Introduction

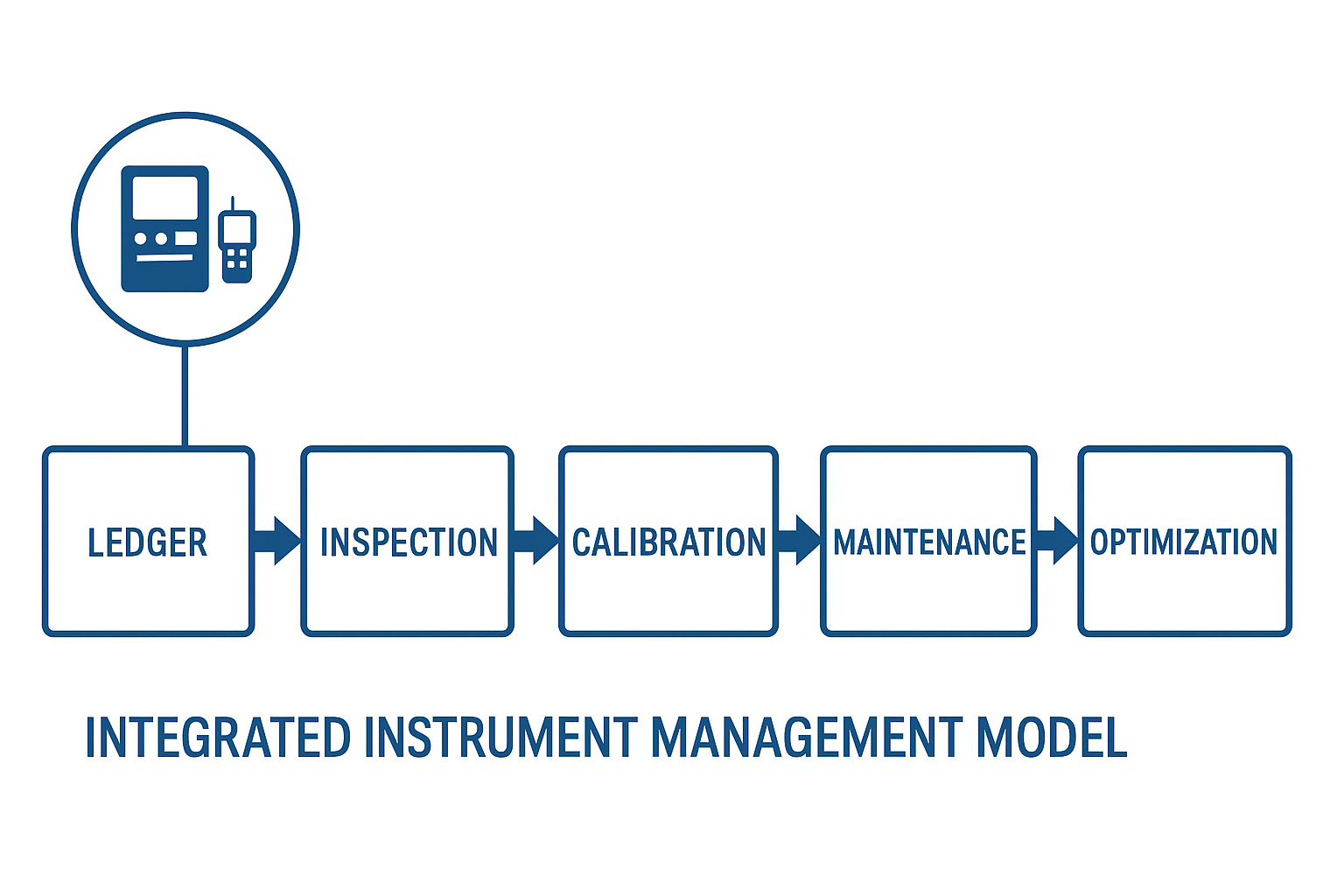

After completing the first step of instrument management—establishing a comprehensive and accurate instrument ledger—we hold in hand a precise “map” and “directory” of all devices. However, static data alone cannot ensure reliability. The true value of the ledger lies in transforming this information into systematic actions.

