Executive Summary

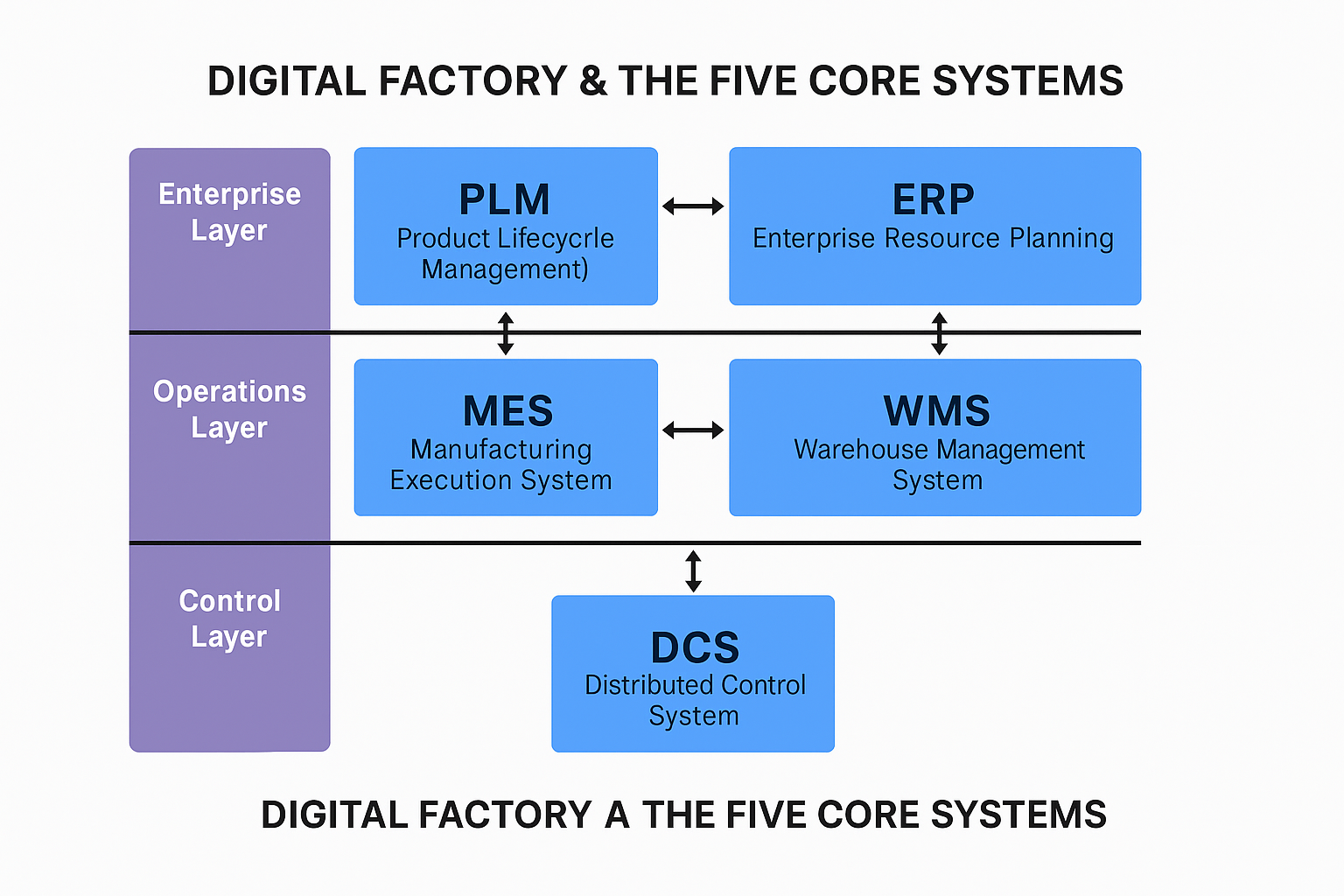

A Digital Factory uses end-to-end lifecycle data and model-based simulation to mirror, evaluate, and optimize production in a virtual environment—then extends that capability across the entire product lifecycle. The aim is not full automation replacing people; it is augmenting people with real-time data, precise guidance, and intelligent analytics to raise throughput, quality, and asset utilization while reducing waste. The heart of the approach is deep, MOM-guided integration of five enterprise systems: PLM, ERP, MES, WMS, and DCS.

1) What a Digital Factory Is (and Isn’t)

Definition. A virtualized manufacturing paradigm that relies on lifecycle data to simulate, assess, and optimize production, bridging the gap between design and actual manufacturing.

