1. Introduction

Pipeline purging is a common industrial operation that plays a critical role in ensuring system reliability and safety. It removes impurities such as welding slag, rust, and other debris from pipelines, preventing potential damage to downstream equipment. In applications such as syngas production and compressor systems, effective purging is essential for stable and safe operation.

2. Purpose and Significance of Pipeline Purging

Prevent Equipment Damage

Solid particles left in the pipeline during fabrication or welding can strike and damage critical components such as pistons and valves, leading to unplanned shutdowns. Purging eliminates these risks.Reduce Blockages and Valve Failures

Welding residues and metallic debris may obstruct valve seals, causing sticking or leakage. Purging prevents such failures and ensures smooth operation.Improve System Efficiency and Safety

Clean pipelines allow unobstructed gas flow, improving overall efficiency and reducing the risk of operational accidents.

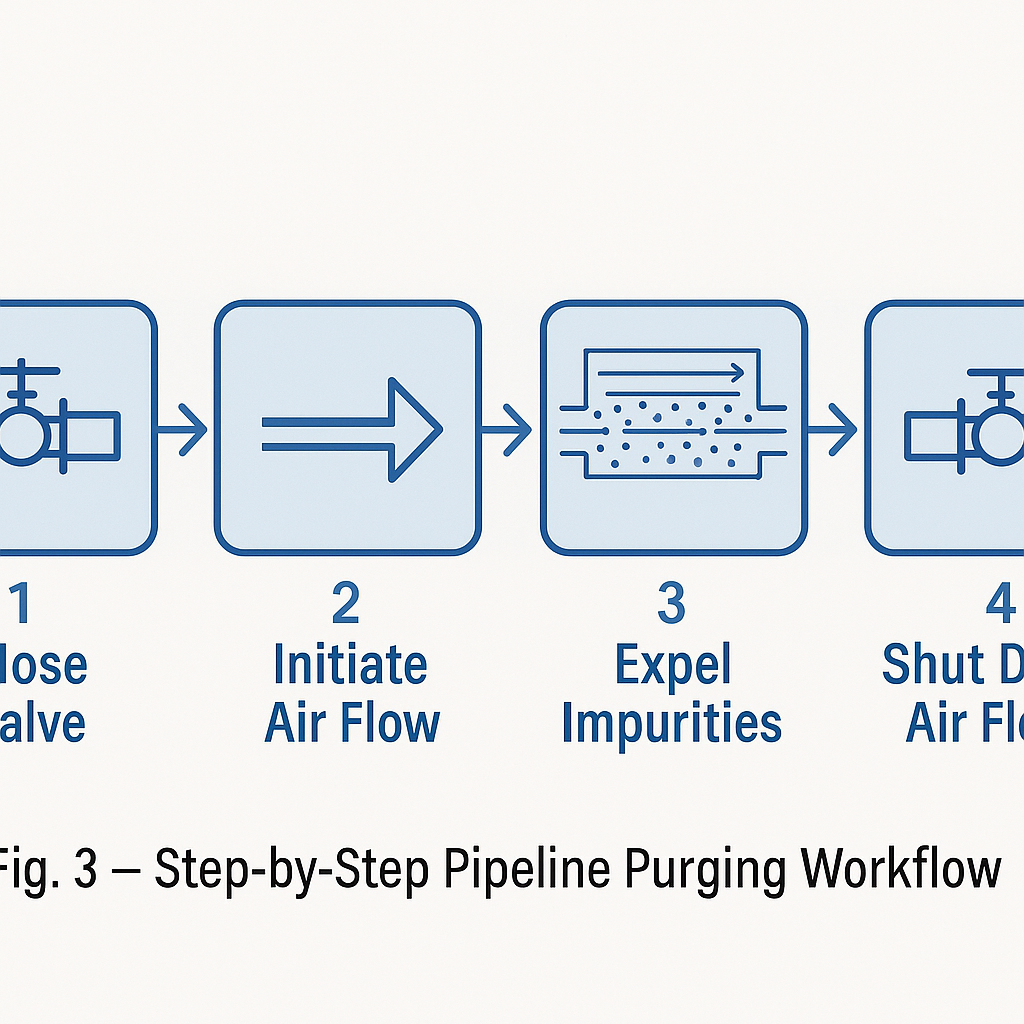

3. Typical Pipeline Purging Procedure

Although purging appears simple, it must be carried out under strict procedures to ensure effectiveness and avoid secondary contamination.

Preparation

Select purging medium (compressed air, nitrogen, or other inert gas).

