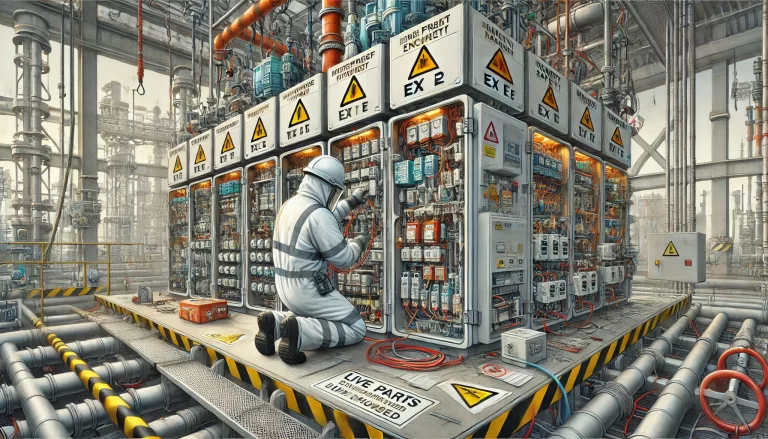

1. Explosion-Proof Requirements

All electronic instruments installed in hazardous areas shall comply with IEC 60079 or GB 3836 standards, and must be certified with valid national explosion-proof certificates.

1.1 Zone 0: Use intrinsically safe instruments (EEx i) with isolation-type safety barriers.

1.2 Zone 1 & Zone 2: Explosion-proof type (EEx d) shall be the first choice.

1.3 Junction Boxes in Zone 1 & 2: Use increased safety type (EEx e) or explosion-proof type (EEx d).

2. Flammable and Toxic Gas Detection

In areas where flammable or toxic gases may leak or accumulate, and at building fresh-air inlets:

2.1 Fixed gas detectors shall be installed and connected to an independent GDS (Gas Detection System) AI rack or AI card.

2.2 The central control room (CCR) shall be equipped with a dedicated GDS operator station and independent audible/visual alarm devices.

2.3 On-site gas detectors should have local audible/visual alarm functions.

2.4 Portable multi-gas detectors (four-in-one type) shall be provided according to process characteristics.

2.5 Gas detectors must use dedicated junction boxes and shielded cables.

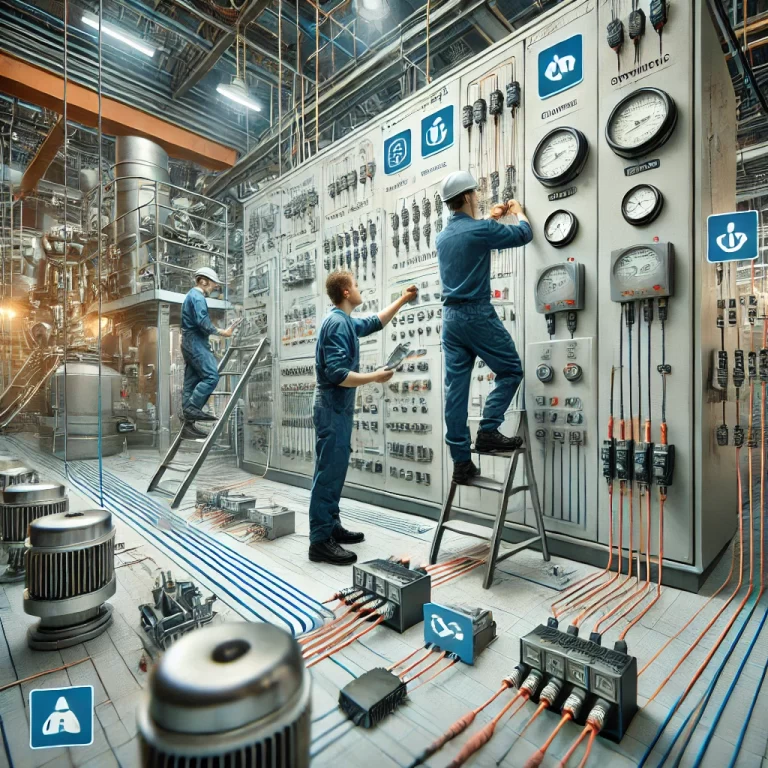

3. Grounding System

3.1 An equipotential grounding system shall be used. Instrument control system shall have both working ground and safety ground, which are bonded together and connected to the plant grounding grid using dual grounding cables.

