1. Scope

This guide standardizes how to design, integrate, retrofit, and maintain a Gas Detection System (GDS) so that leak detection, alarm, and emergency annunciation remain available regardless of the state of the Basic Process Control System (BPCS) or Safety Instrumented System (SIS).

2. Normative references (baseline)

National design standard for flammable/toxic gas detection and alarm in petrochemical facilities (e.g., GB/T 50493).

Project HSE plan, company Engineering Standards (ES), and local fire code.

Note: Where international standards (e.g., IEC, NFPA) are adopted, align alarm philosophy and device selection but keep GDS independence per this guide.

3. Definitions & abbreviations

GDS — Gas Detection System (flammable/toxic).

BPCS — Basic Process Control System (e.g., DCS/PLC controlling processes).

SIS — Safety Instrumented System.

FAS — Fire Alarm System / Fire & Gas Panel in the fire control room.

CCR — Central Control Room.

UPS — Uninterruptible Power Supply (industrial).

4. Design principles (must‑have)

Independence: The GDS shall be independent from BPCS and SIS in logic, power, and essential annunciation, so it functions during BPCS shutdowns, maintenance, or failures.

Priority: For co‑located hazards, toxic gas alarm priority shall not be lower than flammable gas alarms.

Detector segregation for SIS inputs: If leak signals are also used by SIS (e.g., for automatic actions), provide dedicated detectors and dedicated signal paths to SIS.

Mandatory annunciation to fire control: At least second‑level flammable gas alarms and GDS controller fault shall be annunciated to the fire control room (FAS).

Operator awareness in CCR: Provide distinct audible/visual alarms (different tone from process alarms) in the CCR operating area.

