Introduction

In industrial automation, RS-485 communication has become one of the most widely used methods for data exchange between devices. Thanks to its reliability, strong noise immunity, and long-distance capability, it is commonly found in factory automation, building control, and energy monitoring systems.

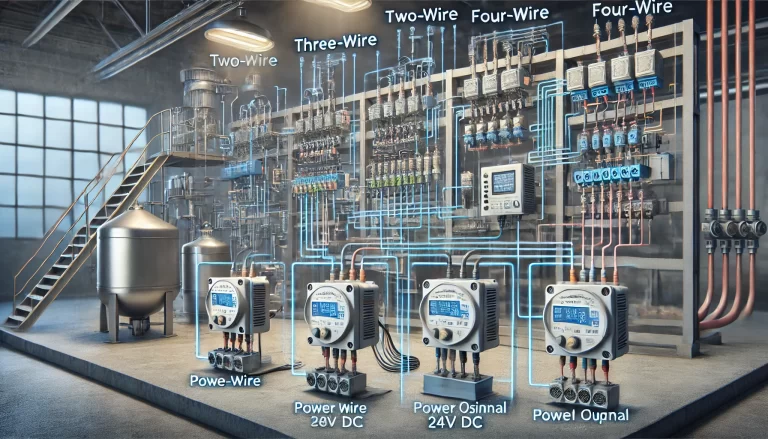

However, RS-485 is not a single wiring method. It can be implemented in two-wire (half-duplex) or four-wire (full-duplex) configurations. While the difference may seem as simple as “two additional wires,” the choice has a significant impact on communication efficiency, interference resistance, cost, and installation complexity.

This article provides a structured comparison of the two approaches, including principles, advantages, limitations, application scenarios, and selection guidelines.

