1. Introduction

In industrial electrical control systems, the concepts of self-locking, interlocking, and mutual locking are fundamental. Although similar in terminology, each has distinct logic, application, and purpose. This document provides a structured comparison of these three control methods, with definitions, working principles, typical applications, and schematic diagrams.

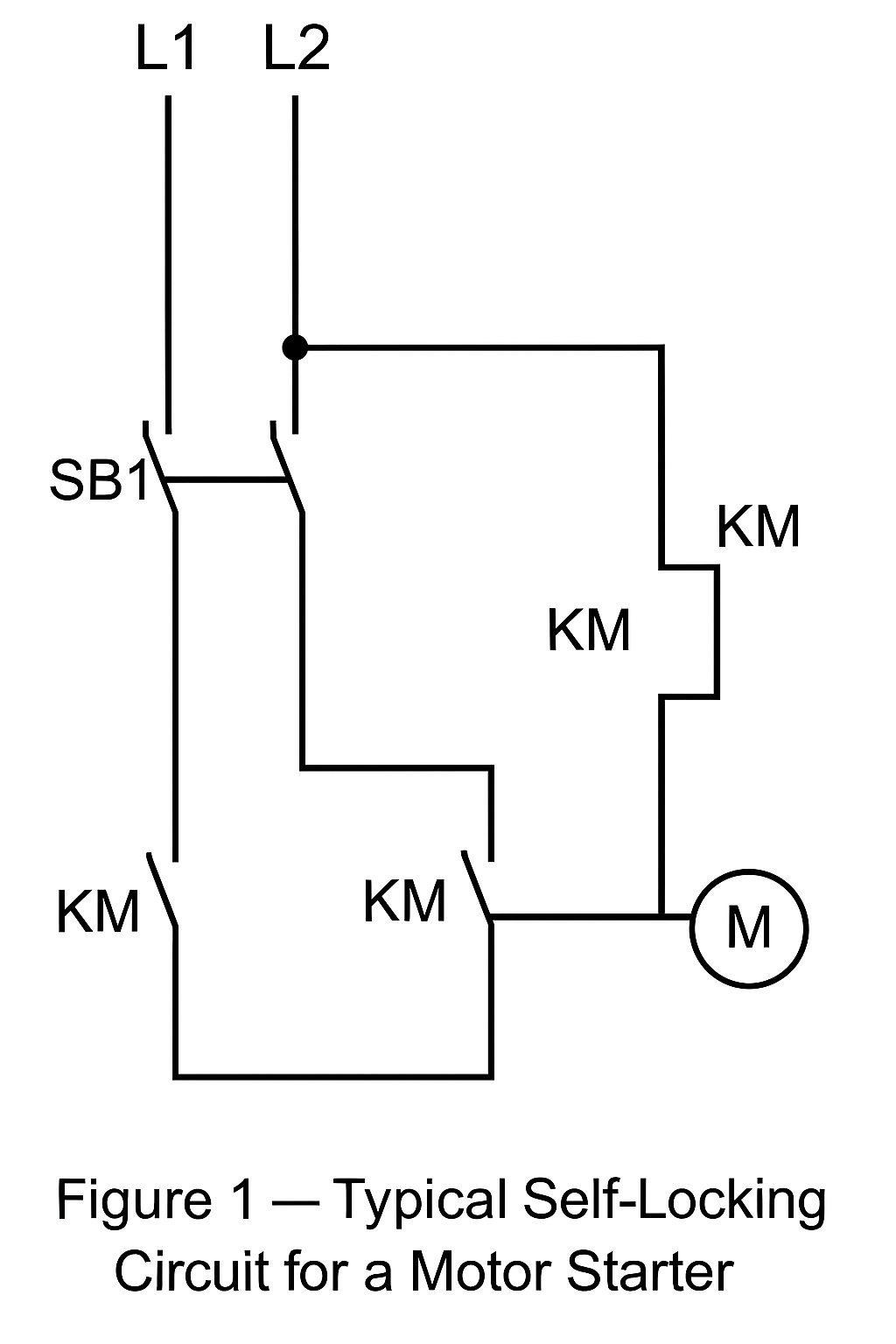

2. Self-Locking (Hold-On Circuit)

2.1 Definition

Self-locking refers to the ability of a control element (such as a relay or contactor) to maintain its energized state even after the initiating signal disappears.

2.2 Working Principle

A normally open (NO) auxiliary contact of the relay or contactor is wired in parallel with the start button. Once the button is pressed, the contactor energizes and its NO auxiliary contact closes, forming a holding circuit. This maintains the energized state even after the button is released.

