1. Why Redundancy Is Essential

Storage tanks usually contain hazardous media such as oil, acids/alkalis, liquid chlorine, or liquefied hydrocarbons. Any leakage can lead to catastrophic accidents.

Therefore, regulations mandate redundant level measurement systems:

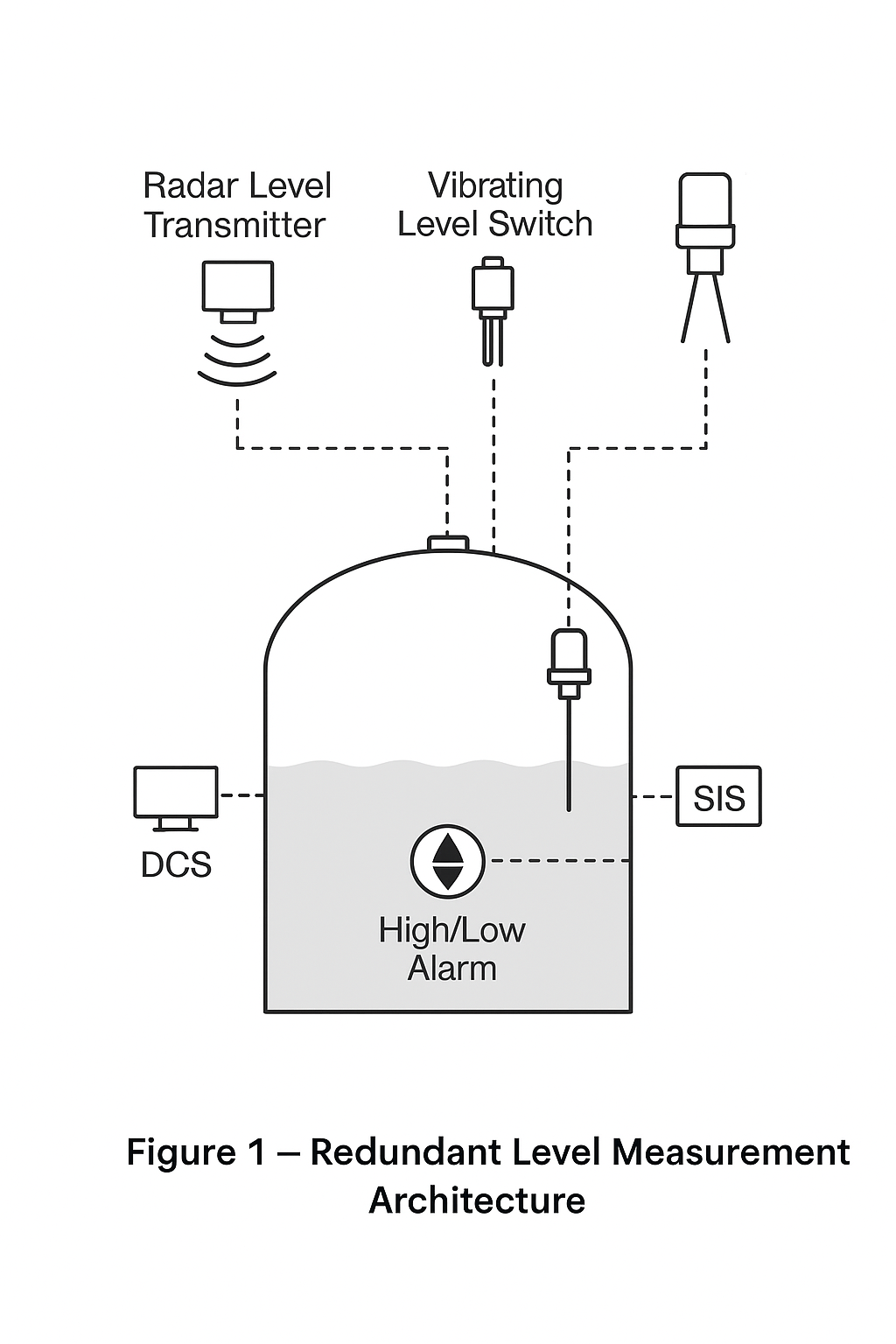

At least two instruments based on different principles (e.g., radar + vibrating level switch) must be installed as backups.