Verify the integrity of pipelines and ensure sealed outlets.

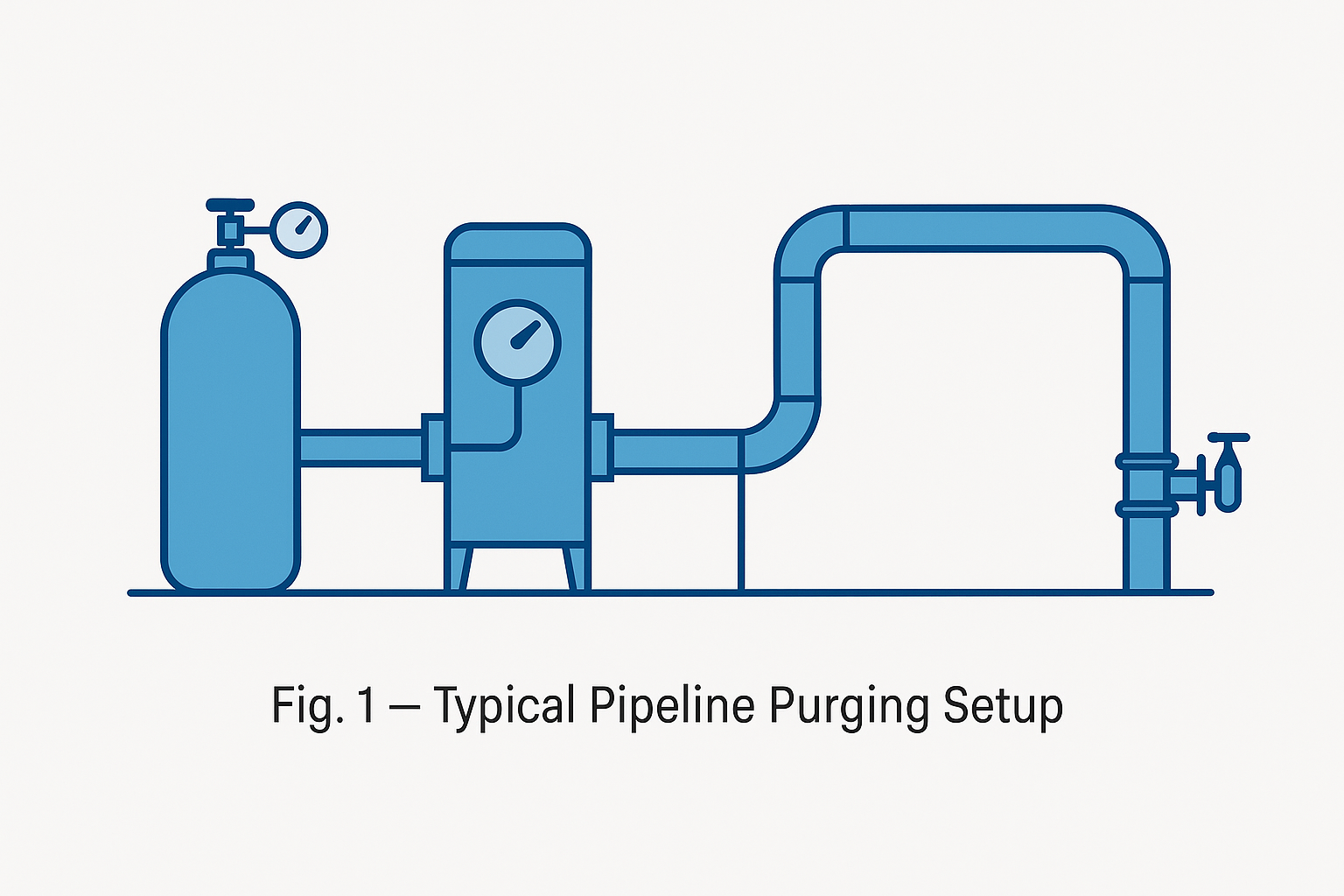

Connection of Purging Equipment

Connect the compressed air or nitrogen source to the pipeline.

Ensure that the pressure and flow rate meet purging requirements.