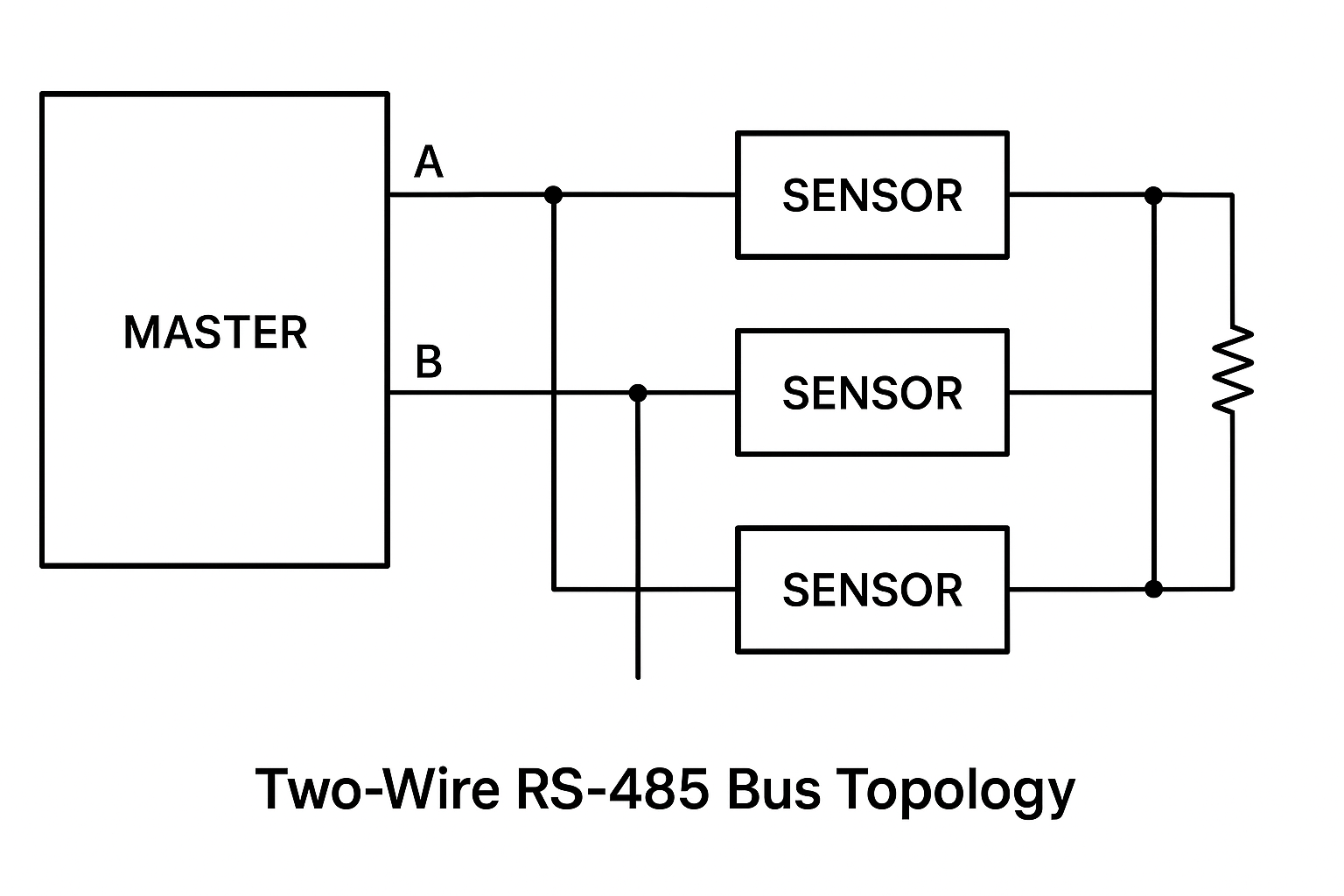

1. Two-Wire RS-485 (Half-Duplex)

Principle:

Only two differential lines (A/B) are required for both transmitting and receiving data. Communication is half-duplex—devices either send or receive at a given time, but not simultaneously.

Advantages:

Simple wiring, minimal cable requirement.

Cost-effective and easy to install/maintain.

Suitable for small-scale systems with low communication frequency.

Limitations:

Limited throughput due to half-duplex mode.

Signal attenuation may occur in large networks or long distances.

More susceptible to noise in harsh environments.

📌 Typical Applications

Data acquisition from dozens of field sensors.

Monitoring systems with low real-time requirements and cost sensitivity.

Analogy:

Two-wire RS-485 is like a compact, fuel-efficient car—perfect for daily commuting, but not designed for high-speed racing.