5. System architecture

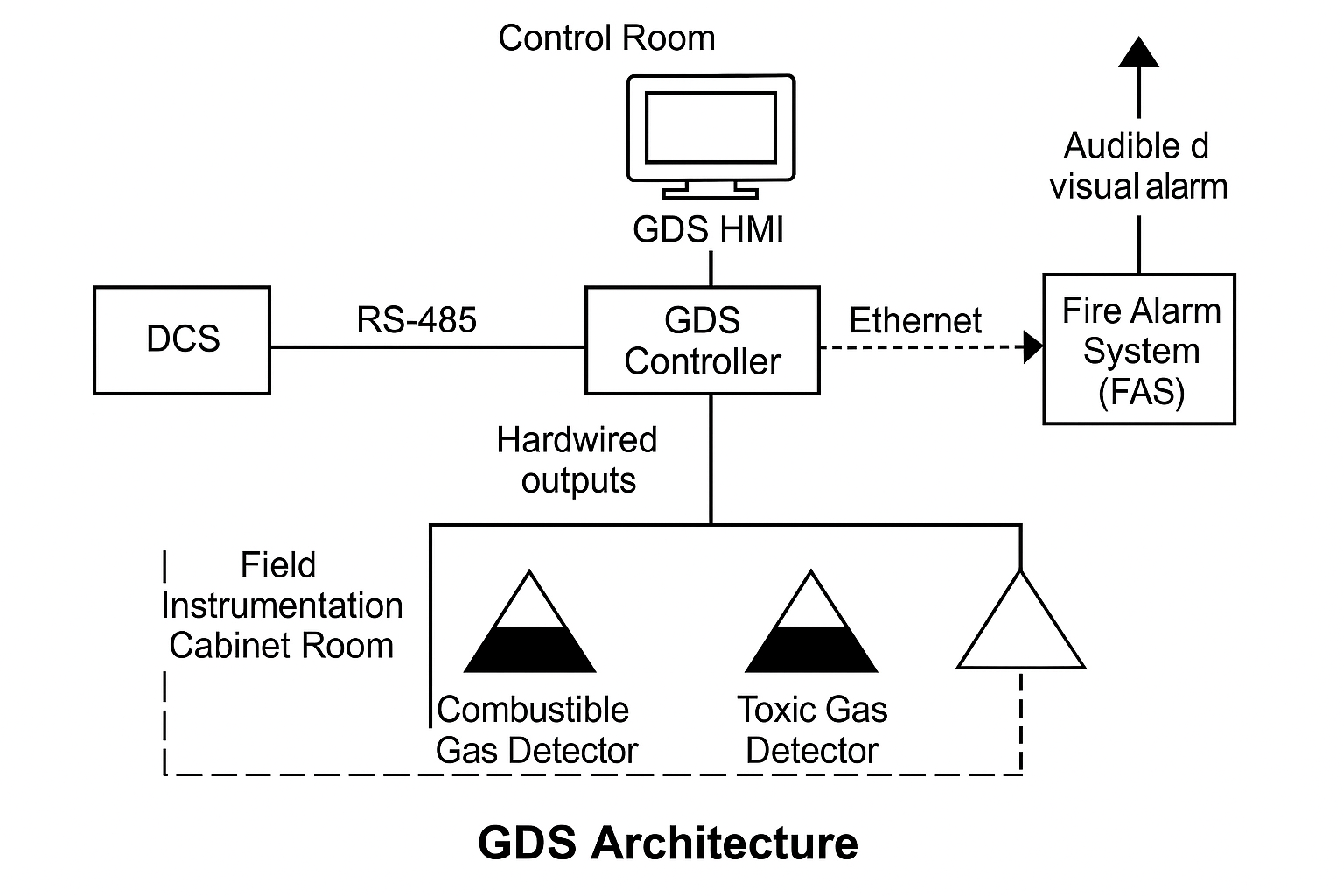

5.1 New plants / major revamps (recommended architecture)

Controller: Independent controller (dedicated DCS controller, PLC, or dedicated gas controller). Use redundant CPU, power, I/O, and network where feasible.

Physical segregation:

Mount GDS controller and Layer‑1 network gear inside the field instrument cabinet room adjacent to the unit.

Mount Layer‑2 network gear in the CCR equipment room.

HMI/annunciation: Provide a dedicated GDS HMI/operator station in CCR with distinctive sound for toxic/flammable gas and fault.

Hardwired interfaces:

Hardwire Level‑2 flammable gas and GDS fault outputs to FAS in the same field instrument room.

Provide RS‑485/industrial Ethernet links from GDS to BPCS for indication and recording only (no essential dependence).

CCR local protection: Install an independent GDS controller (or I/O segment) dedicated to CCR area detection.

Power: Dual 24 VDC redundant supplies from industrial UPS, with fused distribution to each detector loop.