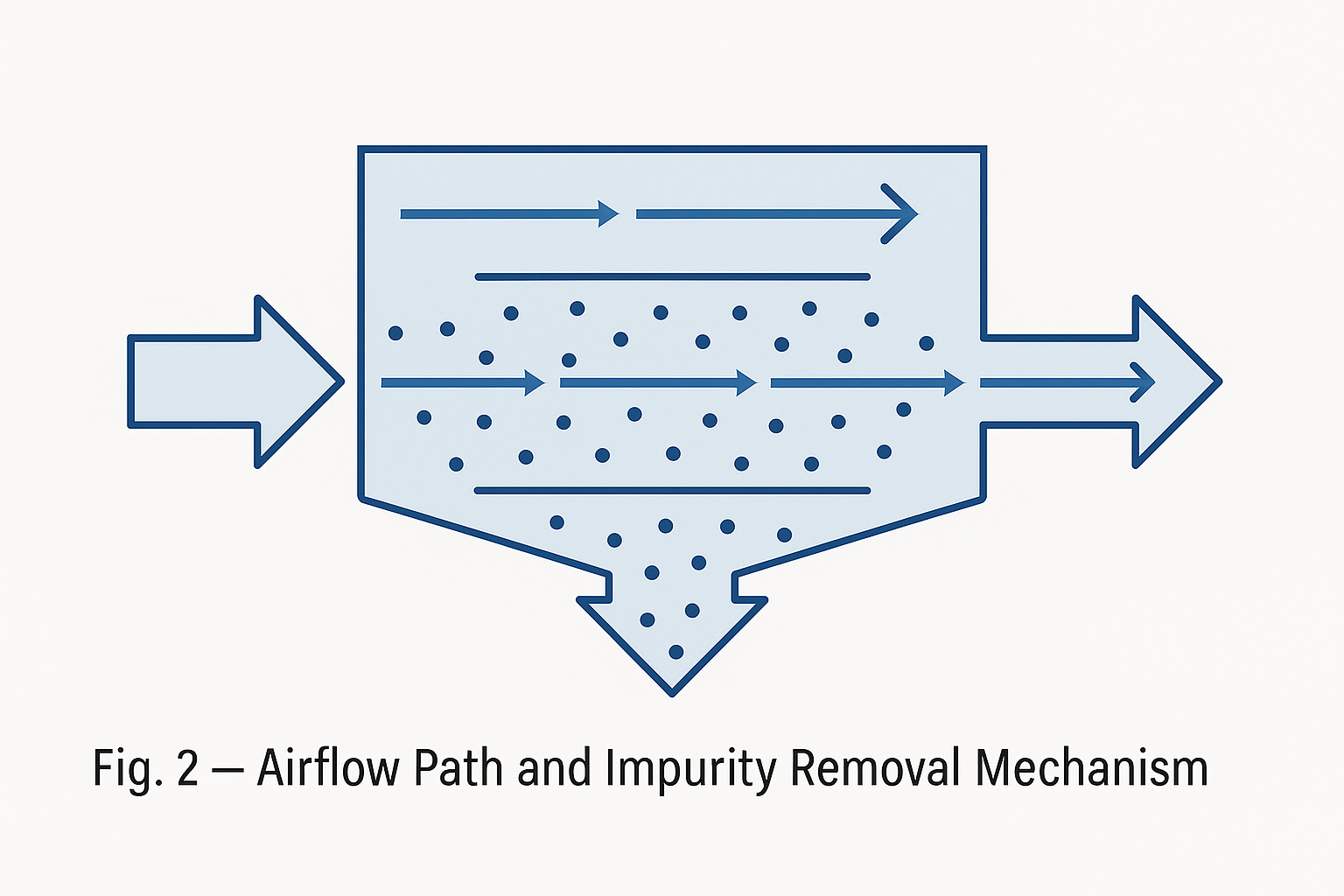

Execution of Purging

Start the gas source and gradually increase flow.

Monitor pressure and flow to ensure complete impurity removal.

Inspection of Results

Conduct visual checks or flow sampling.

Extend purging time if residual debris is detected.

System Test Run

After purging, run the system to confirm stable and safe operation.

4. Common Issues and Troubleshooting

Unstable Gas Source Pressure

Leads to ineffective purging or equipment damage.

Solution: Adjust source with a pressure control valve.

Pipeline Leakage

Causes gas loss and poor purging performance.

Solution: Check all flanges, gaskets, and joints.

Incomplete Debris Removal

Results in later blockages.

Solution: Extend purge duration or use higher flow.

Improper Operation

Incorrect flow rate, loose connections, or poor monitoring may cause failure.

Solution: Operators must be trained and follow standard operating procedures (SOP).

5. Post-Purging Actions

Documentation and Reporting

Record time, pressure, flow rate, and results for traceability.

System Inspection

Check sealing, valves, and connections after purging.

