Abstract

Thermal automation instruments and chemical automation instruments both belong to the broader category of industrial automation instruments, serving as key enablers for process monitoring and control. While they share a common foundation in principles, functions, and architecture, they also exhibit distinct differences due to variations in process media, application scenarios, and control objectives. This article analyzes their commonalities and differences, and provides guidance for practical selection.

1. Commonalities

1.1 Core Functions

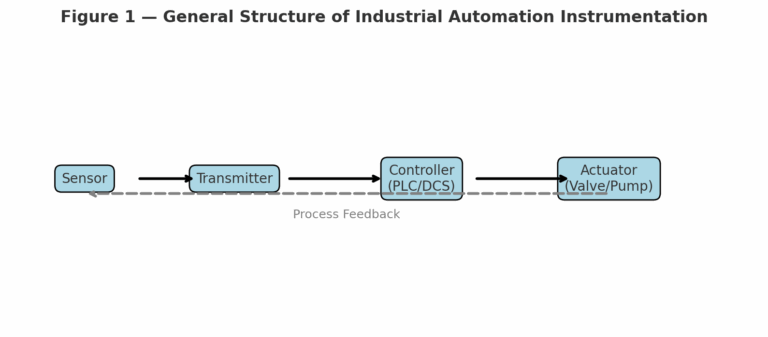

Both types of instruments follow the same logic of monitoring → control → execution. Sensors collect process parameters (e.g., temperature, pressure, flow), transmitters convert them into standard signals (e.g., 4–20 mA, HART protocol), controllers (PLC/DCS) process the signals, and actuators (valves, pumps) adjust the process to form a closed-loop control.

1.2 Basic Components

Detection elements: thermocouples, pressure sensors, flowmeters.

Transmitters: convert physical quantities into electrical signals.

Controllers: PLCs, DCS systems, or SCADA units.

Actuators: control valves, pumps, motors.

Auxiliary devices: display instruments, barriers, surge protectors.

1.3 Shared Control Theories

Both rely on automatic control principles such as PID control algorithms, ensuring process stability and safety.

Examples:

Drum water level control in power plants (thermal).

Reactor temperature control in chemical processes.

1.4 Development Trends

Driven by Industry 4.0, both are evolving towards:

Digitalization and networking (e.g., LoRa, 5G, Ethernet).

Self-diagnosis and predictive maintenance (fault alarms, drift detection).

Industrial Internet integration (SCADA, MES, cloud analytics).

1.5 Safety Requirements

Explosion-proof designs in hazardous areas.

Electromagnetic compatibility (EMC) and lightning protection.

High reliability and redundancy for critical parameters such as boiler furnace pressure or reactor pressure.

2. Differences

2.1 Application Scenarios and Core Equipment

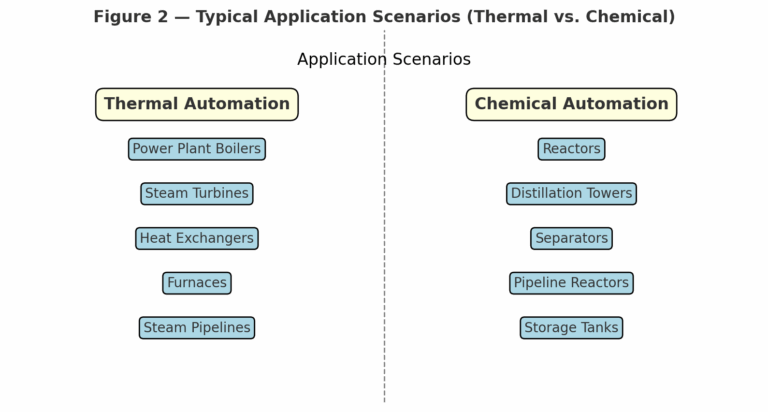

| Dimension | Thermal Automation Instruments | Chemical Automation Instruments |

|---|---|---|

| Core Industries | Power generation, metallurgy, district heating | Petrochemicals, fine chemicals, coal chemicals, pharmaceuticals |

| Key Equipment | Boilers, turbines, heat exchangers, steam lines | Reactors, distillation towers, separators, tanks |

| Core Processes | Heat generation, transfer, and conversion | Chemical reactions, separation, purification |

2.2 Measurement Focus

Thermal instruments:

Temperature: from ambient to >1600 °C.

Pressure: often >10 MPa (superheated steam).

Flow: water, steam, flue gas.

Level: boiler drum, condenser.

Chemical instruments:

Composition analysis: pH, O₂, CO, H₂S, concentration.

Special physical properties: viscosity, density.