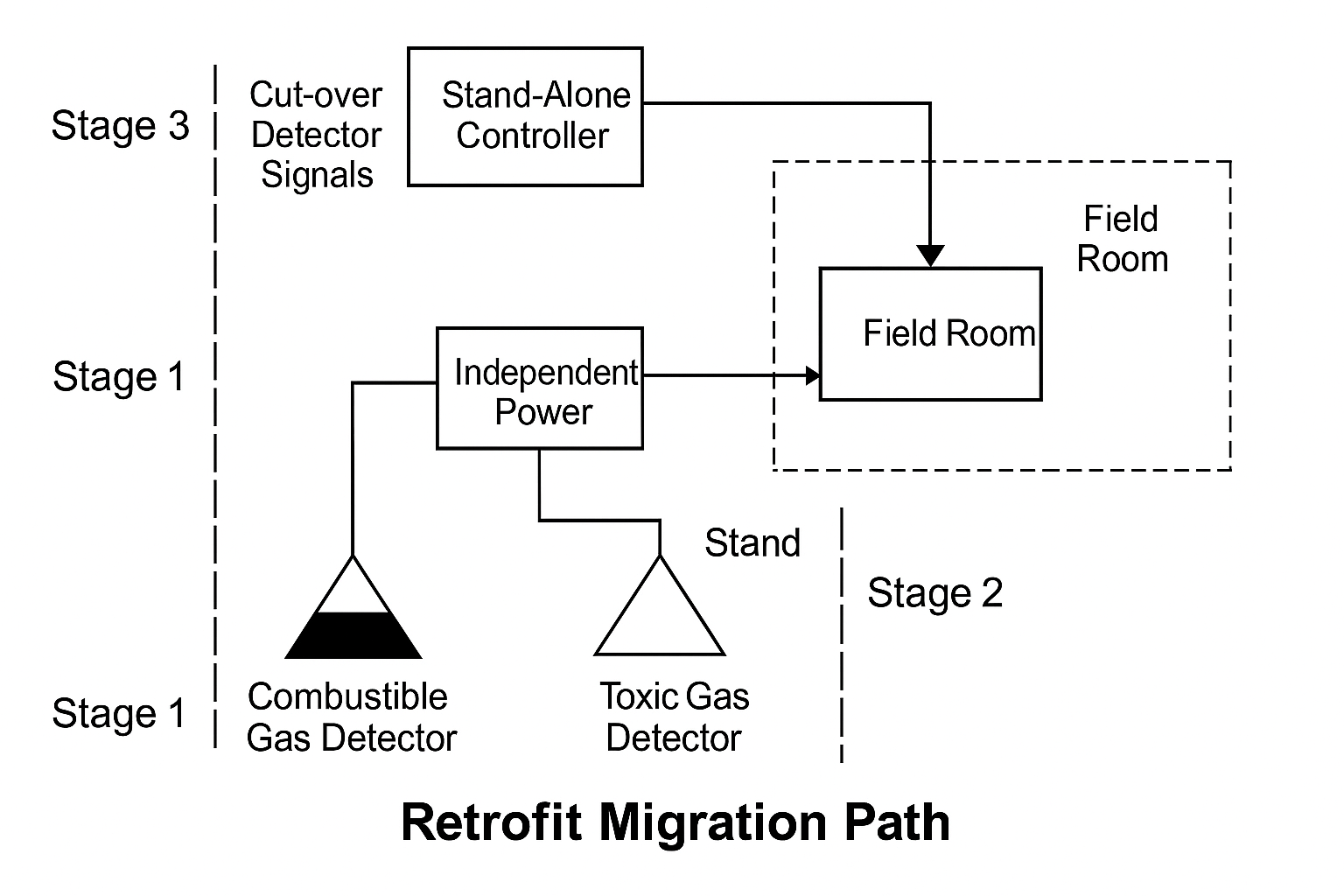

5.2 Existing plants (brownfield) — pragmatic retrofit path

Do not disrupt a stable BPCS unnecessarily. If detectors are currently terminated on BPCS I/O, first:

Move detector power to a separate 24 VDC/UPS with independent fused distribution.

Add a dedicated GDS HMI/annunciator in CCR with a distinct alarm tone.

Keep the legacy BPCS indication temporarily; plan to migrate to an independent GDS controller during the next major turnaround.

Long‑term target: Independent GDS controller with hardwired outputs to FAS and a monitoring link to BPCS.

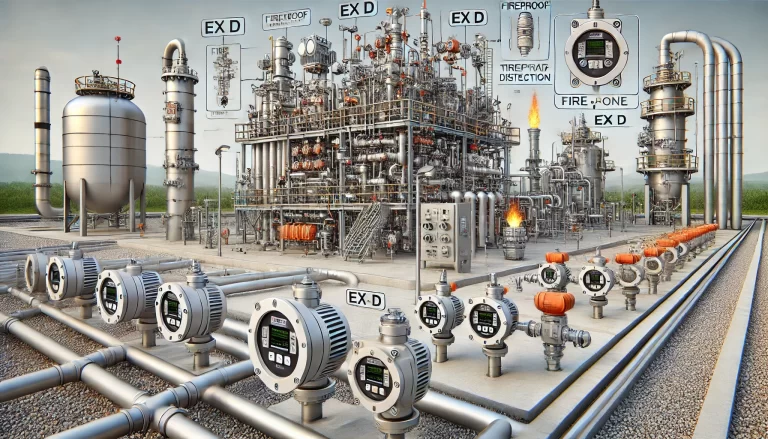

6. Detector selection & placement

Detector types: flammable (catalytic/IR), toxic (electrochemical/IR), open‑path (IR/UV). Select per gas type and environment.