The second step of instrument management is to implement periodic inspection, calibration, and preventive maintenance. This is the bridge between “knowing” and “doing,” and the core engine for ensuring long-term, stable, and reliable instrument operation.

1. Why Step Two Is Critical

Instruments are not “install-and-forget” devices. Operating under harsh conditions such as high temperature, pressure, corrosion, and vibration, their accuracy and performance naturally drift or degrade over time. Even small deviations may lead to severe consequences:

Product quality degradation: A deviation of just 1°C in reaction temperature may cause an entire batch to fail.

Safety hazards: Failure of pressure or level instruments can trigger major industrial accidents.

Increased energy and material consumption: Inaccurate flowmeter readings result in invisible losses.

Unplanned shutdowns: Failure of critical control instruments often forces production lines to stop, leading to huge economic losses.

Thus, waiting for failure before taking action is costly. Step Two emphasizes preventive and proactive management, identifying potential faults early through systematic inspections and maintenance, ensuring continuous, safe, and efficient operations.

2. Three Core Tasks: Inspection, Calibration, and Maintenance

Together, these tasks form a “protection network” for instrument health.

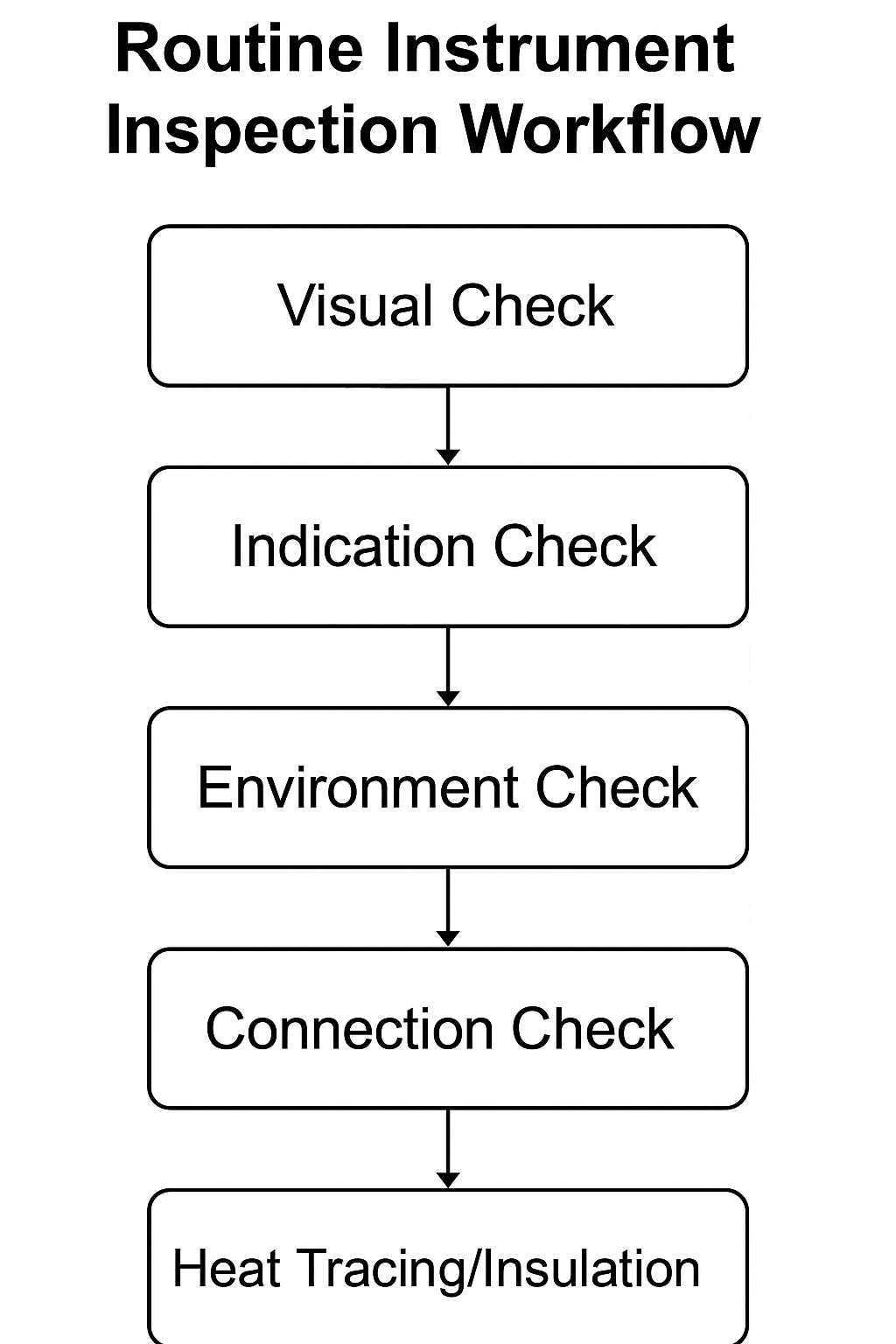

2.1 Periodic Inspection

Inspection is the most frequent and fundamental task, relying heavily on operator responsibility and experience.

Key items:

Visual check: Body, glass, nameplate integrity; sealing parts for aging; signs of damage, dirt, oil, or looseness.

Indication check: Local display for normal reading without freezing, flickering, or overscale; compare control room readings with actual process values.

Environment check: Temperature, humidity, vibration compliance; protection against dust, rain, and corrosive media.

Connection check: Tightness of impulse lines, cable joints, and glands; no leakage or corrosion.

Heat tracing/insulation: Winter protection to avoid medium freezing.

Execution points:

Prepare standardized inspection SOPs, specifying routes, tasks, and cycles (per shift, daily, weekly).

Record abnormal findings in detail for follow-up.

2.2 Periodic Calibration

Calibration ensures the accuracy and traceability of measurement results.

Core concept:

Use a reference standard with 3–10 times higher accuracy to verify and adjust instrument zero, span, and linearity.

Regulatory requirements:

Instruments related to safety, environment, or trade settlement must undergo mandatory verification according to national metrology regulations.

