Introduction

In high-risk sectors such as chemical, petrochemical, and gas industries, the Safety Instrumented System (SIS) is the final layer of protection. However, design flaws, poor maintenance, and misuse of bypass functions can render this defense ineffective.

This document provides a standardized, lifecycle-based SIS inspection checklist, covering design, installation, operation, maintenance, assessment, and documentation. It is suitable for use in daily inspections, internal audits, or third-party safety assessments.

1. Design and Selection Compliance

1.1 Risk Analysis & SIL Determination

Conduct thorough HAZOP/LOPA studies to identify risk scenarios.

Match Safety Integrity Level (SIL) appropriately—high-risk processes require higher SIL.

Ensure documentation is reviewed and approved by experts or third parties.

1.2 Component Selection & Certification

Sensors, logic solvers, and actuators must hold valid SIL or TÜV certificates.

Must withstand the process environment (explosion-proof, corrosion/temperature resistance).

Prevent Common Cause Failures (CCF); redundant devices should not be from the same batch.

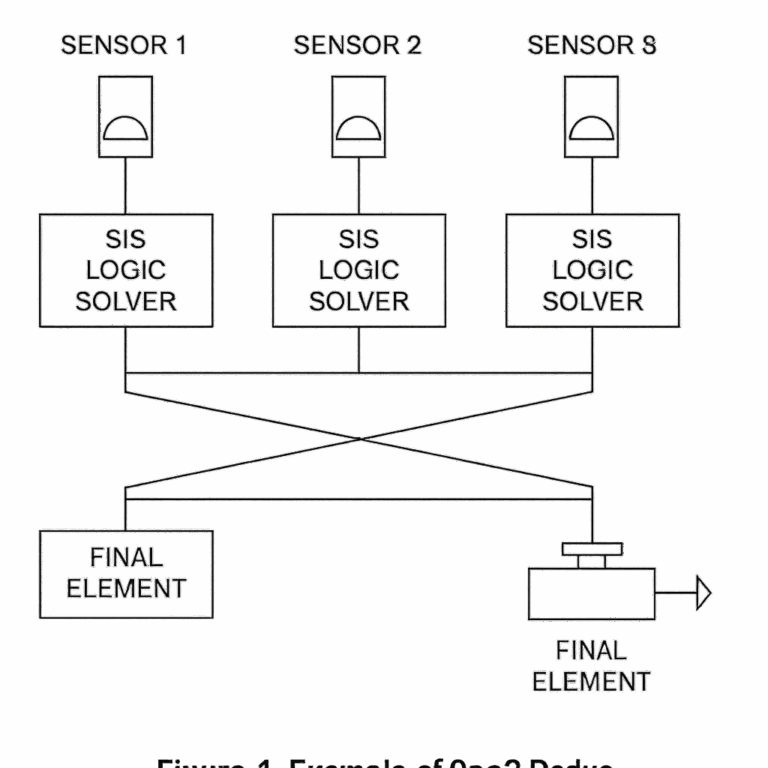

1.3 Architecture Design Integrity

Apply redundancy logic (e.g., 1oo2D, 2oo3).

Redundant configuration of sensors/actuators per SIL requirements.

Eliminate single-point failure risks.

2. Installation & Commissioning

2.1 Installation Quality

SIS wiring separated from DCS, with independent grounding (resistance ≤ 1 Ω).

Valves installed with sufficient space and smooth operation.

Sampling points must accurately reflect process conditions (avoid dead zones).

2.2 Commissioning Verification

Perform full-loop testing (Sensor → Logic Solver → Actuator).

Verify actuator response time meets design specs.

Simulate faults (e.g., disconnection, jamming) and record responses.