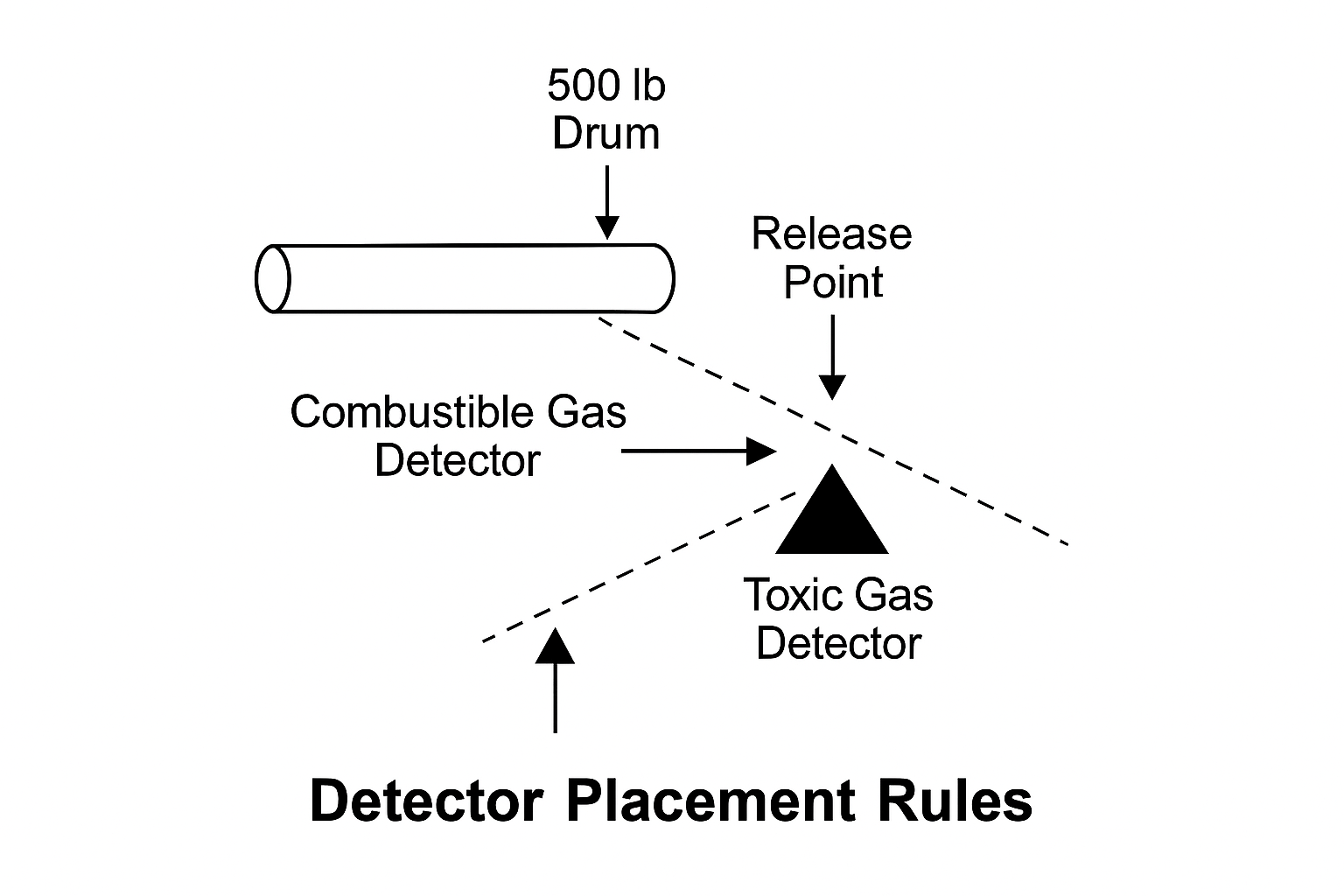

Placement principles:

Consider space form (closed / semi‑closed / open), gas density vs air, prevailing wind, min/max wind speed, obstacles, distance to credible release sources.

