01. Why Establish an Instrument Ledger?

1.1 Clarify Asset Inventory

A well-maintained instrument ledger helps answer three foundational questions:

How many instruments are installed in the plant?

What are their models and technical parameters?

Where are they installed, specifically?

Many facilities struggle to provide immediate answers to these questions. A precise ledger serves as a visual “asset map,” enabling scientific management.

1.2 Foundation for Standardized Management

Instruments have long life cycles, spanning procurement, installation, commissioning, operation, maintenance, and decommissioning. Without a ledger, it is impossible to achieve full life-cycle traceability and accountability.

A complete ledger becomes a chronological “growth file” for each instrument—critical for precise, data-driven management.

1.3 Basis for Maintenance Planning

Routine inspections, overhauls, and annual calibrations should not be based on guesswork. They must be grounded in the data captured in the ledger.

For example:

Critical instruments: monthly calibration

Secondary instruments: annual calibration

With structured data, plans become targeted and efficient.

1.4 Accelerated Fault Diagnosis and Root Cause Tracing

When a fault occurs, quick access to the instrument’s model, serial number, and maintenance history allows technicians to determine whether the issue stems from the device itself, installation errors, or external interference. This greatly reduces downtime and financial losses.

1.5 Data-Driven Decision Making

Instrument ledger data supports not only daily operations but also long-term strategic planning. For example:

Estimate average service life to inform replacement plans

Analyze maintenance frequency to evaluate supplier performance

Monitor spare part consumption to reduce inventory costs

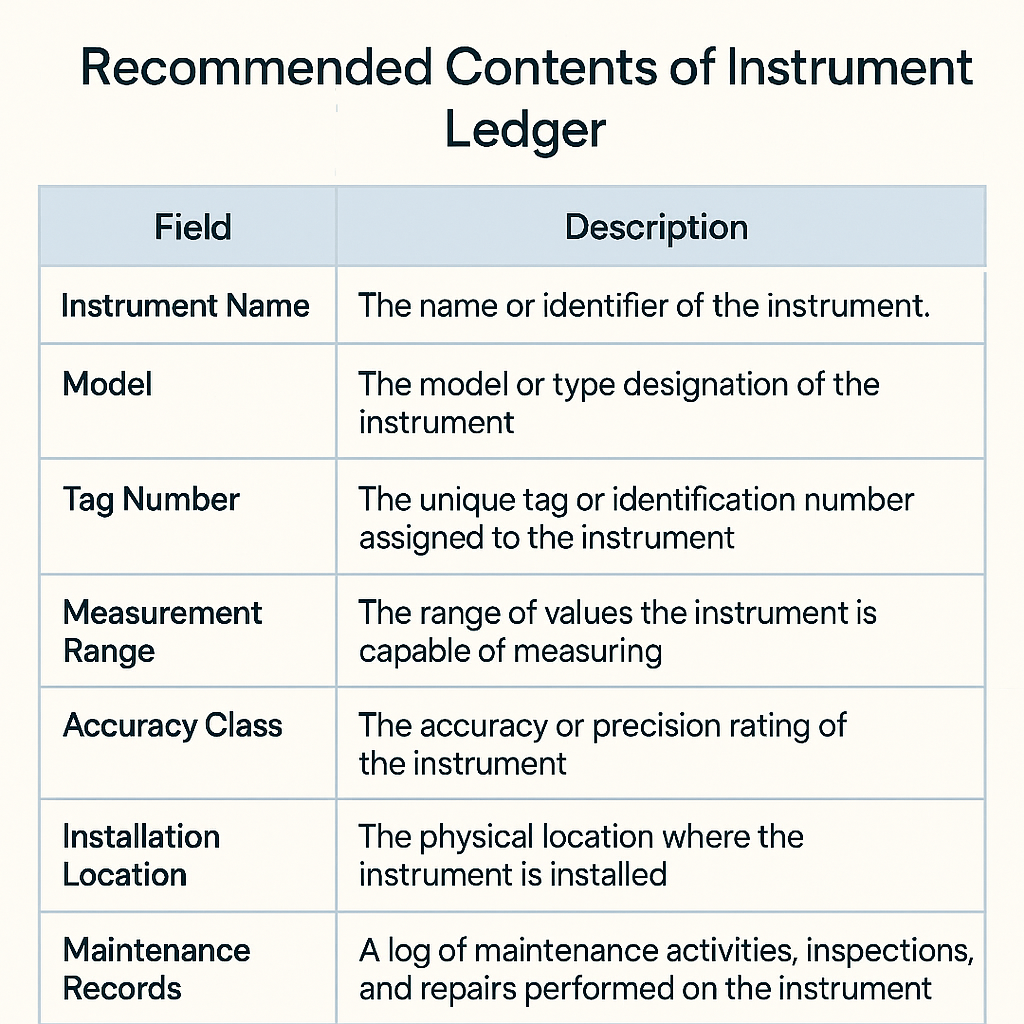

02. Recommended Contents of an Instrument Ledger

An effective instrument ledger should include at minimum the following fields:

