Abstract

RS485 is frequently misunderstood as a “communication protocol,” whereas in reality, it is a physical layer interface standard. This article explains the fundamentals of RS485, highlights common misconceptions, compares it with application protocols such as Modbus RTU, and provides practical engineering guidelines for installation, wiring, and troubleshooting.

1. What Exactly is RS485?

RS485 is not a protocol. It is a recommended standard (RS) defining the physical layer electrical characteristics for differential signaling.

Its close relatives include RS232 (single-ended) and RS422 (differential, point-to-point).

Among them, RS485 has become the most widely used in industrial automation due to:

Strong noise immunity and signal stability

Long-distance capability (up to 1200 m under ideal conditions)

Multi-drop support (one master with multiple slave devices)

2. Wiring Considerations

The most reliable wiring method is the daisy chain (bus topology), where devices are connected in series along one cable.

Recommended cable: shielded twisted pair (RVSP2×0.5), 120 Ω characteristic impedance

For cable lengths >100 m, add 120 Ω termination resistors at both ends

Avoid star topology (branch connections), as it causes reflection and troubleshooting difficulties

3. Device Capacity on One Bus

Theoretical limits vary depending on transceiver IC design (32, 128, or even 256 nodes).

However, for stable performance:

Keep device count ≤30 per bus

For larger systems, split into multiple buses (e.g., 100 devices → 4 buses with 25 each)

Table 1 — RS485 Bus Capacity vs. Recommended Practice

| Bus Capacity (Theoretical) | Typical Driver Technology | Practical Limit (Recommended) | Engineering Practice |

|---|---|---|---|

| 32 nodes (1 Unit Load, UL) | Early-generation RS485 transceivers | ≤ 30 devices per bus | Use short cable lengths, ensure proper termination |

| 128 nodes (1/4 UL) | Modern low-load drivers | ≤ 60–80 devices per bus | Split into multiple segments when exceeding 50 devices |

| 256 nodes (1/8 UL) | Advanced low-load drivers | ≤ 120–150 devices per bus | Add repeaters, isolate groups for easier troubleshooting |

| >256 nodes (theoretical) | Specialized hub/repeater architectures | Not recommended on a single bus | Use RS485 network segmentation, gateways, or fieldbus alternatives |

📌 Key Notes:

Theoretical capacity assumes ideal cable, perfect termination, and uniform devices.

In real-world industrial environments, signal integrity and troubleshooting become major concerns once bus loading exceeds ~30 nodes.

For systems above 60 devices, segmentation (multi-bus + repeaters) is strongly recommended for reliability and maintainability.

4. Transmission Distance

Ideal conditions: Up to 1200 m at low baud rate (9600 bps, single device, high-quality cable)

Practical field conditions: Cable quality, multiple nodes, and converter quality reduce distance

Engineering rules of thumb:

100 m → Add termination resistors

1000 m → Use repeaters

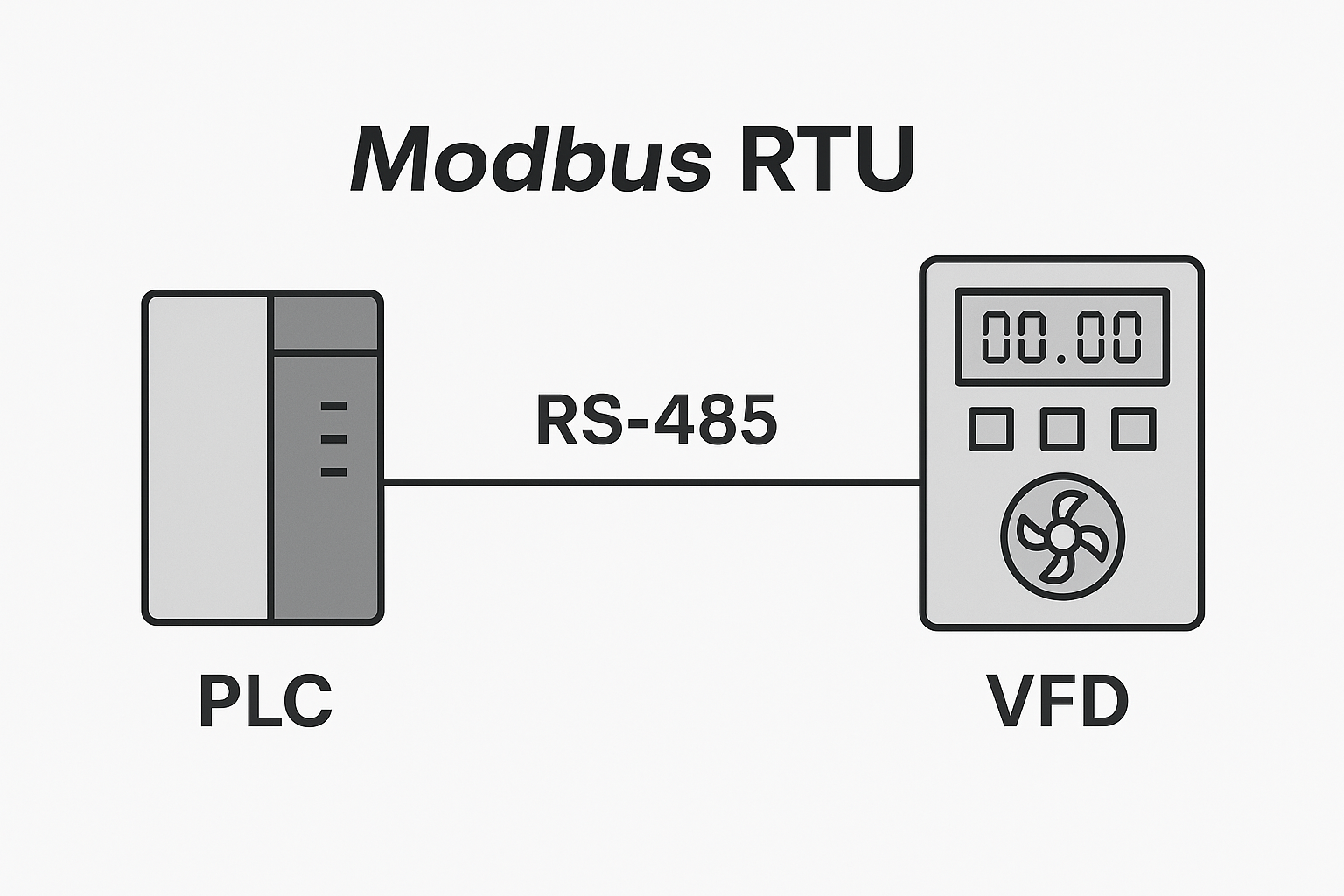

5. RS485 ≠ Modbus RTU

A frequent misconception is equating RS485 with Modbus.

RS485: Physical layer standard (“the road”)

Modbus RTU: Application layer protocol (“the vehicle”)

RS485 can carry Modbus, but also many other protocols. They exist at different OSI layers.

Table 2 — RS485 vs. Modbus RTU in the OSI Model

| OSI Layer | RS485 (Physical Layer Standard) | Modbus RTU (Application Protocol) |

|---|---|---|

| Application Layer | ✗ Not defined | ✓ Defines commands, function codes, and data structure |

| Presentation Layer | ✗ Not applicable | ✓ Encodes data fields into standardized frames |

| Session Layer | ✗ Not applicable | ✓ Defines master–slave interaction and request/response |

| Transport Layer | ✗ Not applicable | ✗ Relies on underlying serial link (no transport abstraction) |

| Network Layer | ✗ Not defined | ✗ Operates directly on serial line, no addressing beyond slave IDs |

| Data Link Layer | ✗ Not defined | ✓ Defines frame boundaries, error checking (CRC) |

| Physical Layer | ✓ Defines differential signaling, wiring, voltage levels | ✗ Relies on RS485 (or RS232, RS422, TCP/IP as carriers) |

6. Communication Speed: Debunking the “Slow” Myth

Speed depends on:

Data size per frame

Baud rate and hardware conditions

Modbus RTU messages are compact and efficient. The limitation lies in serial communication speed, not the protocol itself. For most industrial applications, typical response times (tens of ms) are more than sufficient.

7. Master-Slave Architecture

The most common setup is one master with multiple slaves on RS485.

Pros: Simple wiring, low cost

Cons: Polling mechanism reduces efficiency, unsuitable for ultra-high-speed demands

This reflects a trade-off: cost-effectiveness vs. performance.

8. Summary

RS485 is a physical layer standard, not a protocol.

Use bus topology (daisy chain), avoid star connections.

Limit devices per bus; split large systems into multiple buses.

For long distances, use termination resistors or repeaters.

Modbus RTU often runs on RS485, but they are not interchangeable concepts.

Communication “slowness” is caused by serial hardware limits, not the Modbus protocol.

Ultimately, the key to successful RS485 system design is choosing the right topology, cable, and device distribution for the application scenario.