Provide additional coverage in compressor houses, pump rooms, analyzer shelters, silos—and install beacons/sounders at exits/entrances driven by the GDS.

Quantity optimization: “More is not always better”—perform dispersion‑aware coverage assessment; avoid blind spots and false alarms.

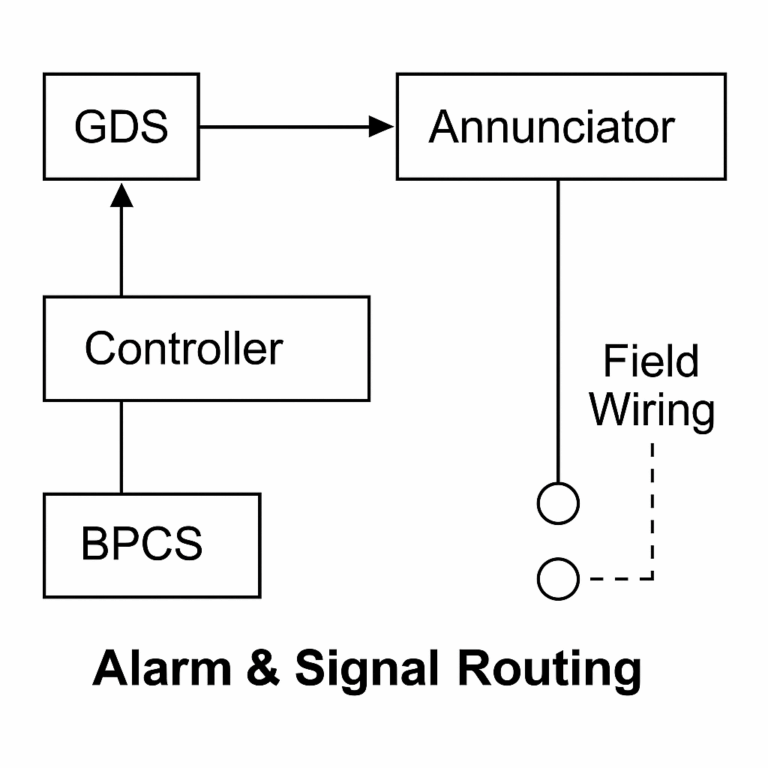

7. Alarm philosophy & routing

Alarm levels: Define project‑specific thresholds and annunciation (e.g., L1/L2 for flammable, low/high for toxic) with toxic priority not lower than flammable.

Routing:

Hardwire: L2 flammable + GDS fault → FAS (fire control room).

Indication/recording: GDS → BPCS via RS‑485/Ethernet.

SIS use: If leak signals trigger SIS functions, use independent detectors and dedicated inputs to SIS.

8. Power supply & availability

Supply class: Treat GDS as Category‑1/critical load; back up via UPS sized for the hold‑up time defined in the HSE plan.

Distribution: Redundant 24 VDC with fused terminal blocks or smart power distributors; isolate detector circuits to avoid common‑cause failures.

Survivability: Ensure GDS availability during BPCS outages, CCR maintenance, and partial unit shutdowns.

9. Cybersecurity & segregation

Separate GDS network from plant BPCS/SIS networks; use one‑way data diodes or read‑only links for plant historian if required.

Restrict write access from BPCS to GDS (monitoring only).

10. Commissioning, testing & maintenance

Factory acceptance (FAT): I/O mapping, redundancy failover, alarm routing, FAS hardwired checks.

Site acceptance (SAT): Functional test with bump gas, field beacons/sounders, CCR annunciation, FAS receipt.

Routine: Bump tests per criticality, calibration per sensor technology and environment; verify alarm tones and CCR displays after any software changes.

11. Documentation deliverables

Architecture drawings (P&IDs, network, I/O lists), alarm setpoint list, cause‑&‑effect matrix (GDS ↔ FAS/SIS/BPCS), power SLD, detector layout drawings with coverage rationale, test procedures and records.