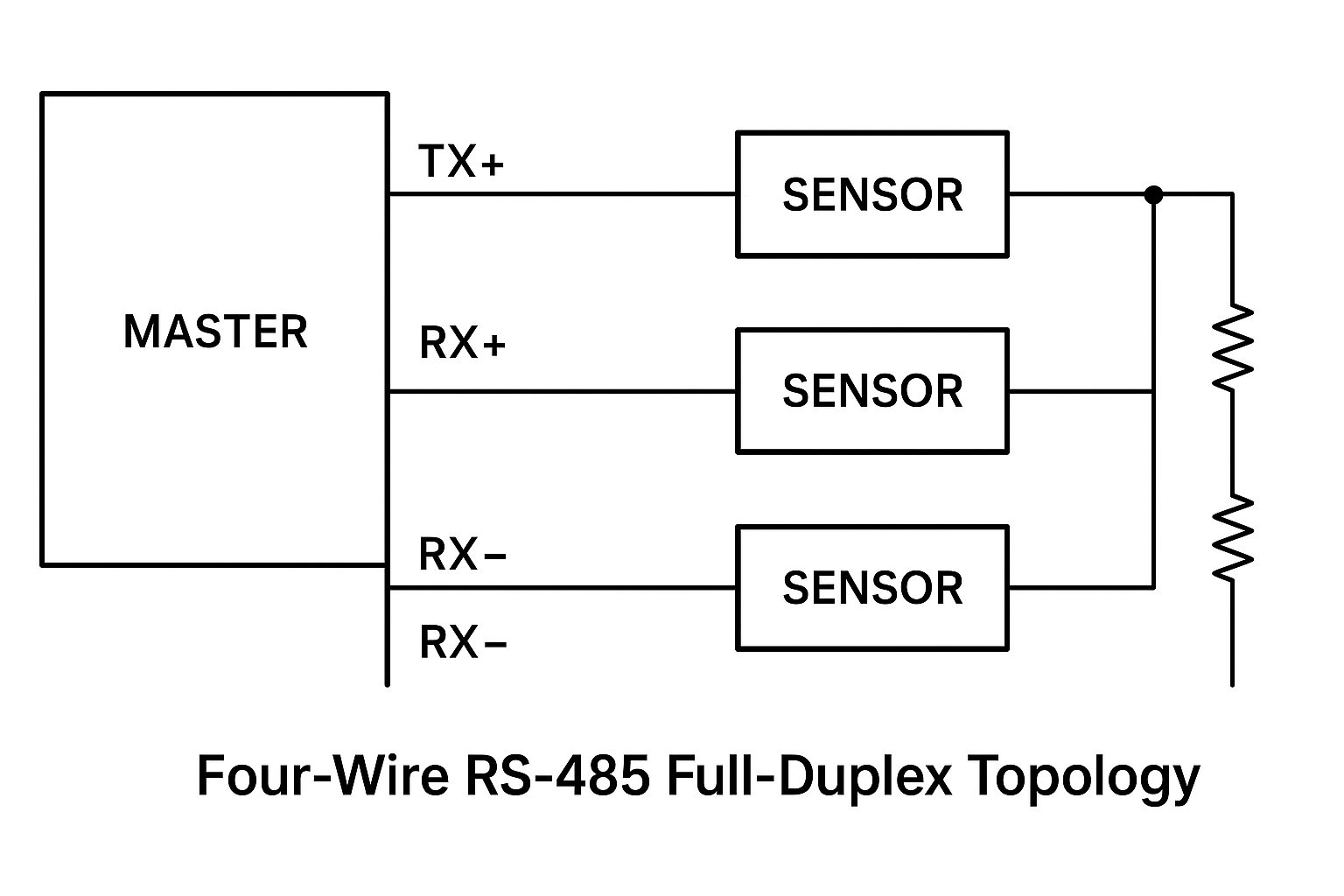

2. Four-Wire RS-485 (Full-Duplex)

Principle:

In addition to the two differential lines (A/B), an extra pair of lines is added, separating TX (transmit) and RX (receive) signals. This allows simultaneous sending and receiving of data.

Advantages:

Full-duplex communication doubles efficiency.

Stronger noise immunity and higher data integrity.

More reliable for long-distance transmission and high baud rates.

Limitations:

Increased wiring and installation complexity.

Higher overall cost.

Requires more careful debugging and grounding design.

📌 Typical Applications

High-speed communication between PLCs and variable frequency drives (VFDs).

Large-scale distributed control systems (DCS).

Harsh electromagnetic environments requiring stable communication.

Analogy:

Four-wire RS-485 is like a high-speed railway—higher investment, but superior speed and stability.

3. Key Selection Criteria

When deciding between two-wire and four-wire RS-485, engineers should evaluate the following aspects:

Communication Efficiency

Two-Wire: Half-duplex, suitable for low-speed or non-critical timing applications.

Four-Wire: Full-duplex, supports high-speed and real-time applications.

Cost & Installation

Two-Wire: Fewer cables, easier installation, cost-effective.

Four-Wire: More cables and complexity, higher project cost.