3. Operation & Maintenance

3.1 Periodic Testing

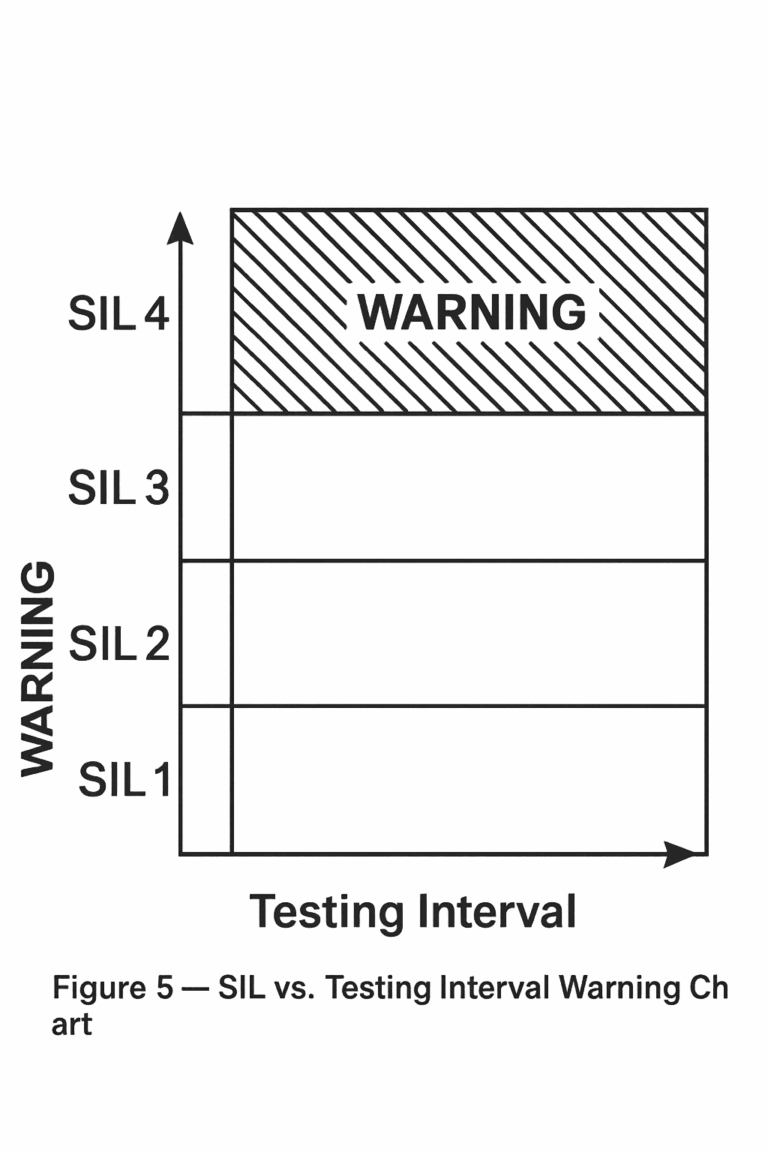

Testing intervals:

SIL 2: ≤ 1 year

SIL 3: ≤ 3 months

Tests include: sensor calibration, actuator response, logic function.

Use advanced methods such as PST (Partial Stroke Testing).

3.2 Fault Management

Establish clear fault response procedure: timestamp, symptom, root cause.

Prohibit operation under fault (e.g., sticking valves).

Use failure history to optimize maintenance planning.

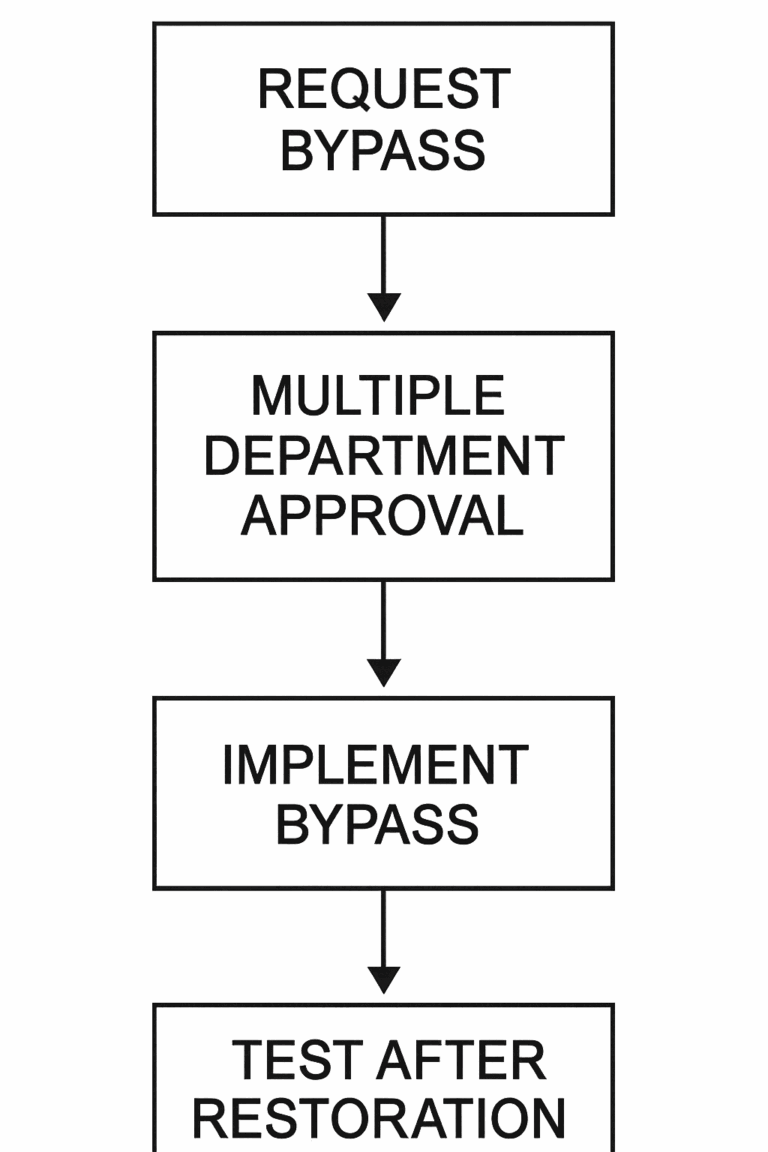

3.3 Bypass Management

Bypass must be approved by multiple departments.