Independent alarm and interlock signals must be transmitted separately to ensure that emergency shut-off valves are triggered immediately.

👉 In short: level measurement must not only “measure” but also measure accurately, alarm quickly, and act reliably.

2. Key Requirements from Major Standards

SH/T 3007-2014: Flammable and toxic storage tanks must be equipped with two sets of level meters based on different principles, installed independently.

SH/T 3184-2017: Custody-transfer tanks must have dual level meters, with one used for alarming and the other for measurement.

GB/T 50493-2019: Level measurement systems must be linked with combustible/toxic gas detection systems.

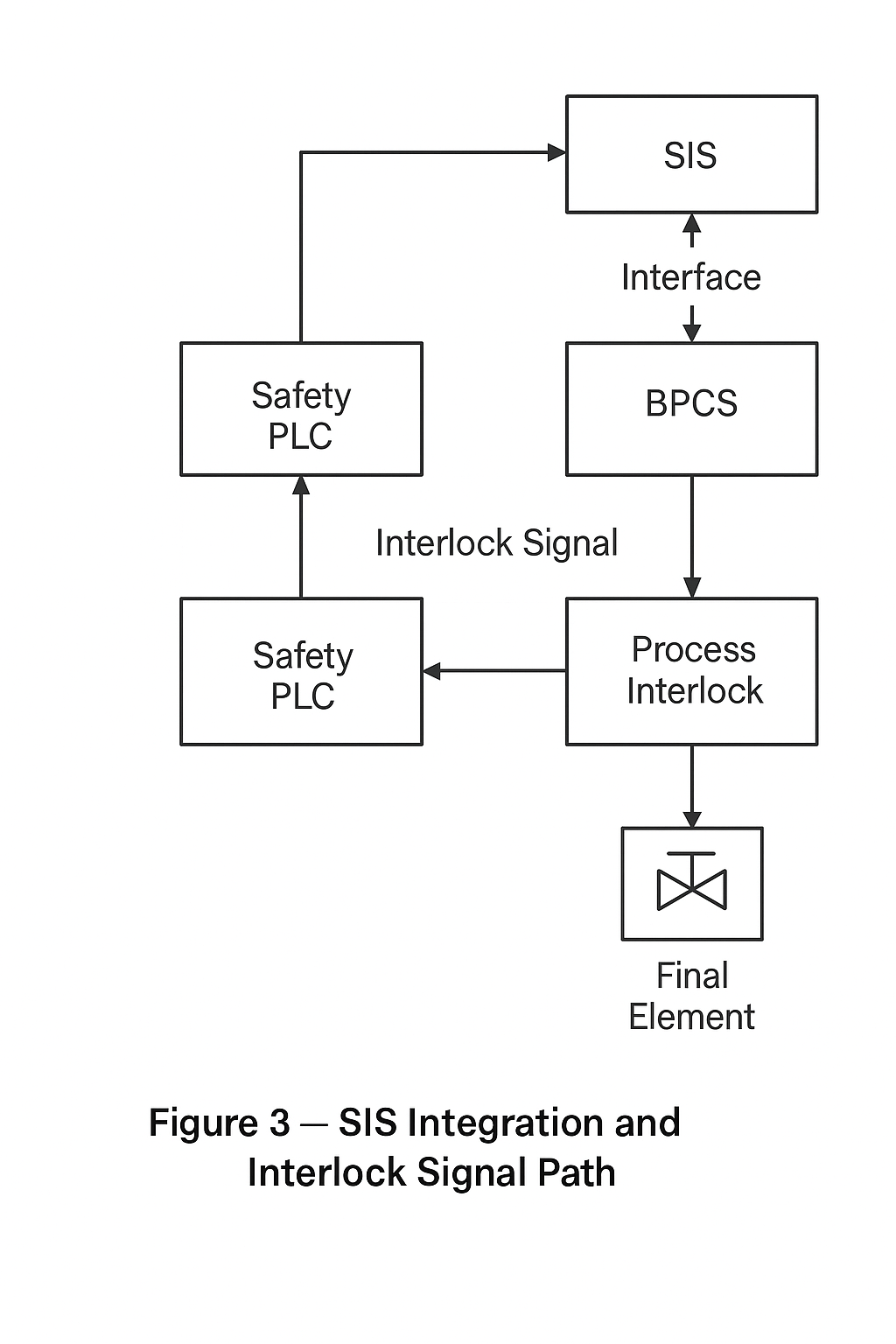

GB 50160-2008: Large storage tank level measurement must be integrated into the Safety Instrumented System (SIS) and meet SIL2 or SIL3 requirements.