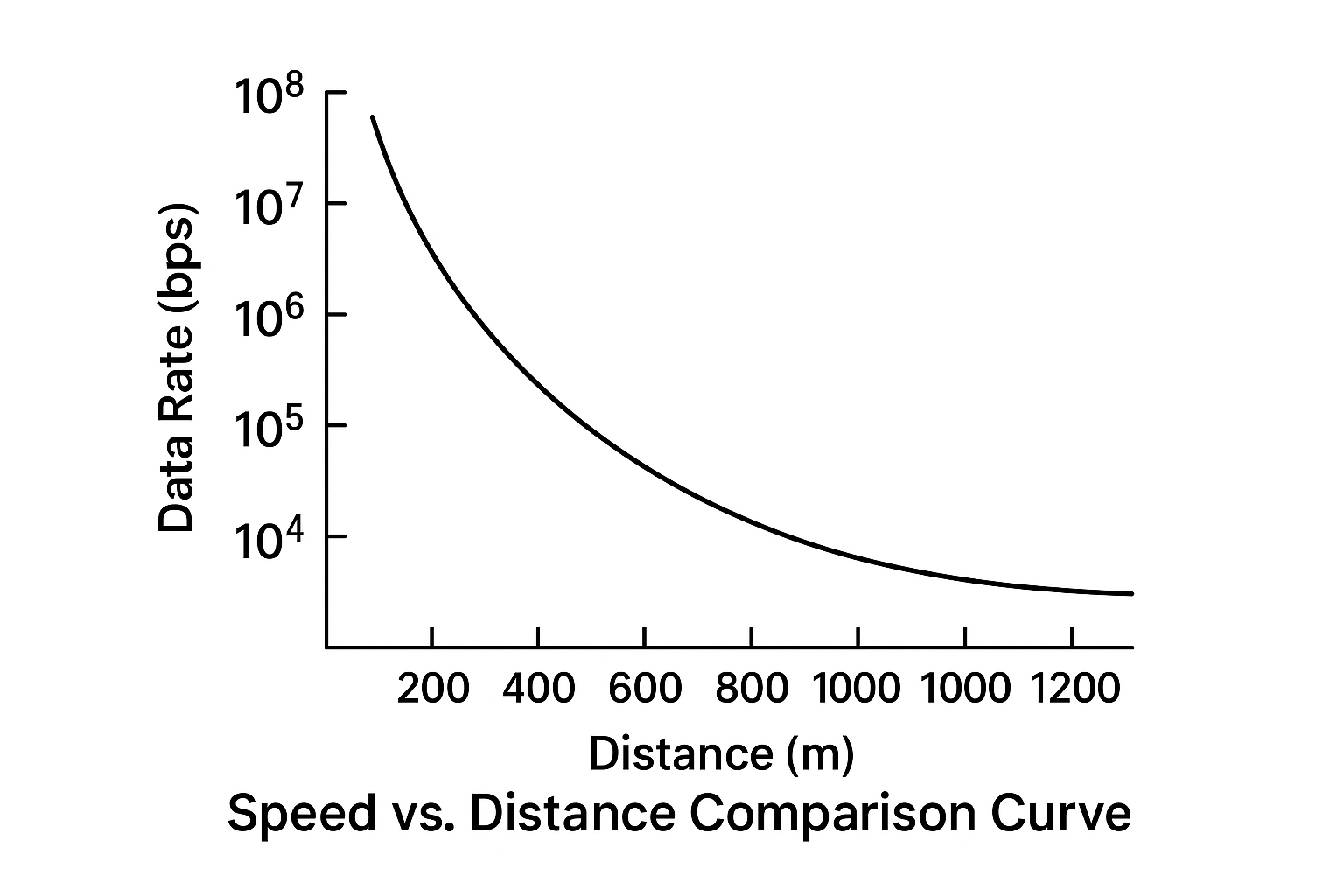

Noise Immunity & Distance

Two-Wire: Adequate in moderate environments.

Four-Wire: Superior in long-distance or noisy industrial settings.

4. Comparison Table

| Aspect | Two-Wire RS-485 | Four-Wire RS-485 |

|---|---|---|

| Communication Mode | Half-Duplex | Full-Duplex |

| Required Wires | 2 (A/B) | 4 (TX+, TX-, RX+, RX-) |

| Efficiency | Moderate (send/receive switching) | High (simultaneous TX/RX) |

| Noise Immunity | Standard | Stronger (long distance) |

| Installation | Simple | Complex |

| Cost | Low | Higher |

| Typical Use | Low-cost monitoring, small networks | High-speed, large-scale, noisy environments |

5. Case Studies

Case 1: Environmental Monitoring (Two-Wire RS-485)

A food processing plant required real-time monitoring of temperature and humidity across 20 sensors within a 100 m range.

A two-wire RS-485 bus was used.

Low-frequency polling was sufficient, with minimal cost and simple wiring.

Result: Stable operation with excellent cost-effectiveness.

Case 2: Automotive Production Line (Four-Wire RS-485)

A production line integrating multiple PLCs, VFDs, and robotic controllers required high-speed synchronization in a strong EMI environment.

Four-wire RS-485 provided full-duplex communication.

High reliability ensured smooth production cycles.

Result: Fast response, low error rate, stable operation.

6. Conclusion

Two-wire and four-wire RS-485 are complementary solutions rather than competitors.

Two-Wire: Best choice for small-scale, cost-sensitive, and low-speed applications.

Four-Wire: Ideal for real-time, large-scale, or interference-prone environments.

Selecting the right configuration saves both money and engineering effort, while ensuring system reliability and communication stability—a true reflection of engineering wisdom.