Document the reason, duration, and contingency plan.

Post-bypass functionality test required.

4. Documentation & Traceability

Archive all documents: HAZOP, SIL verification, P&IDs, datasheets.

Maintain a device ledger with certification.

Keep test records, commissioning reports, failure logs, bypass forms.

Update documents after process changes or equipment upgrades.

5. Personnel Qualification & Training

Operators/technicians must be trained under IEC 61511 or equivalent.

Certification and regular retraining required.

Must distinguish real interlocks from false alarms and respond correctly.

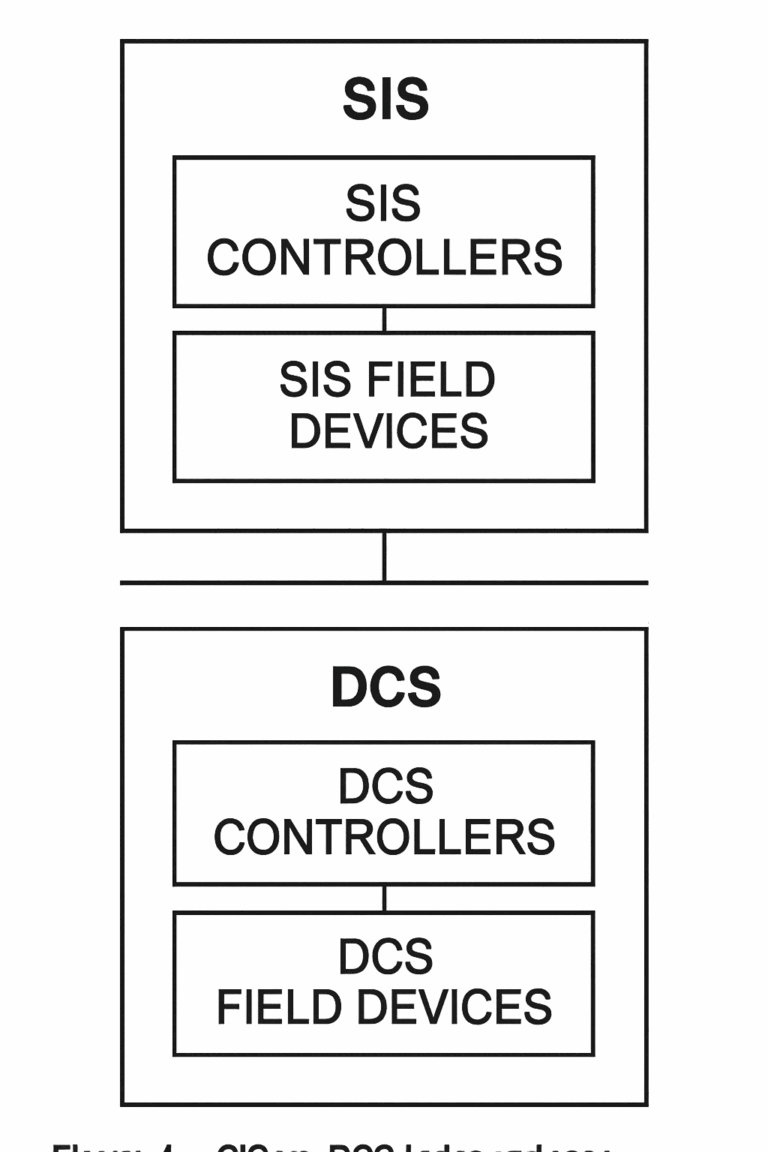

6. System Independence

SIS and DCS must be physically and logically independent.

Communication: unidirectional only.

Power supply: independent UPS; pneumatic: separate regulated air source.

7. Periodic Safety Assessment

Perform Functional Safety Assessment (FSA) every 3–5 years.

Cover process changes, aging equipment, maintenance deviations.

Use assessment results to improve SIS design and strategy.

8. Zero-Tolerance Violations

The following issues are strictly prohibited:

❌ Under-Spec SIL Levels (e.g., using SIL1 for high-risk scenarios)

❌ Overdue Testing (e.g., SIL3 not tested within 3 months)

❌ Bypass Abuse (unauthorized or prolonged bypass)

❌ Loss of Independence (SIS shares power or air with DCS)

9. Conclusion

The true value of SIS lies not in its existence, but in its readiness and reliability when needed. Embed this checklist into your safety management system to ensure every inspection is quantifiable, documented, and traceable.