Introduction

In industrial automation and process control, the Modbus protocol is one of the most widely used communication standards. At the heart of Modbus lies the concept of the coil, a fundamental data type that plays a crucial role in device control and monitoring. This article explains what coils are, how they work, and why they are so important in modern control systems.

What Are Modbus Coils?

A coil in Modbus represents a binary state — either ON (1) or OFF (0). It can be imagined as a switch or a relay contact. Coils are used to store and transmit simple boolean information, making them ideal for representing the state of discrete devices.

Example: A coil may indicate whether a motor is running (1) or stopped (0), or whether a valve is open (1) or closed (0).

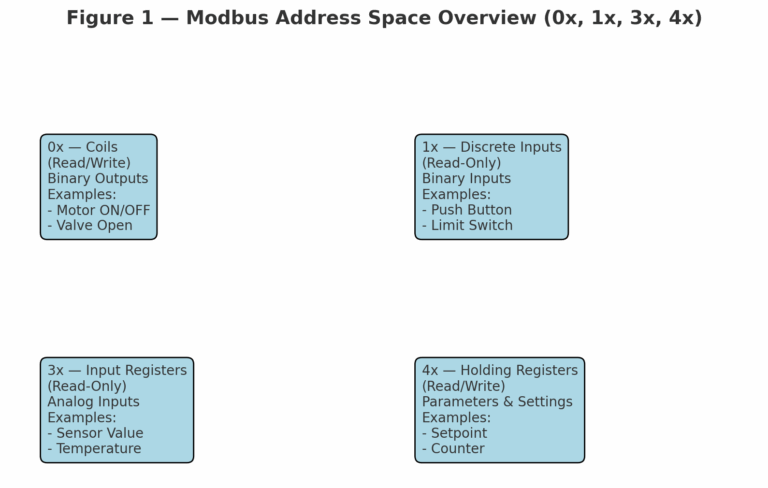

Types of Modbus Data Objects

Modbus defines four categories of data objects. Although in practice many engineers loosely refer to all of them as “coils,” strictly speaking, they are distinct:

Coils (0x)

Read/Write

Represent discrete outputs (e.g., turning a pump ON/OFF).

Discrete Inputs (1x)

Read-Only

Represent external digital inputs (e.g., limit switches, push buttons).

Input Registers (3x)

Read-Only

Store analog input data (e.g., sensor measurements).

Holding Registers (4x)

Read/Write

Store system parameters and analog values (e.g., setpoints, counters).

👉 Key Clarification: Only Coils and Discrete Inputs are truly “binary coils.” Input and Holding Registers are 16-bit word registers used for analog or configuration data.

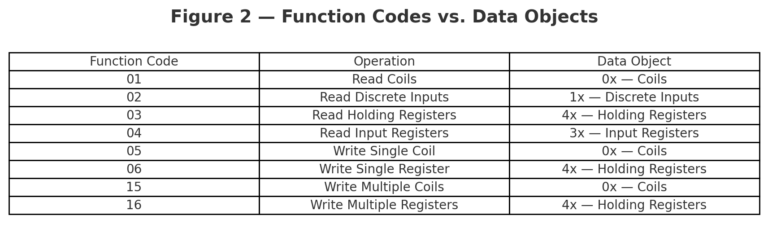

How Do Modbus Coils Work?

Modbus follows a Master–Slave (or Client–Server) architecture. The master device sends commands, and the slave responds. Coils are manipulated using specific function codes:

Function Code 01 — Read Coils: Reads one or more coil states.

Function Code 02 — Read Discrete Inputs: Reads input statuses.

Function Code 05 — Write Single Coil: Sets the state of a single coil.

Function Code 15 — Write Multiple Coils: Sets the state of multiple coils.

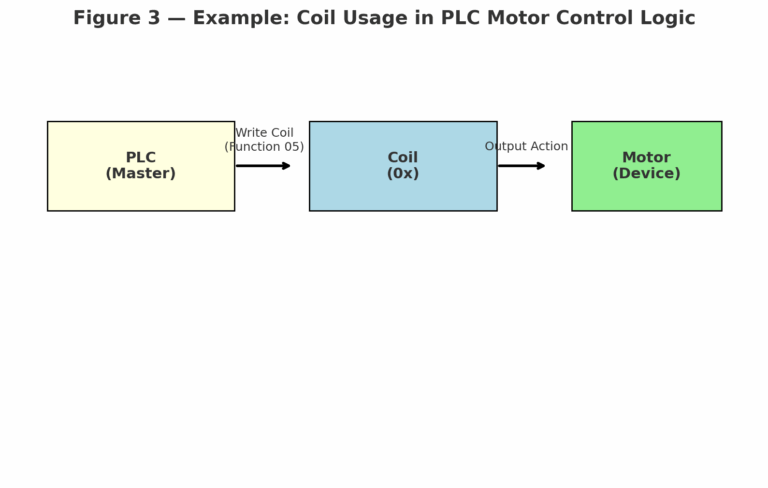

Example Application:

To start a motor, the master sends a Write Single Coil (05) command, setting the corresponding coil to 1. The slave then executes the action and confirms the status back to the master.

Why Are Coils Important?

Coils simplify communication between controllers and field devices, providing a clear, efficient way to handle discrete control. Their importance lies in:

Simplicity: Binary ON/OFF states are intuitive and easy to use.

Efficiency: Lightweight function codes allow fast communication.

Universality: Supported across nearly all PLCs, DCS systems, and smart instruments.

Versatility: Suitable for building automation, energy management, manufacturing, and beyond.

Example Applications of Modbus Coils

Building Automation: Light and HVAC control via coil switching.

Industrial Manufacturing: Start/stop motors, conveyors, or pumps.

Process Control: Remote valve actuation and safety interlocks.

Energy Systems: Breaker status monitoring and load control.

Conclusion

Modbus coils act as the bridge between physical devices and digital communication. Whether controlling a motor, reading a sensor, or transmitting status signals, coils provide the most fundamental mechanism for real-time interaction in industrial automation.

By clearly understanding how coils and registers are structured and used, engineers can design more reliable, efficient, and scalable control systems.