3.2 Field panels, analyzer shelters, cable trays, instruments, junction boxes, and sealing fittings shall be directly grounded to the plant grid via structural frames.

3.3 Working ground shall be connected to the instrument working ground busbar in the control system.

4. Lightning Protection

4.1 Instruments outside the electrical lightning protection zone shall be equipped with surge protection devices (SPD) at both field and control system sides.

4.2 Cable entries into CCR, FAR (Field Auxiliary Room), and FCR (Field Control Room) shall maintain a clearance of ≥2000 mm from lightning down-conductors.

5. Toxic Substances

5.1 For highly toxic media, use diaphragm-sealed instruments and bellows-sealed valves to prevent leakage.

6. Corrosive Substances

6.1 Instruments for corrosive service shall use diaphragm seals and materials resistant to the specific process fluid.

7. Noise Hazards

7.1 Control valve noise shall be ≤85 dBA; intermittent operating valves shall be ≤105 dBA.

7.2 Noise reduction measures such as silencers, low-noise trim, or acoustic enclosures shall be adopted.

8. High-Temperature Protection

8.1 Instruments and valves exposed to high temperature shall adopt extended-neck or finned designs to reduce surface temperature and prevent burns.

9. Radioactive Instruments

9.1 Radiation-based instruments shall have clear warning signs and comply with GBZ 114–2002 and GBZ 125–2002 standards.

9.2 Video surveillance shall be installed for monitoring.

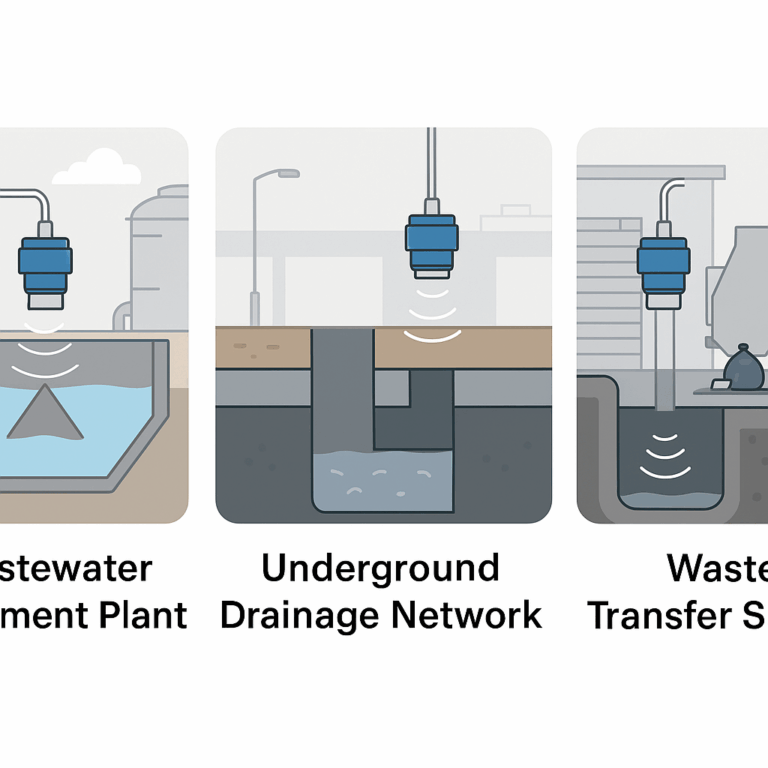

10. Environmental Protection

10.1 Wastewater outlets shall be equipped with online analyzers (e.g., COD, TOC, pH, ammonia) to ensure compliance with environmental regulations.

