Abstract

Power dips (voltage sags) are common disturbances in industrial power grids. If not handled properly, they may cause equipment trips, process interruptions, or even secondary accidents such as material leakage or equipment damage. This document provides technical guidance on how to ensure orderly equipment operation during power dips through PLC/DCS program optimization and emergency logic design, with a focus on risk mitigation in continuous production environments (e.g., asphalt loading systems).

1. PLC/DCS Program Optimization

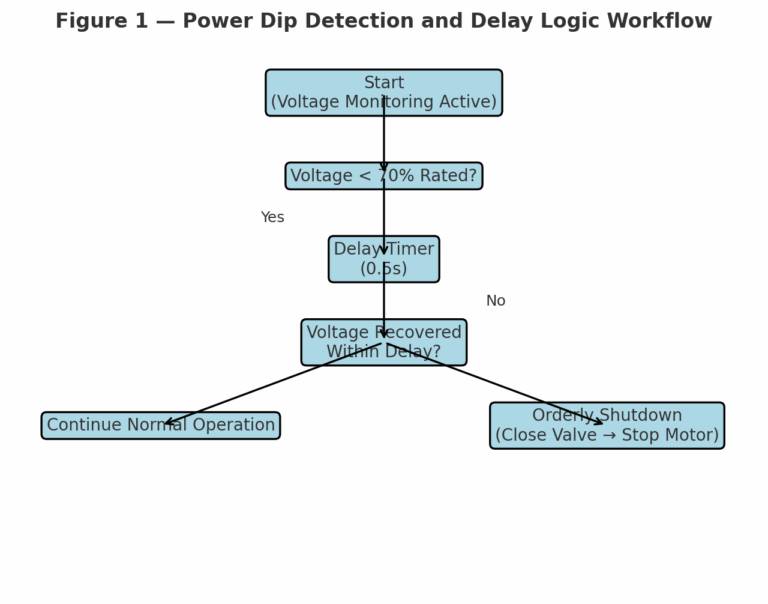

1.1 Power Dip Detection and Delay Logic

A voltage monitoring module should be integrated into the control system to track real-time grid conditions.

Trigger threshold: when voltage drops below 70% of the rated value.

Delay logic: if the voltage recovers within 0.5 seconds, no shutdown command is executed.

Orderly shutdown: if the voltage drop persists, initiate sequential shutdown, e.g.,

Close feed valves;

Stop motors;

Isolate auxiliary systems.

This prevents material blockage and equipment damage.

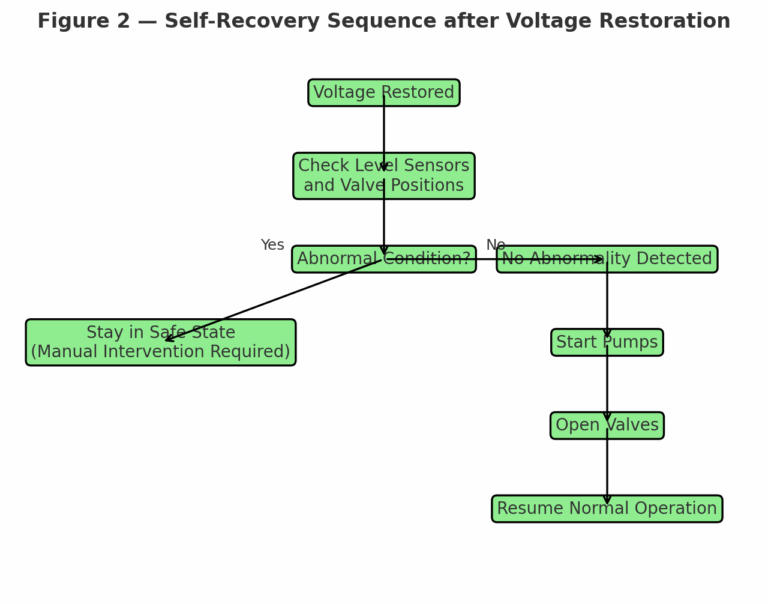

1.2 Automatic Recovery Logic

For continuous processes (e.g., asphalt truck loading), a “self-restart sequence” should be embedded in the program:

After voltage recovery, verify level sensors and valve positions.

Confirm no abnormal conditions.

