1. Introduction

Threads play a critical role in connection, sealing, and power transmission across mechanical manufacturing, piping systems, and equipment maintenance. Due to differences in standards, thread profiles, and application environments, engineers must carefully select the appropriate thread type.

This document provides a systematic comparison of NPT, PT (BSPT), G (BSPP), TR, S, M, ZG, and RC threads, highlighting their structure, sealing capability, and typical applications.

2. Thread Types

2.1 NPT — American National Pipe Taper Thread

Standard: ASME B1.20.1

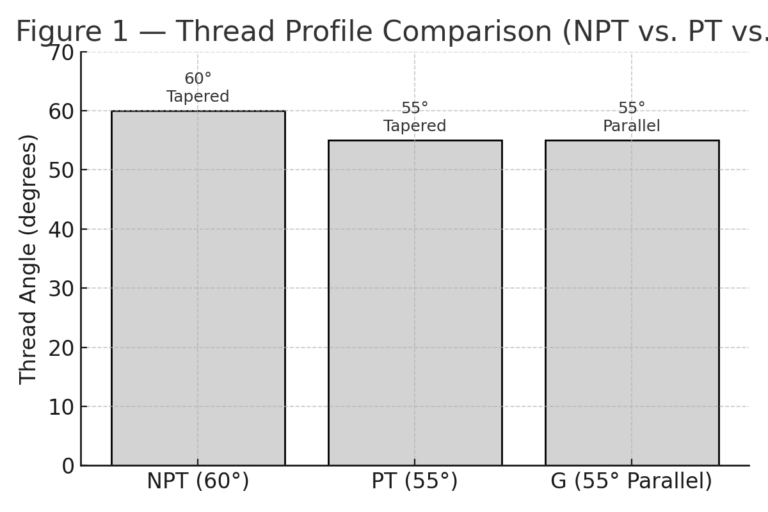

Thread Angle: 60°

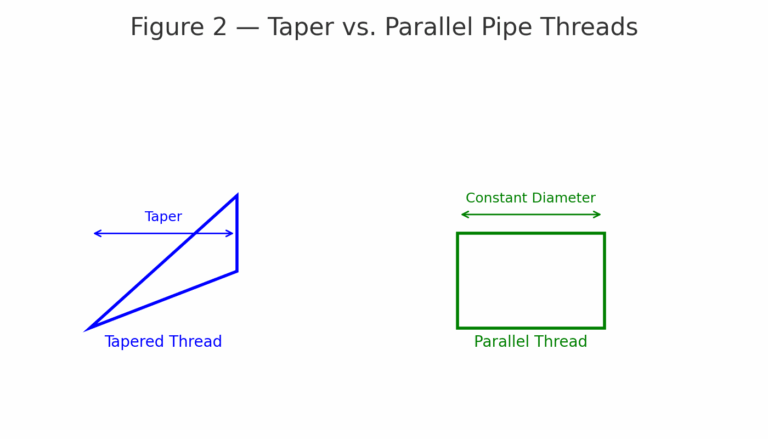

Structure: 1:16 taper, metal-to-metal sealing by interference fit

Applications: Widely used in oil, gas, and fluid pipelines in North America

Key Feature: High sealing reliability, suitable for high-pressure conditions

2.2 PT (BSPT) — British Standard Pipe Taper Thread

Standard: ISO 7-1 / JIS B 0203

Thread Angle: 55°

Structure: 1:16 taper, sealing by interference

Applications: Common in water, air, and low-to-medium pressure pipelines in Europe and Asia

Comparison with NPT: Similar sealing principle, but different thread angle → not interchangeable

2.3 G (BSPP) — British Standard Pipe Parallel Thread

Standard: ISO 228-1

Thread Angle: 55°

Structure: Parallel thread, requires sealing material (gasket, O-ring)

Applications: Building water supply, HVAC, fire protection systems

Key Feature: High universality, but sealing depends on auxiliary materials

2.4 TR — Trapezoidal Thread

Standard: ISO 2901, 2902, 2903

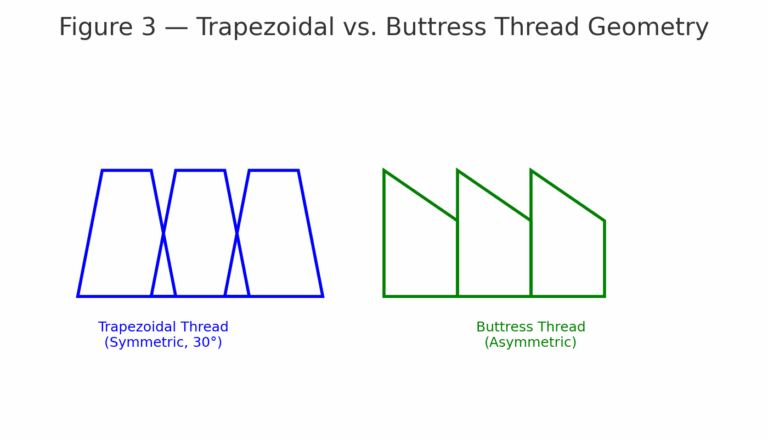

Thread Angle: 30° (sometimes 29°)