| Field | Description |

|---|---|

| Instrument Name | E.g., Pressure Transmitter, RTD, Level Gauge |

| Model & Specification | Full technical model for compatibility |

| Serial Number | Unique identifier for traceability |

| Tag Number | As per P&ID, links to installation location |

| Measuring Range | E.g., 0-100 kPa, 0-500°C |

| Accuracy Class | E.g., 0.5% FS, 1.0 Class |

| Medium | Water, steam, gas, oxygen, etc. |

| Installation Location | Workshop – Equipment – Pipeline – Point |

| Linked Control Function | Whether part of interlock or cascade control |

| Operational Status | Running, Standby, Out of Service, Retired |

| Manufacturer | For tech support and warranty follow-up |

| Commissioning Date | Basis for lifecycle assessment |

| Calibration Cycle | E.g., Monthly, Annually |

| Last Calibration Date | To ensure timeliness |

| Maintenance Records | Date, Content, Result, Responsible Person |

| Documentation Links | QR codes linking to manuals or datasheets |

Additional fields may include: nominal diameter, flange standard, pressure rating, migration amount, etc.

Principle: Any information that aids rapid on-site troubleshooting should be included.

03. How to Manage and Optimize Your Instrument Ledger

3.1 Detailed Yet Concise

Capture all essential parameters but avoid unnecessary text. Field values should be clear and intuitive for operators.

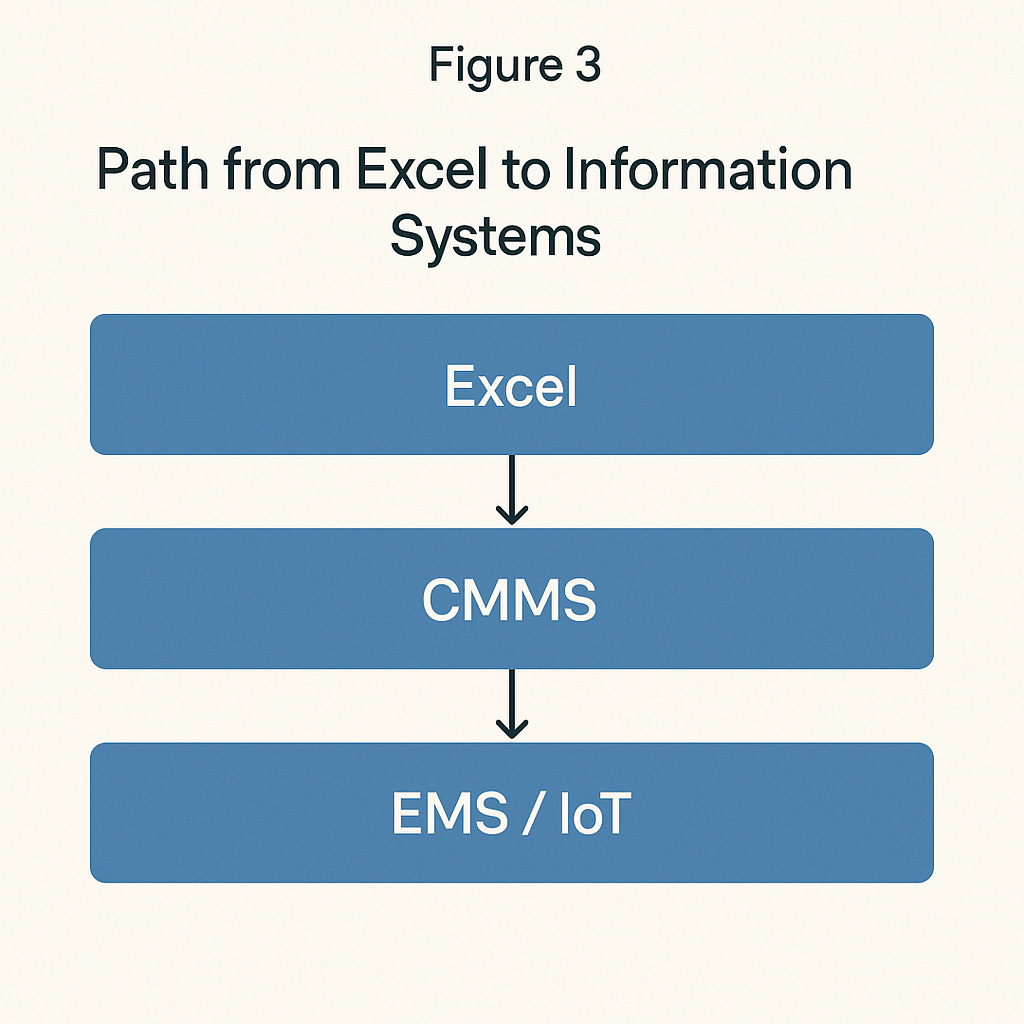

3.2 Go Digital

Paper records are no longer sufficient. Start with Excel and gradually evolve to advanced systems:

Excel: Quick entry and query

CMMS/EAM: Centralized platform with access control

EMS/IoT: Lifecycle data accessible via QR code scans

3.3 Establish Dynamic Update Mechanisms

The ledger must be a living document. Suggested update triggers:

New equipment commissioned: immediate registration

After every calibration or repair: update records

Periodic reviews: remove decommissioned units

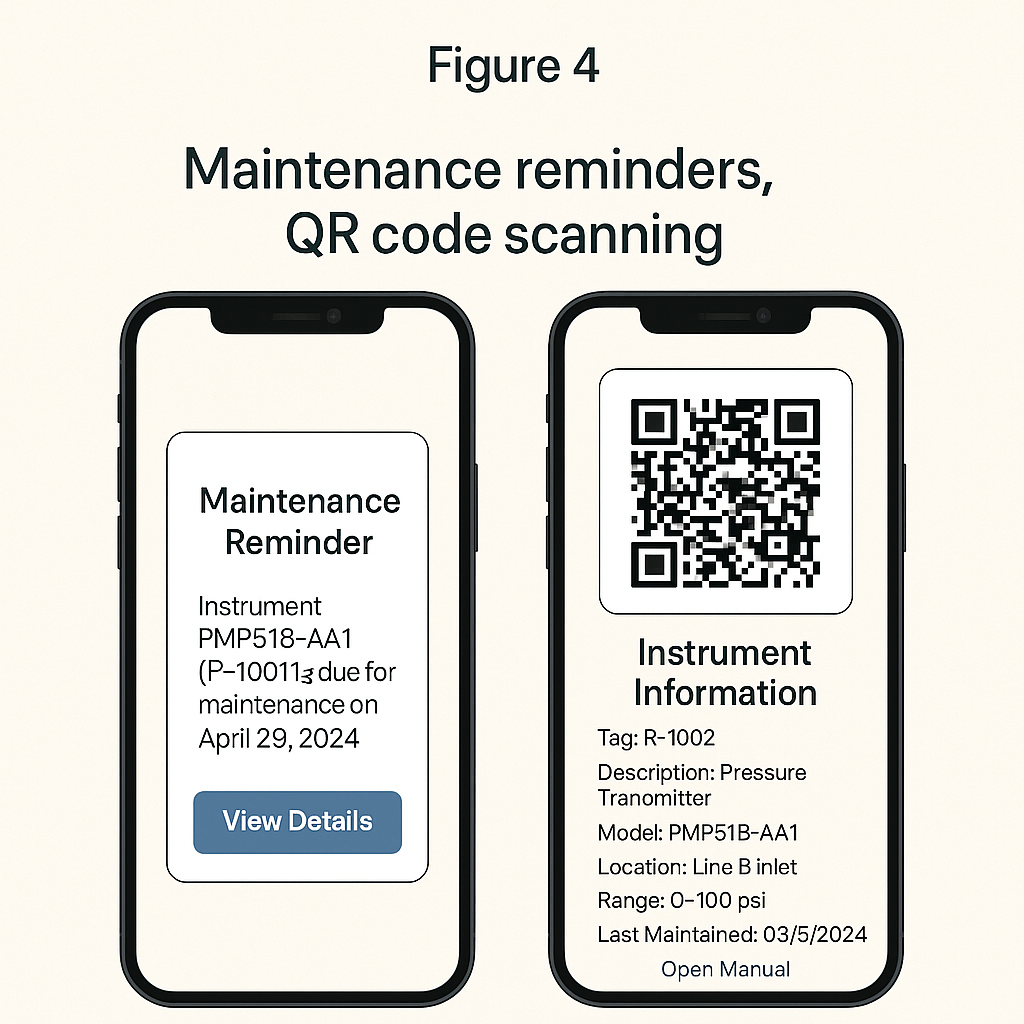

3.4 Embrace Information Technology

Modern systems allow for:

Mobile scanning: Retrieve instrument info on-site

Auto reminders: Push notifications for upcoming calibration

Predictive analytics: Use history to build failure pattern databases

Example: One plant implemented a CMMS system covering thousands of instruments and achieved:

20% reduction in overhaul scheduling time

35% drop in unexpected failures

15% decrease in spare parts inventory costs

04. Implementation Tips for Large Facilities

4.1 Start Small

Don’t attempt a full rollout all at once. Prioritize critical areas (e.g., blast furnace, boiler systems) before scaling up.

