Pressure loss—also known as pressure drop or head loss—is a critical concept in fluid engineering. It refers to the reduction in pressure as a fluid flows through a pipe, valve, fitting, or any other component in a system. Understanding and managing pressure loss is essential for the efficient and safe operation of pipelines, pumps, and control systems.

1. What Causes Pressure Loss?

Pressure loss in a piping system is primarily caused by two mechanisms:

a) Frictional Losses (Major Losses)

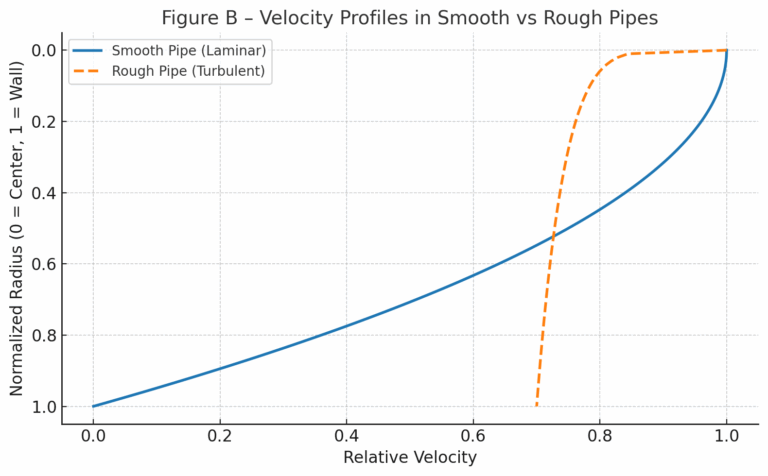

These occur due to the friction between the fluid and the internal wall of the pipe, as well as the internal friction within the fluid (viscosity). Factors affecting frictional losses include:

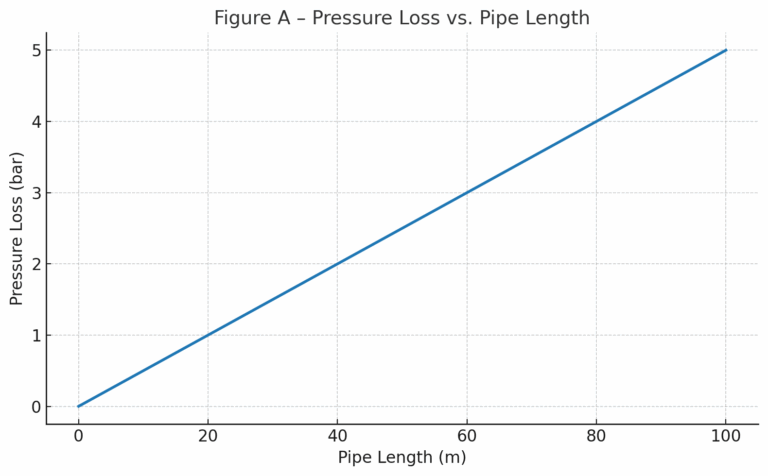

Pipe length (longer pipe → higher loss)

Pipe diameter (smaller diameter → higher velocity → higher loss)

Fluid velocity

Surface roughness of the pipe

Fluid viscosity and density

Darcy-Weisbach Formula:

hf=f⋅DL⋅2gv2

Where:

hf: head loss due to friction (m)

f: Darcy friction factor

L: pipe length (m)

D: pipe diameter (m)

v: fluid velocity (m/s)

g: gravitational acceleration (9.81 m/s²)

b) Local or Minor Losses

These result from flow disturbances caused by pipe fittings, bends, valves, expansions, contractions, or any sudden changes in direction or flow area. These cause turbulence and energy dissipation.

Minor Loss Formula:

hl=K⋅2gv2

Where:

hl: local head loss

K: loss coefficient (varies with component type)

2. Pressure Drop vs Head Loss

| Term | Unit | Context |

|---|---|---|

| Pressure Drop | Pa, bar, psi | Used in system design and instrumentation |

| Head Loss | meters of fluid column | Useful in pump sizing and fluid mechanics |

| Pressure Loss | Generic term | Can refer to either of the above |

Conversion Example:

Pressure loss of 1 bar ≈ 10.2 meters of water head

3. Why Pressure Loss Matters

Unchecked pressure loss can have serious consequences in industrial systems:

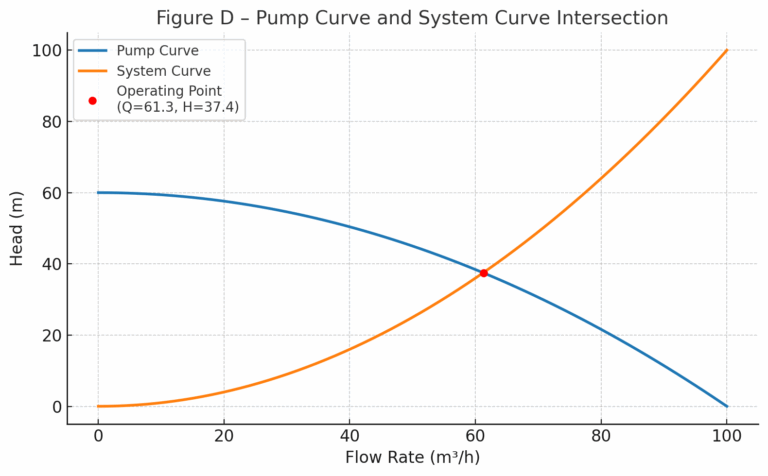

Increased Energy Consumption: Pumps and compressors must work harder to overcome losses.

Reduced Flow Rates: May result in poor process performance or unmet system demand.

Inaccurate Instrument Readings: Especially for flowmeters and transmitters.

Overdesign or Failure of Equipment: Components may be oversized or underperforming.

4. Strategies to Minimize Pressure Loss

| Engineering Measure | Effect |

|---|---|

| Increase pipe diameter | Reduces velocity, friction loss |

| Use smooth pipe materials | Reduces roughness |

| Minimize bends and fittings | Reduces local losses |

| Use gradual transitions | Avoids abrupt turbulence |

| Optimize flow rate | Balances system pressure and flow needs |

5. Application Scenarios

| Industry | Application | Pressure Loss Considerations |

|---|---|---|

| Water Treatment | Long-distance water transport | Use large-diameter HDPE pipes |

| Chemical Plants | Process flow control | Balance valve selection with flowrate |

| HVAC | Air duct design | Minimize elbows and resistance |

| Oil & Gas | Gas distribution | Account for compressibility and density changes |

Conclusion

Understanding and managing pressure loss is essential to efficient piping system design. Whether transporting water, steam, oil, or chemicals, engineers must account for both frictional and local losses to ensure performance, energy efficiency, and safety. Tools such as the Darcy-Weisbach equation, empirical K-values for fittings, and system curve simulations are invaluable in modern fluid engineering.