Structure: Symmetrical trapezoid, high load-bearing capacity, low friction

Applications: Machine tool lead screws, jacks, heavy-duty transmission

Key Feature: Designed for power transmission, not sealing

2.5 S — Buttress (Saw-Tooth) Thread

Standard: ISO 2903

Profile: Asymmetrical, one flank vertical, one inclined

Applications: Hydraulic presses, jacks, structures with one-directional loads

Key Feature: Optimized for unidirectional force transmission

2.6 M — Metric ISO Thread

Standard: ISO 68-1 / ISO 261

Thread Angle: 60°

Structure: Triangular profile, straight thread

Applications: General mechanical fastening, the most widely used thread type worldwide

Key Feature: Highly standardized, suitable for universal mechanical connections

2.7 ZG — Obsolete Chinese Pipe Taper Thread

Standard: GB 7306 (old standard, replaced by ISO 7/1 RC/RP)

Thread Angle: 55°

Note: Used in legacy equipment, gradually phased out

2.8 RC — ISO Tapered Internal Pipe Thread

Standard: ISO 7-1 (equivalent to BSPT internal)

Thread Angle: 55°

Structure: Tapered internal thread, sealing with matching external thread

Applications: Building, chemical, and mechanical low-to-medium pressure systems

Key Feature: Reliable sealing, widely adopted in international projects

3. Comparison Table

| Thread Type | Angle | Shape | Sealing Method | Typical Applications |

|---|---|---|---|---|

| NPT | 60° | Taper | Self-sealing | Oil & gas pipelines (North America) |

| PT (BSPT) | 55° | Taper | Self-sealing | Water, air pipelines (Europe, Asia) |

| G (BSPP) | 55° | Parallel | Requires gasket/O-ring | Water supply, HVAC |

| TR | 30° | Trapezoidal | Non-sealing | Machine tools, jacks |

| S | Asymmetric | Buttress | Non-sealing | Presses, one-way load |

| M | 60° | Metric ISO | Non-sealing | General fasteners |

| ZG | 55° | Taper | Self-sealing | Legacy Chinese standard |

| RC | 55° | Taper | Self-sealing | Low-medium pressure pipelines |

4. Engineering Selection Guidelines

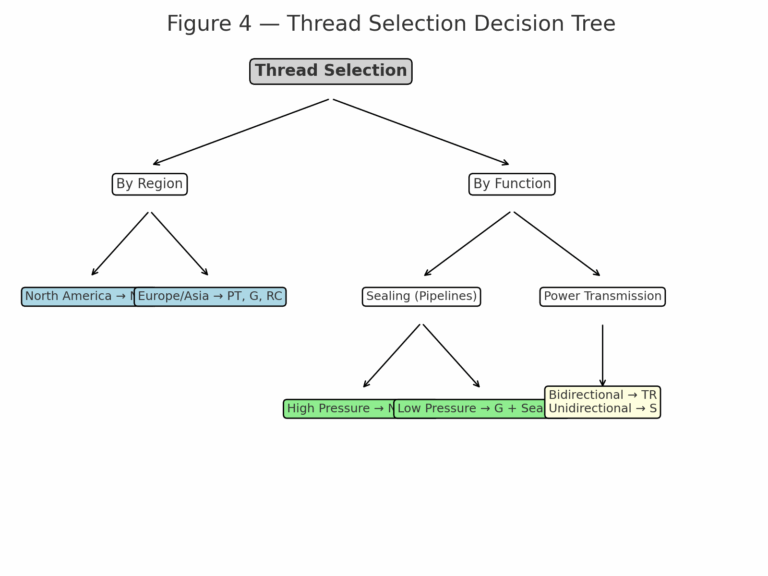

By Region:

North America → NPT

Europe & Asia → PT, G, RC

By Pressure & Medium:

High pressure & hazardous fluids → NPT, RC

Low pressure water/air → G with sealing material

By Mechanical Function:

Power transmission → TR (bidirectional), S (unidirectional)

5. Conclusion

Different thread types vary in angle, sealing performance, and applicable scenarios. Understanding these differences ensures pipeline sealing reliability, efficient power transmission, and safe equipment operation.

In practice, engineers should consider regional standards, medium characteristics, working pressure, and load type to select the most appropriate thread type.