GB 17681-2024: Requirements vary by tank type:

Atmospheric tanks: Two continuous devices, or one continuous + two point switches.

Pressure tanks: Two continuous devices + one high-high switch.

Cryogenic tanks: At least three independent devices.

Table 1 — Level Measurement Requirements by Tank Type

| Tank Type | Minimum Continuous Measurement Devices | Point Level Switches | Special Requirements |

|---|---|---|---|

| Atmospheric Tank | 2 continuous devices, or 1 continuous + 2 point switches | 2 (if only one continuous device is used) | Must allow for redundancy; suitable for oil, general chemicals |

| Pressure Tank | 2 continuous devices | 1 high-high level switch | Interlock signals must connect to SIS; SIL2/SIL3 compliance required |

| Cryogenic Tank | At least 3 continuous devices | Recommended high/low switches for safety | Must consider low-temperature reliability and insulation design |

| Toxic/Flammable Media Tanks | 2 devices based on different principles (e.g., radar + servo) | Independent alarm and interlock paths | Glass tube gauges prohibited; signals must be sent to both DCS and SIS |

| Custody-Transfer Tanks | Dual devices (1 for measurement, 1 for alarm) | Optional, based on HAZOP | Accuracy and calibration must comply with SH/T 3184-2017 |

3. Typical Configuration Schemes

Liquefied hydrocarbons, benzene, and other high-risk tanks

Non-contact radar level transmitter + servo gauge + high/low level switches

Signals transmitted simultaneously to both DCS and SIS

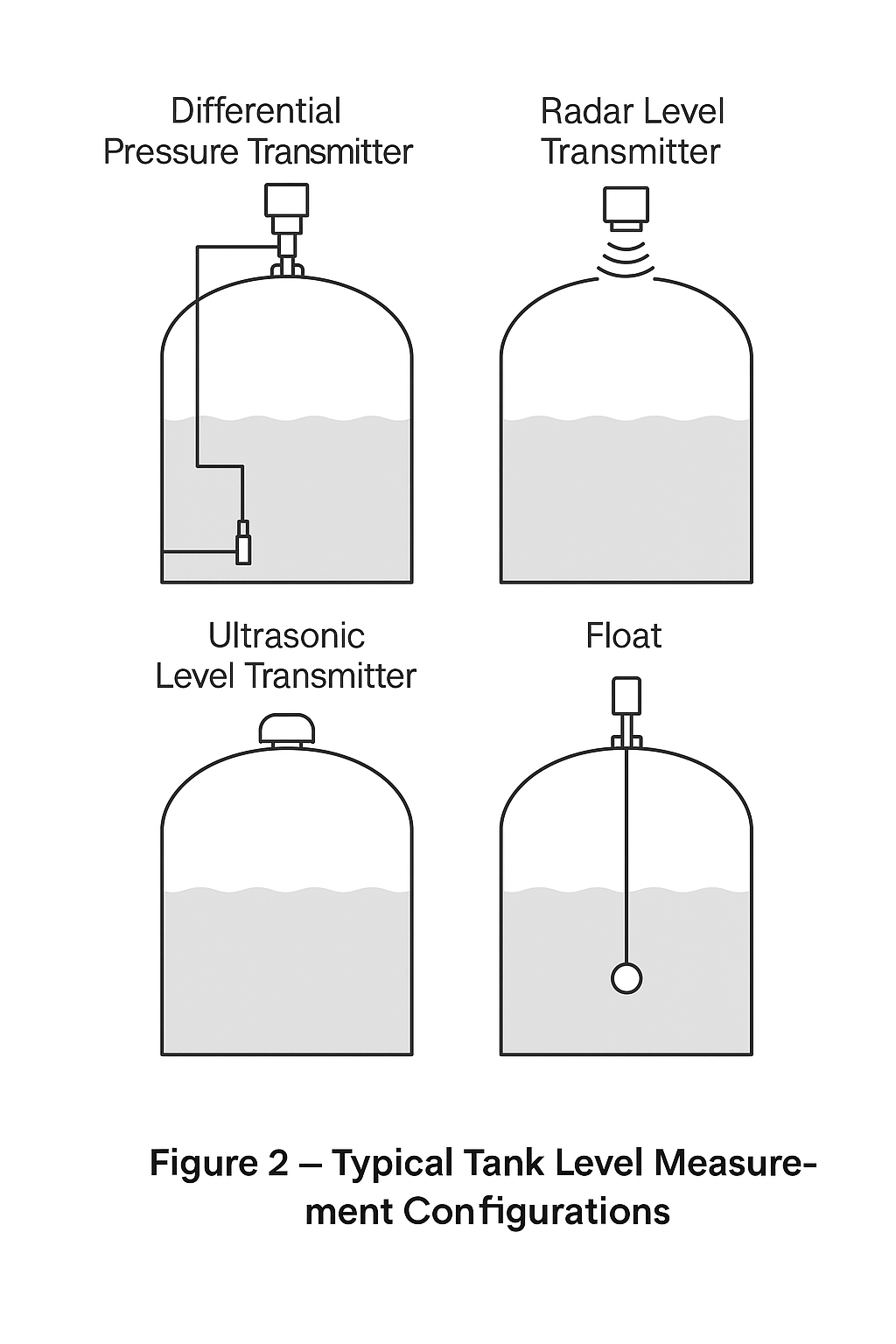

Atmospheric crude oil storage tanks

Guided wave radar + magnetostrictive level transmitter

Periodic manual dip checks for verification

Acid/alkali tanks

Ultrasonic level transmitter + pressure transmitter (liquid head conversion)

Prevents probe damage from corrosion

Liquid chlorine tanks

Local indicator + remote radar level transmitter

Glass tube level gauges are strictly prohibited

4. Critical Implementation Details

Avoid Common-Cause Failures

