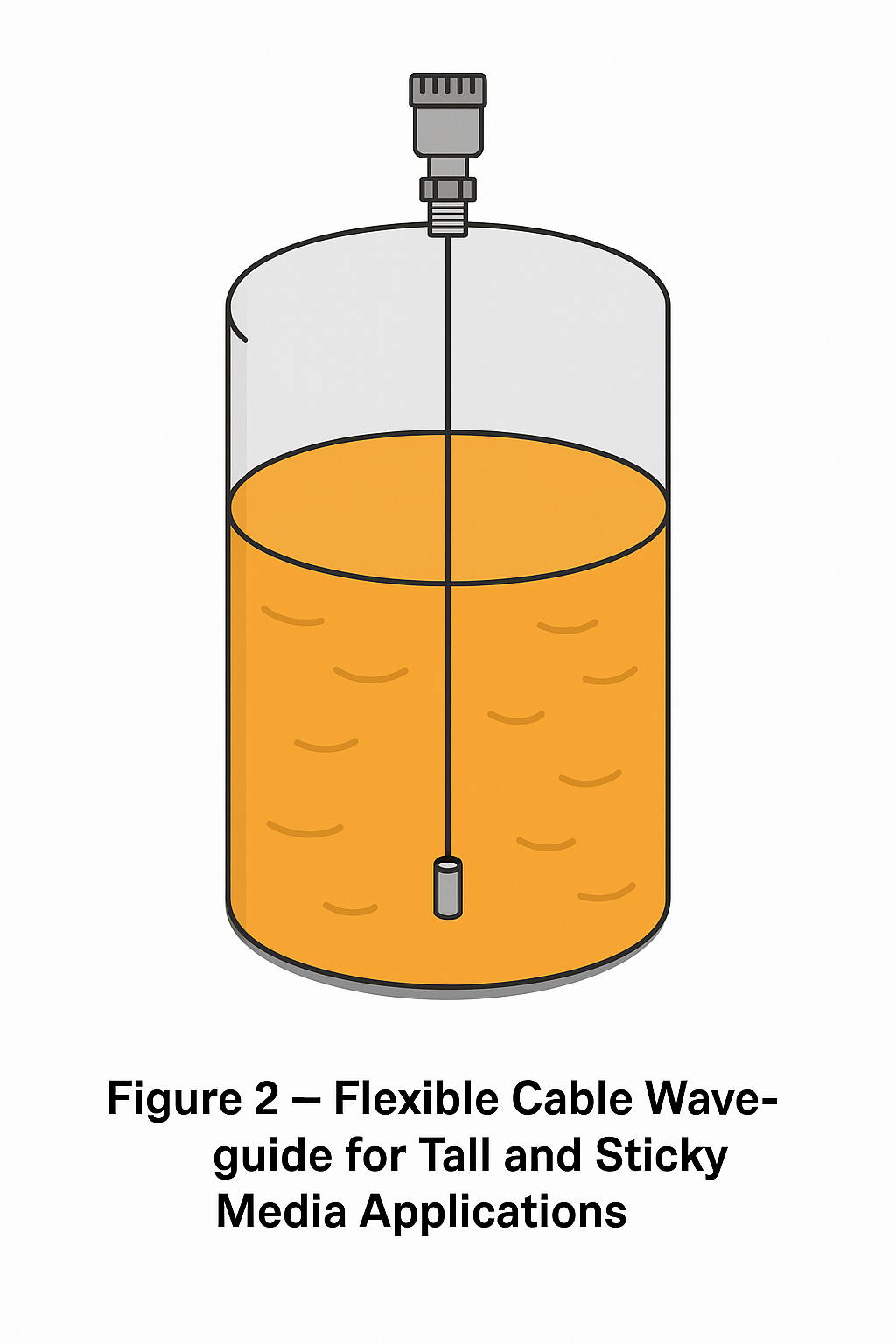

1.2 Flexible Cable Type

Structure: Stainless steel rope with a central conductor; available in single-cable or dual-cable design.

Application: Suitable for high-viscosity liquids (e.g., syrup, asphalt) and tall storage tanks.

Performance:

Measuring range up to 30 m.

Adapts well to irregular or narrow vessels.

Limitations: Cable may sway in strong agitation, introducing measurement noise.

1.3 Coaxial Tube Type

Structure: Inner conductor surrounded by an outer tube, forming a coaxial transmission path.

Application: Offers strongest immunity to foam, vapor, and turbulence, making it ideal for fermentation tanks, foamy liquids, and vapor-rich environments.

Performance:

High measurement stability.

Minimal signal loss even under harsh conditions.

Limitations:

Higher cost.

Requires more installation space.

2. Selection Guidelines

When selecting the proper waveguide, consider the following:

Medium properties

Low viscosity, clean liquids → Rigid rod

High viscosity or long measurement range → Flexible cable

Foam, vapor, strong interference → Coaxial tube

Tank geometry

Narrow or tall tanks → Flexible cable preferred

Wide, short tanks → Rod or coaxial suitable

Process conditions

Strong agitation → Avoid single-cable type, use dual-cable or coaxial

High hygiene requirement (e.g., food, beverage) → Coaxial recommended

📌 Table 1 — Comparison of Guided Wave Radar Waveguide Types

| Parameter | Rigid Rod | Flexible Cable | Coaxial Tube |

|---|---|---|---|

| Typical Range | ≤ 6 m | Up to 30 m | ≤ 6 m |

| Accuracy | ±2 mm | ±5 mm | ±2 mm |

| Suitable Media | Clean, non-sticky | Sticky, viscous | Foamy, vapor-rich |

| Installation Space | Low | Flexible | High |

| Cost Level | Low | Medium | High |

| Agitation Tolerance | Moderate | Limited (may sway) | Excellent |

3. Practical Recommendations

For chemical storage tanks with solvents → choose rigid rod for simplicity and accuracy.

For syrup or asphalt storage in tall silos → use flexible cable to handle viscosity and large range.

For beer fermentation tanks → select coaxial tube to eliminate foam and vapor interference.

Conclusion

The correct choice of waveguide directly influences the reliability, accuracy, and lifecycle cost of guided wave radar level transmitters. By carefully evaluating medium characteristics, process conditions, and installation environment, engineers can optimize both measurement performance and long-term maintenance.