Calibration cycle:

Follow manufacturer’s recommended intervals.

Adjust cycle based on historical stability and criticality of application (shorter for safety-critical loops).

Execution points:

Conduct calibration only by certified professionals.

Perform tests at 0%, 25%, 50%, 75%, and 100% span (up and down scale).

Record data in detail, issue calibration certificates, and apply status labels (Pass, Restricted, Out-of-service).

Instruments that cannot be restored due to aging or severe damage must be scrapped following company procedures.

2.3 Preventive Maintenance

Unlike repair, maintenance is performed before performance deterioration to extend instrument life.

Tasks include:

Cleaning: Remove dust, oil, and corrosion.

Lubrication and tightening: Apply grease to moving parts; secure electrical and mechanical connections.

Functional testing: Stroke test for control valves; action test for on/off valves.

Replacement of consumables: Filters, seals, cables, or other wear-prone parts.

Execution points:

Integrate maintenance tasks with calibration schedules (“calibration + maintenance together”).

Conduct functional tests after maintenance to confirm reliability.

3. Effective Implementation

Plan generation:

Based on the instrument ledger, define unique inspection, calibration, and maintenance cycles for each device.

Use CMMS (Computerized Maintenance Management System) or EAM (Enterprise Asset Management) to automatically generate periodic work orders.

Assignment & execution:

Work orders are assigned to technicians.

Technicians follow standardized procedures with proper tools.

Record & feedback:

Results (inspection findings, calibration data, replaced parts) are logged into the instrument’s “electronic health record.”

Analysis & optimization:

Conduct reliability analysis on collected data.

Continuously refine cycle strategies through the PDCA loop (Plan–Do–Check–Act).

Conclusion

Step Two of instrument management is not simple repetitive labor. It is a strategic process combining technology, management, and expertise. By transforming static ledger data into dynamic preventive actions, enterprises can:

Enhance safety and reliability.

Improve product quality and compliance.

Reduce costs and resource consumption.

Ensure sustainable and efficient operations.

The ledger is the starting point, but periodic inspection, calibration, and maintenance are the heartbeat of the management system. Consistently executing this step ensures instruments remain the “eyes and hands of industry,” safeguarding excellence in operation.