2.3 Application

Motor start/stop circuits

Processes requiring continuous operation after a single trigger

2.4 Advantages

Simplifies operator action (no need to hold the button continuously)

Ensures stable equipment operation

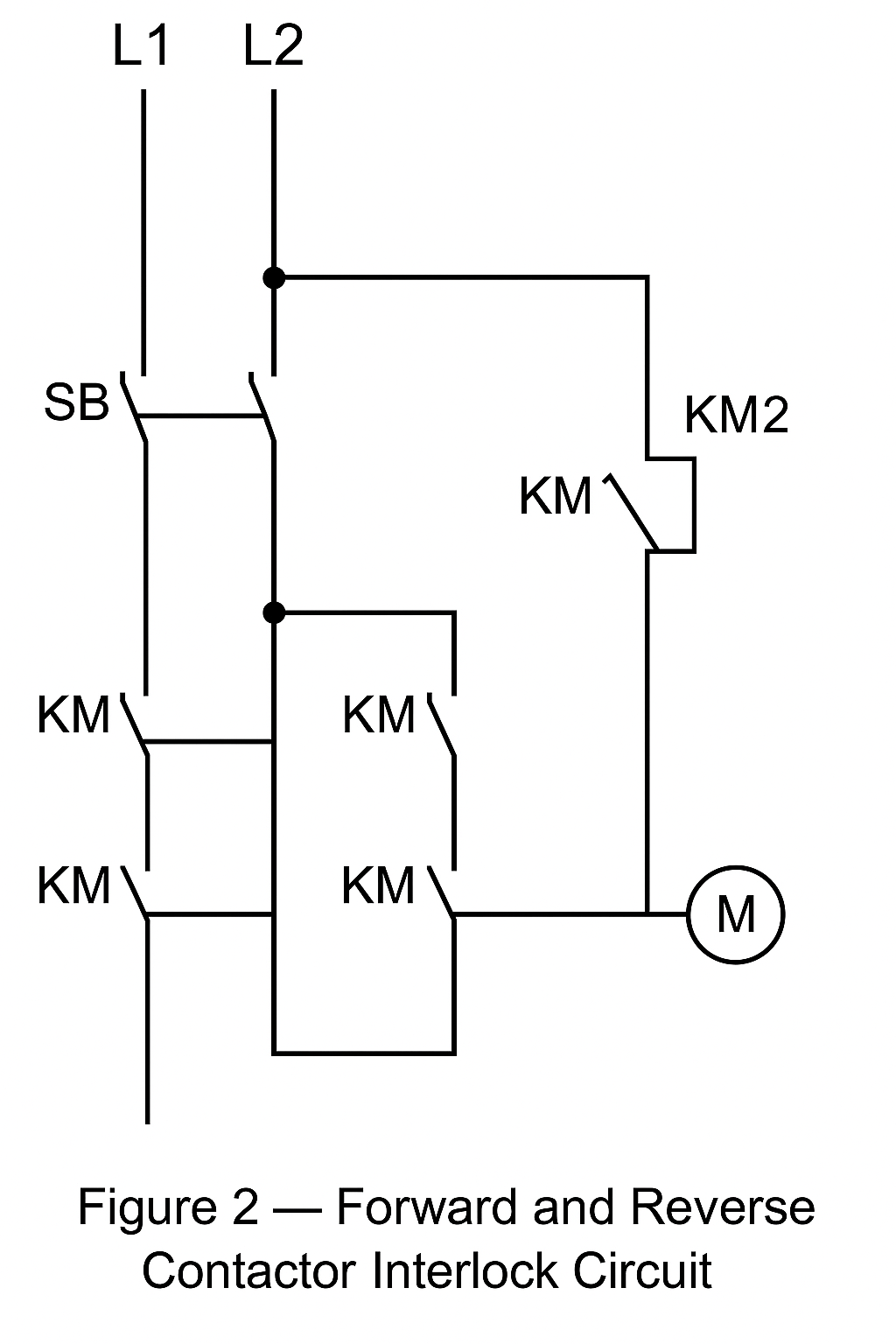

3. Interlocking

3.1 Definition

Interlocking is a logic relationship that prevents two or more devices from operating simultaneously, avoiding conflicts or unsafe conditions.

3.2 Working Principle

When one device is energized, the interlock contacts (normally closed) are opened in the control loop of the other device, preventing it from being energized at the same time.