Instruments must not share the same power supply, signal wiring, or mounting nozzle.

Regular Calibration

Follow JJG 971-2019 standards. Verification must be performed at least once per year by certified agencies.

Documentation and Archiving

HAZOP studies, SIL verifications, and LOPA analyses must be properly archived for future audits and inspections.

5. Conclusion

High-risk scenarios → Dual principles + SIS interlock, complying with SIL2/SIL3.

General storage tanks → At least dual instruments; even if same principle, justification through HAZOP analysis is required.

Special media → Choose a combination of contact and non-contact technologies tailored to chemical properties.

👉 Tank level measurement is not merely selecting an instrument—it is the safety lifeline that ensures compliance and prevents accidents.

Table 2 — Compliance Checklist for Tank Level Measurement Projects

| Category | Checklist Items | Compliance Reference |

|---|---|---|

| Redundancy | At least two level instruments installed; preferably different measurement principles | SH/T 3007-2014, GB 17681-2024 |

| Independent Signal Paths | Alarm and interlock signals transmitted through separate wiring and channels | GB/T 50493-2019 |

| Safety Integration | High/High alarms connected to SIS, meeting SIL2 or SIL3 requirements | GB 50160-2008 |

| Tank Type-Specific Rules | Requirements vary for atmospheric, pressure, and cryogenic tanks (see Table 1) | GB 17681-2024 |

| Prohibited Devices | Glass tube level gauges not allowed in toxic or flammable media tanks | Safety regulations (MEE directives) |

| Calibration & Testing | Annual verification per JJG 971-2019; records maintained | JJG 971-2019 |

| Documentation | HAZOP, SIL verification, and LOPA analysis reports archived for audits | Industry best practices |

| Common-Cause Failure | Instruments must not share power supply, cabling, or mounting nozzle | Engineering practice guidelines |

| Emergency Shutdown (ESD) | SIS output linked to final element (e.g., ESD valve) with periodic function testing | IEC 61511, GB standards |