Flow and level: often corrosive, toxic, or viscous fluids.

2.3 Influence of Medium Characteristics

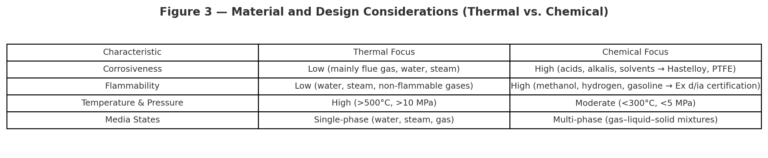

| Characteristic | Thermal Instrument Design Focus | Chemical Instrument Design Focus |

|---|---|---|

| Corrosiveness | Low (mainly flue gas, water, steam) | High (acids, alkalis, solvents → Hastelloy, PTFE) |

| Flammability | Low | High (methanol, hydrogen, gasoline → Ex d/ia certification) |

| Temperature & Pressure | High (>500 °C, >10 MPa) | Moderate (<300 °C, <5 MPa) |

| Media States | Single-phase (water, steam, gas) | Multi-phase (gas–liquid–solid mixtures) |

2.4 Control Objectives

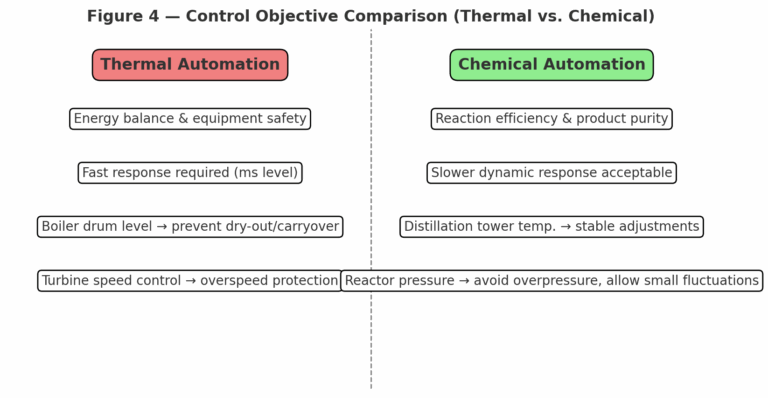

Thermal: focus on energy balance and equipment protection.

Example: millisecond-level response in turbine speed control.

Boiler drum level must be tightly controlled to avoid dry-out or carryover.

Chemical: focus on reaction efficiency and product purity.

Example: distillation tower temperature requires stable and slow adjustments.

Reactors allow slight parameter fluctuations but require anti-overpressure safety.

2.5 Typical Instrument Examples

Temperature:

Thermal → Tungsten-rhenium thermocouples (>1800 °C).

Chemical → Sheathed thermocouples (anti-corrosion), infrared thermometers.

Pressure:

Thermal → High-pressure transmitters (≥30 MPa).

Chemical → Corrosion-resistant diaphragm transmitters (tantalum/PTFE).

Flow:

Thermal → Orifice plates (steam).

Chemical → Electromagnetic flowmeters (corrosive liquids), vortex flowmeters (flammable gases).

Analysis:

Chemical → Online gas chromatographs, pH analyzers.

Thermal → Flue gas analyzers (NOx, SO₂).

3. Conclusion and Application Guidance

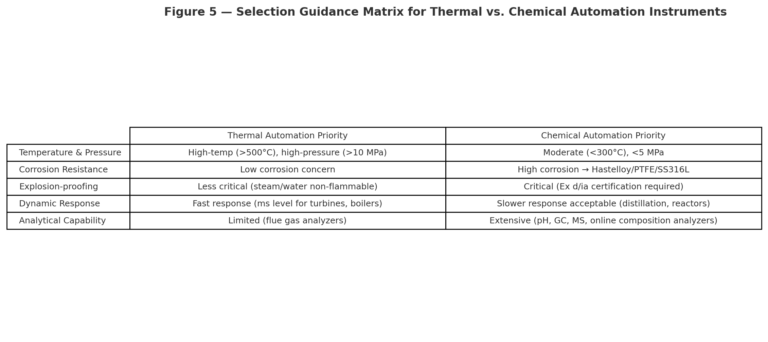

Thermal and chemical automation instruments share a common technical foundation but differ significantly in media handling, parameter emphasis, design requirements, and control objectives.

Practical Guidelines:

Thermal industries: prioritize high-temperature, high-pressure resistance and fast dynamic response.

Chemical industries: prioritize corrosion resistance, explosion-proofing, and advanced online analysis.

Cross-industry trend: both are moving towards intelligent, digital, and networked solutions, blurring traditional distinctions.