Human-centered. A Digital Factory does not equal “lights-out” automation; it empowers operators and engineers with better decisions and faster execution.

Business value. In cost- and efficiency-focused environments, process optimization and higher OEE increase capacity without proportional headcount growth.

2) MOM-Guided Architecture Overview

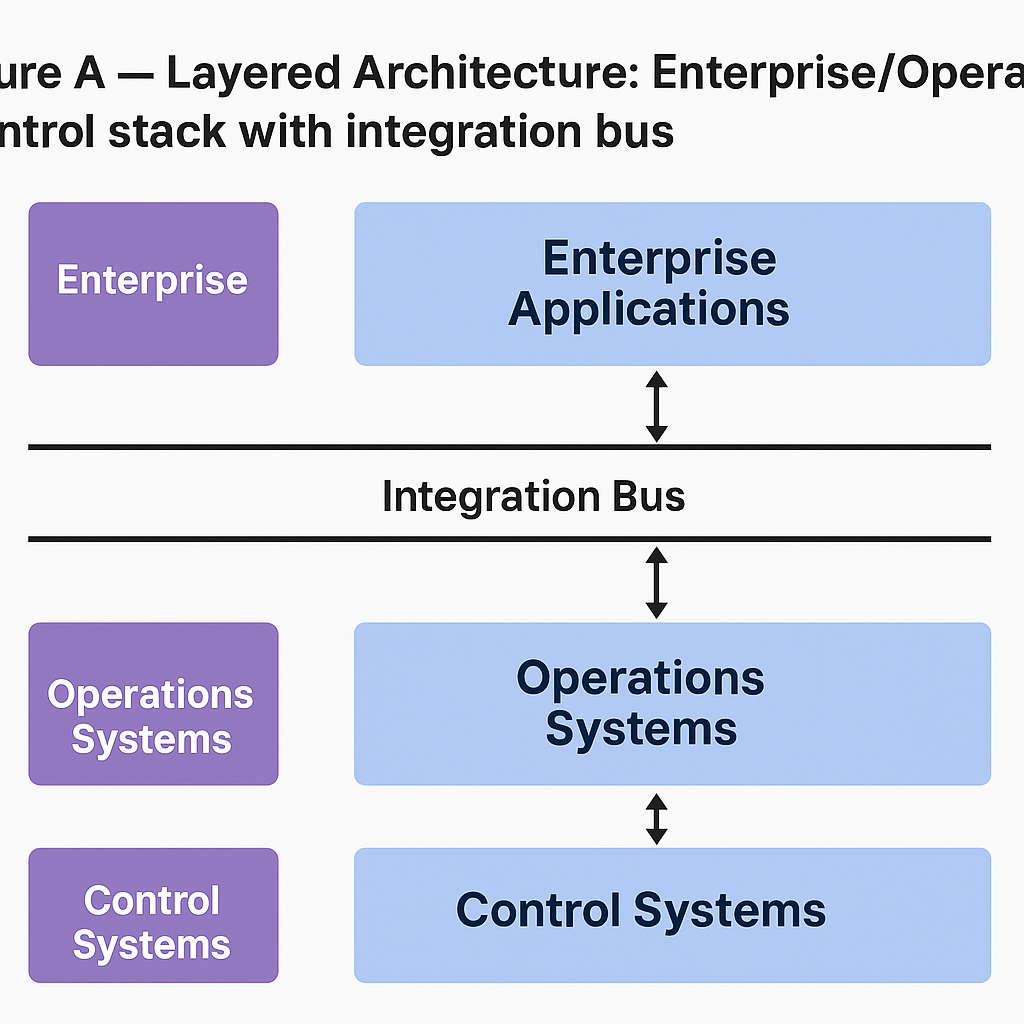

Manufacturing Operations Management (MOM) defines clear process and data boundaries between systems and ensures seamless flows across planning, quality, maintenance, and inventory.

Figure A — Layered Architecture (placeholder)

Enterprise layer: PLM ↔ ERP

Operations layer: MES (with APS/QMS) ↔ WMS

Control layer: SCADA/PLC/DCS → MES

Integration: iPaaS/middleware, message bus, APIs (REST), industrial protocols (OPC UA/MQTT)

3) Core Systems—Roles & Boundaries

3.1 PLM — Product Lifecycle Management

Role. Governs concept-to-retirement product data, including structures and change control.