Regular Maintenance

Purging should be repeated during overhauls or component replacements.

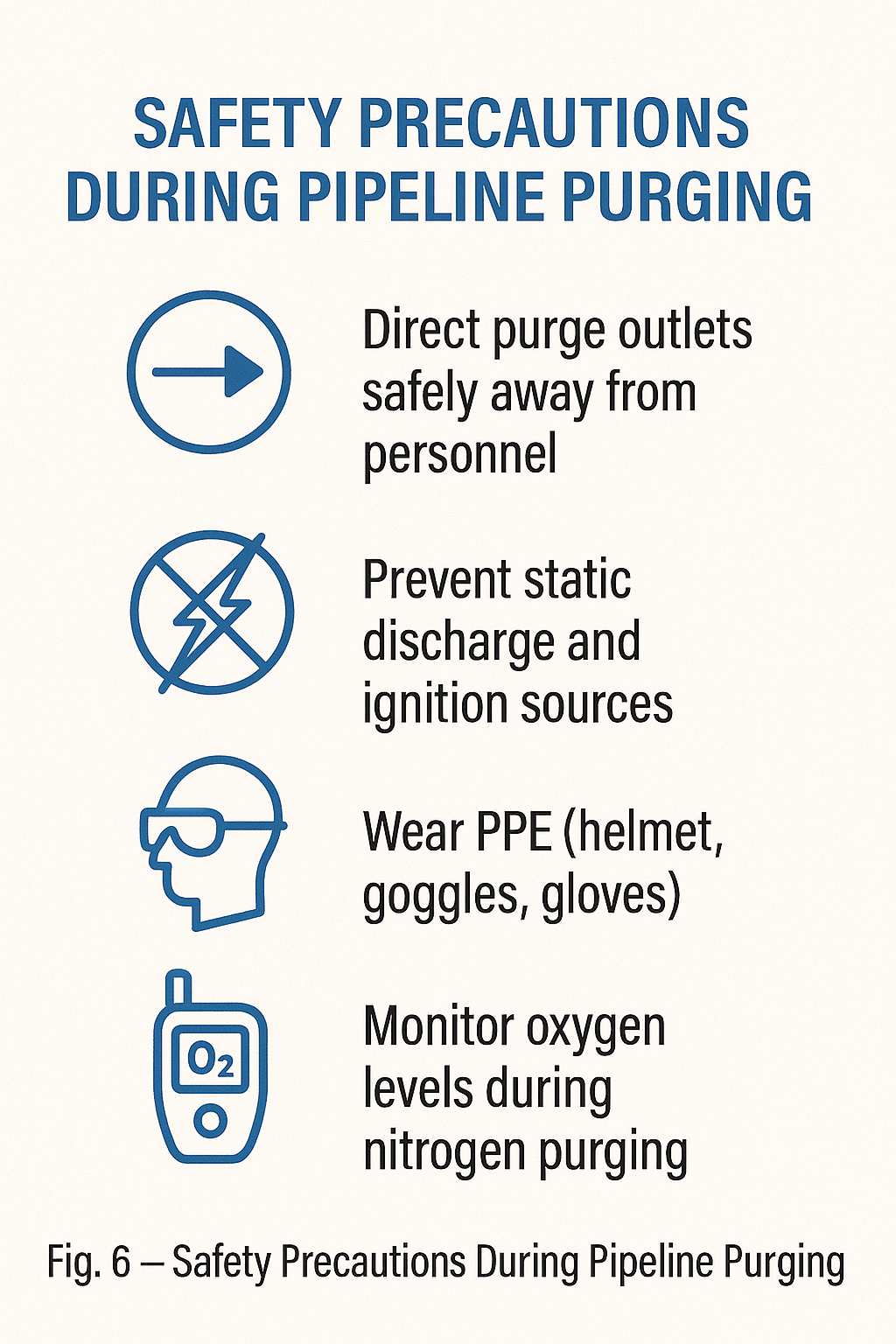

6. Safety Considerations

Ensure that purge outlets are directed safely away from personnel.

Prevent static discharge and ignition sources near purge gas outlets.

Operators should wear PPE (helmets, goggles, gloves).

Nitrogen purging requires oxygen monitoring to avoid asphyxiation risks.

7. Conclusion

Pipeline purging is a critical procedure for maintaining system safety and equipment longevity. By following standard procedures, monitoring purging effectiveness, and implementing safety measures, companies can minimize risks, reduce downtime, and ensure long-term system stability.