Restart pumps → open valves → resume operations.

This minimizes manual intervention and shortens downtime.

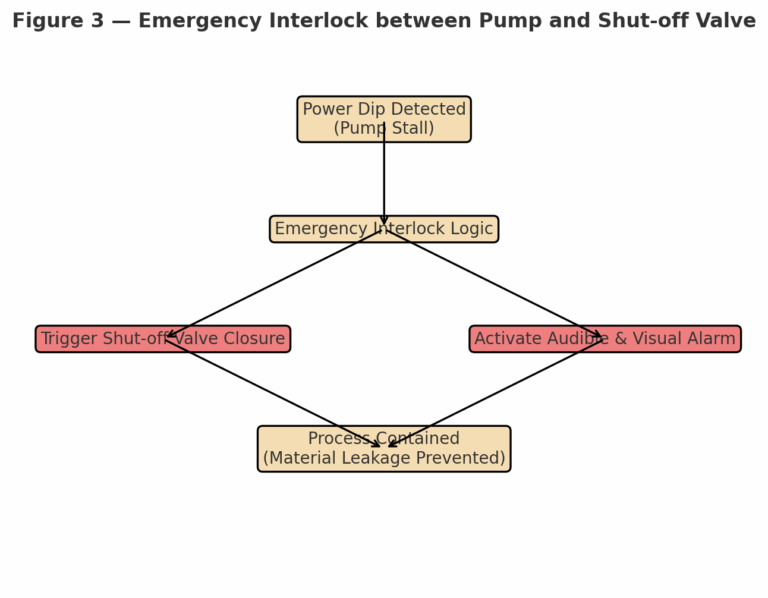

2. Emergency Interlocks and Alarm Mechanisms

2.1 Interlocks with Safety Devices

If a pump stalls during a power dip:

Immediately trigger emergency shut-off valves (ESD valves) at loading arms.

Prevent product leakage and ensure process containment.

Simultaneously activate audible and visual alarms to alert field operators.

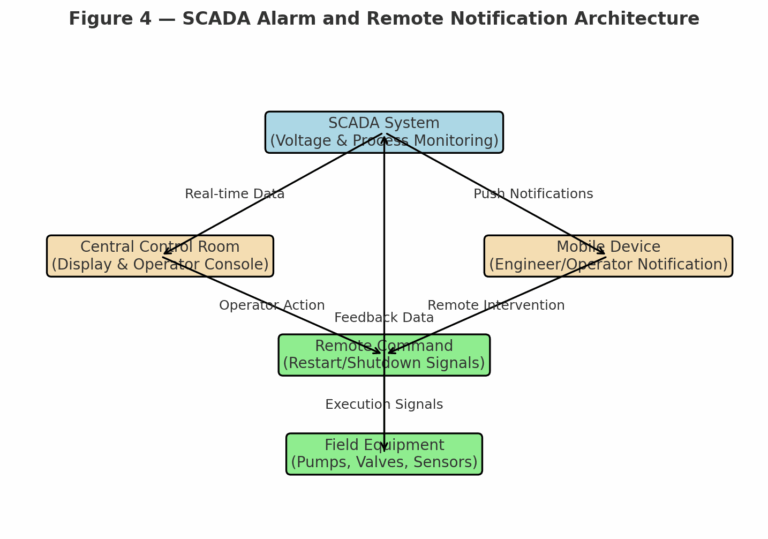

2.2 Remote Monitoring and Intervention

By integrating SCADA systems, operators can remotely supervise equipment status:

Real-time monitoring of grid voltage and process variables.

Automatic push notifications to operators’ mobile devices or central control rooms when a power dip occurs.

Remote intervention: engineers can issue recovery commands even at unmanned or remote sites.

3. Risk Control and Design Considerations

Fail-safe principle: if automatic recovery is not possible due to abnormal signals, the system must remain in a safe shutdown state.

Redundancy: key interlock signals (e.g., valve closed feedback) should have redundant verification to avoid false actions.

Testing: regular simulation of power dip scenarios should be conducted to verify sequence reliability.

Conclusion

Through program optimization (detection, delay, recovery) and emergency interlocks (safety cut-off, alarms, remote monitoring), industrial automation systems can significantly reduce the impact of power dips. These measures ensure continuity of production, minimize safety risks, and improve system resilience.