3.3 Application

Forward/reverse motor control

Sequential control of multiple motors (start/stop order)

Safety protection where mutual exclusion is required

3.4 Advantages

Prevents short circuits and equipment conflicts

Improves safety and system reliability

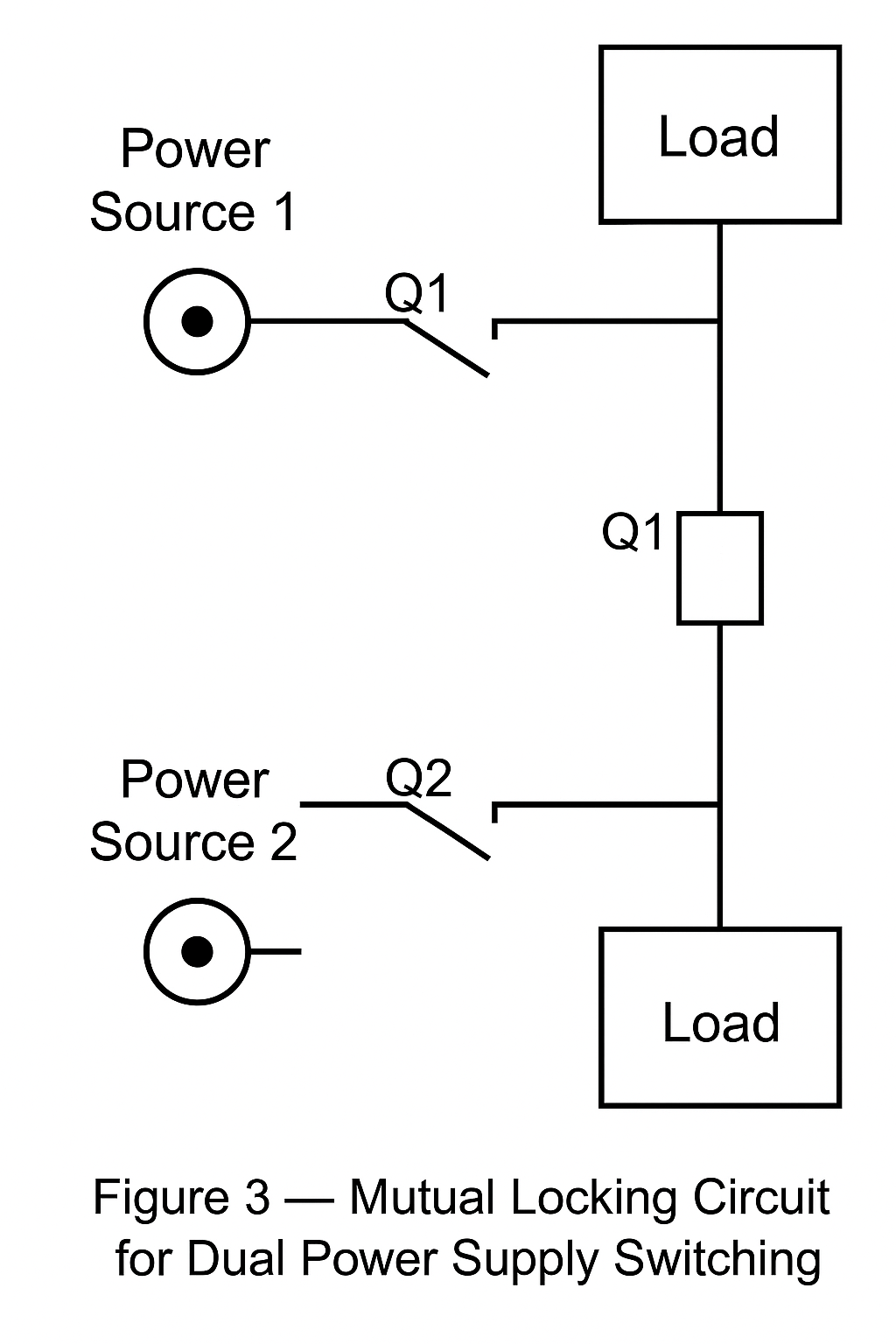

4. Mutual Locking

4.1 Definition

Mutual locking refers to a condition where two or more devices restrict each other’s operation in such a way that one can only run if the other is in a defined state. It emphasizes dependency and coordination, not just exclusion.

4.2 Working Principle

Auxiliary contacts of each contactor are wired in series with the control circuit of the other. When one contactor energizes, it blocks the other’s control path, ensuring coordinated operation.

4.3 Application

Dual power supply transfer switches (only one source can be active at a time)

Coordinated machine operation where dependency is required

4.4 Advantages

Ensures synchronization between devices

Prevents unsafe independent operation

5. Comparative Summary

Table 1 — Comparison of Self-Locking, Interlocking, and Mutual Locking

| Mechanism | Definition | Main Function | Typical Application |

|---|---|---|---|

| Self-Locking | Holds device state after trigger | Simplifies control, maintains operation | Motor start/stop control |

| Interlocking | Prevents simultaneous operation | Avoids conflicts, enhances safety | Forward/reverse motor circuits |

| Mutual Locking | Devices restrict each other’s operation | Ensures dependency and coordination | Dual power supply switching |

6. Conclusion

Self-locking, interlocking, and mutual locking are core principles in electrical circuit design.

Self-locking simplifies operator control.

Interlocking ensures safety by preventing conflicts.

Mutual locking provides coordination in systems requiring dependency.

Understanding and applying these principles correctly is essential for safe and efficient electrical control system design.