4.2 Define Roles Clearly

Assign responsibilities for data entry, maintenance, and review to ensure accountability.

4.3 Integrate with Drawings and On-Site Checks

Always validate ledger entries against P&ID drawings and physical inspections to avoid discrepancies between records and reality.

4.4 Introduce QR/Barcode Labels

Affix QR codes or barcodes to each instrument. Scanning them gives instant access to device specs, records, and manuals.

05. Conclusion

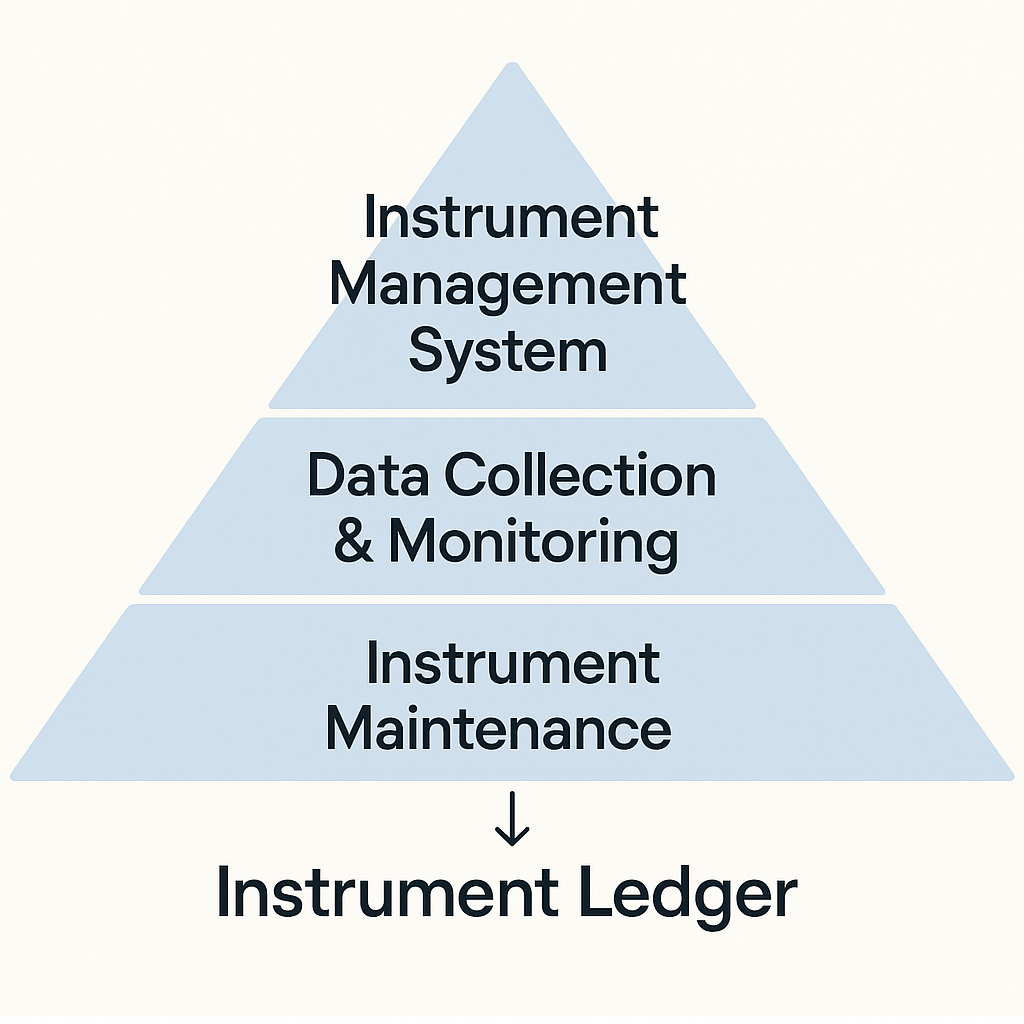

An instrument ledger is not an optional accessory—it is the foundation of an effective instrumentation management system. It improves maintenance efficiency, reduces failure rates, and empowers data-informed planning.

By getting this “foundation” right, you pave the way for more stable operations, lower costs, and enhanced plant safety.

Start with a solid ledger. Master the rest of instrumentation management from there.