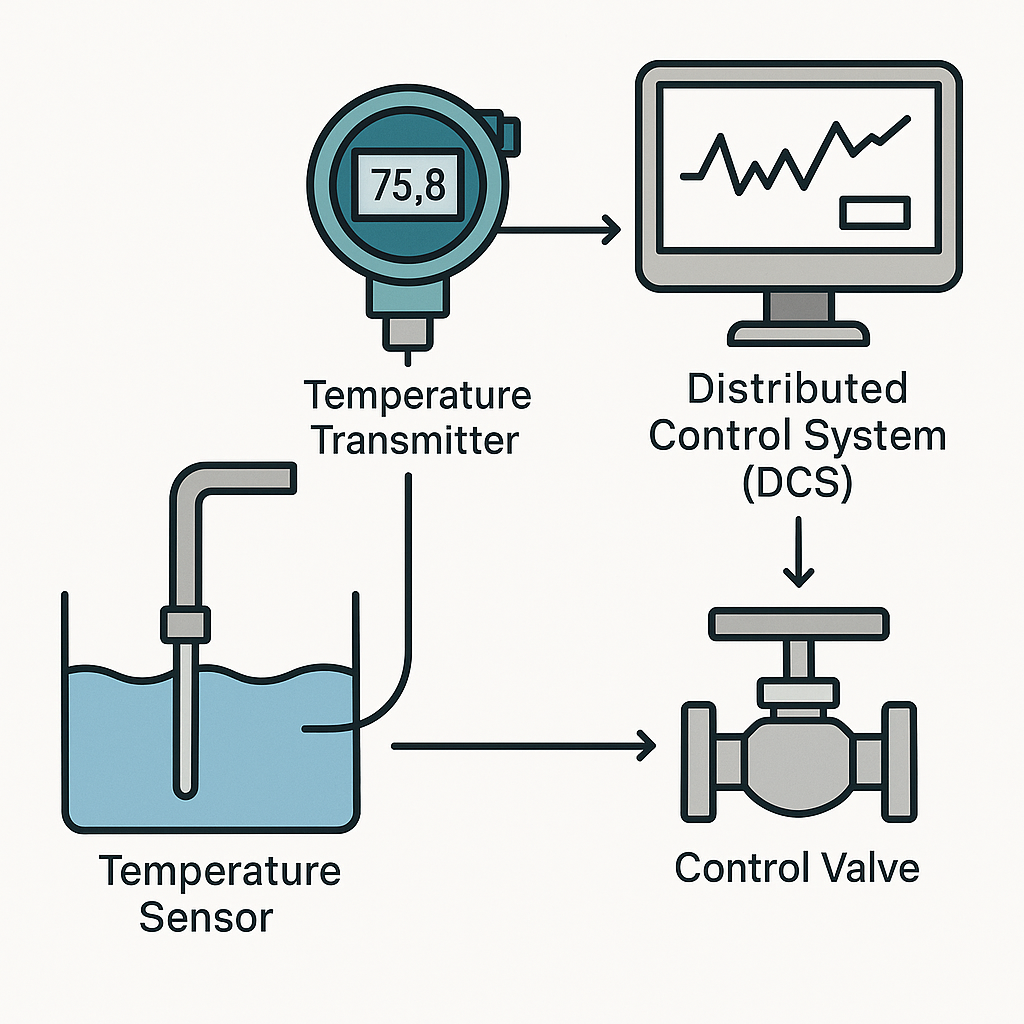

11. Safety Instrumented System (SIS)

11.1 A Safety Instrumented System shall be provided according to process requirements, meeting at least SIL 3 level.

11.2 The system design shall be fail-safe type to ensure safe plant operation.

12. Control Room Safety

12.1 The control building shall have a dedicated HSE office and fire monitoring room.

13. Electrical Safety

13.1 All terminals and busbars rated above 220 V shall be insulated and clearly labeled with warning signs to prevent accidental electric shock.

14. Fire Protection

14.1 Shut-off valves for flammable media pipelines shall be designed with fire-proof structures to prevent escalation during fire incidents.

15. Level Measurement

15.1 Glass tube level gauges are strictly prohibited for flammable/toxic media.

15.2 If glass plate level gauges are used, they must be equipped with steel ball self-sealing devices for safety.

Conclusion

This specification outlines mandatory requirements for explosion protection, gas detection, grounding, lightning protection, toxic and corrosive media handling, noise control, fire prevention, environmental monitoring, and safety instrumented systems. It ensures compliance with IEC, GB, and HSE standards, enhancing both safety and reliability in industrial operations.