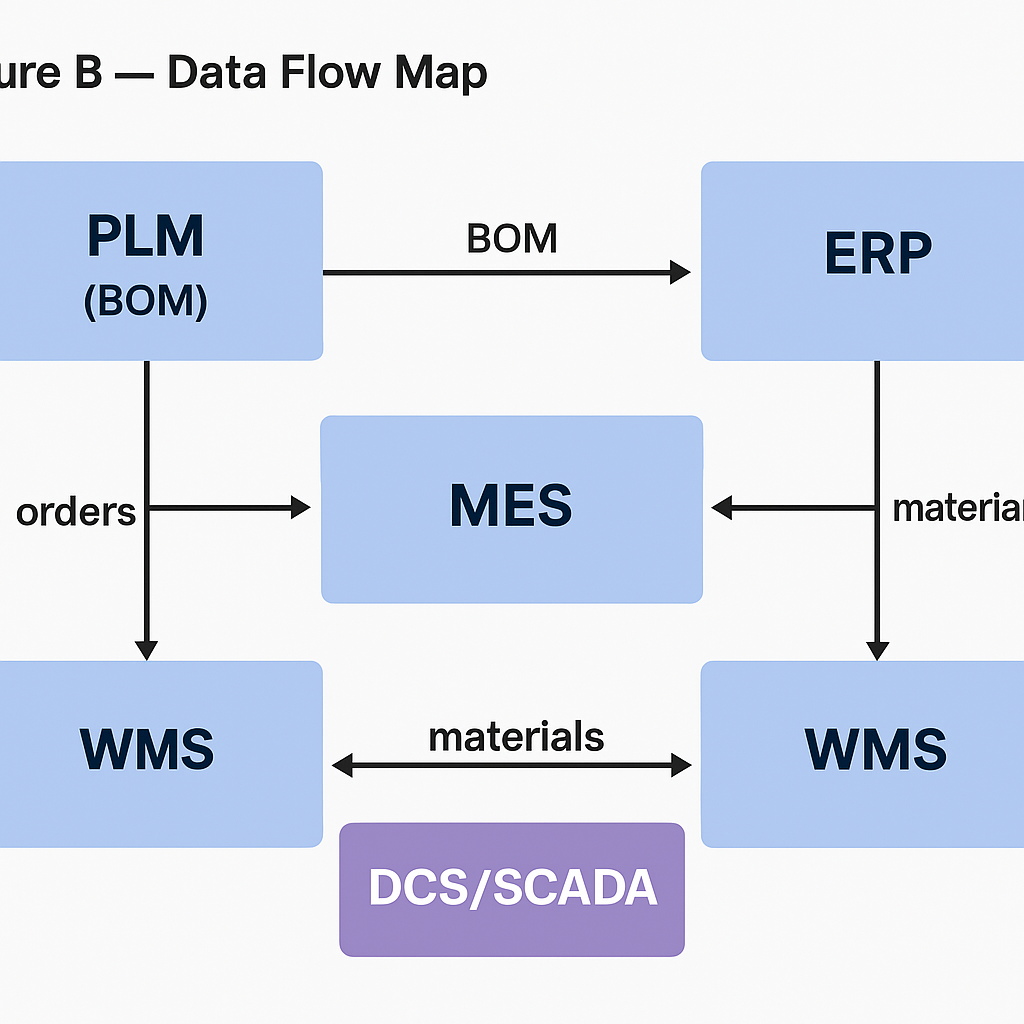

Key outputs. Engineering BOM (eBOM) and manufacturing BOM/process data handed to ERP/MES; design constraints passed down to control systems.

3.2 ERP — Enterprise Resource Planning

Role. Company-wide finance, procurement, sales, supply chain, and inventory accounting.

Integration. Receives BOM from PLM; exchanges plans, orders, confirmations, and cost/stock data with MES/WMS.

3.3 MES — Manufacturing Execution System

Role. The shop-floor brain: dispatching, work instructions, routing, genealogy/traceability, quality data capture, labor, and performance.

Up/Down links. Upstream to ERP (orders/confirmations) and downstream to PLC/DCS/SCADA for real-time data and interlocks.

3.4 WMS — Warehouse Management System

Role. Receipts, put-away, picking, kitting, WIP and finished-goods inventory, locations, and logistics.

Integration. Tightly coupled to ERP for valuation and to MES for line-side material availability and tracking.

3.5 DCS — Distributed Control System

Role. Process-level control and HMI/alarms; executes control strategies and streams time-series data to upper layers.

Integration. Provides the data foundation for MES and SCADA; forms the closed loop with work orders and quality rules.

4) Extended Solution Components

APS (Advanced Planning & Scheduling): Fine-grained finite-capacity scheduling; often embedded in MES or deployed standalone.

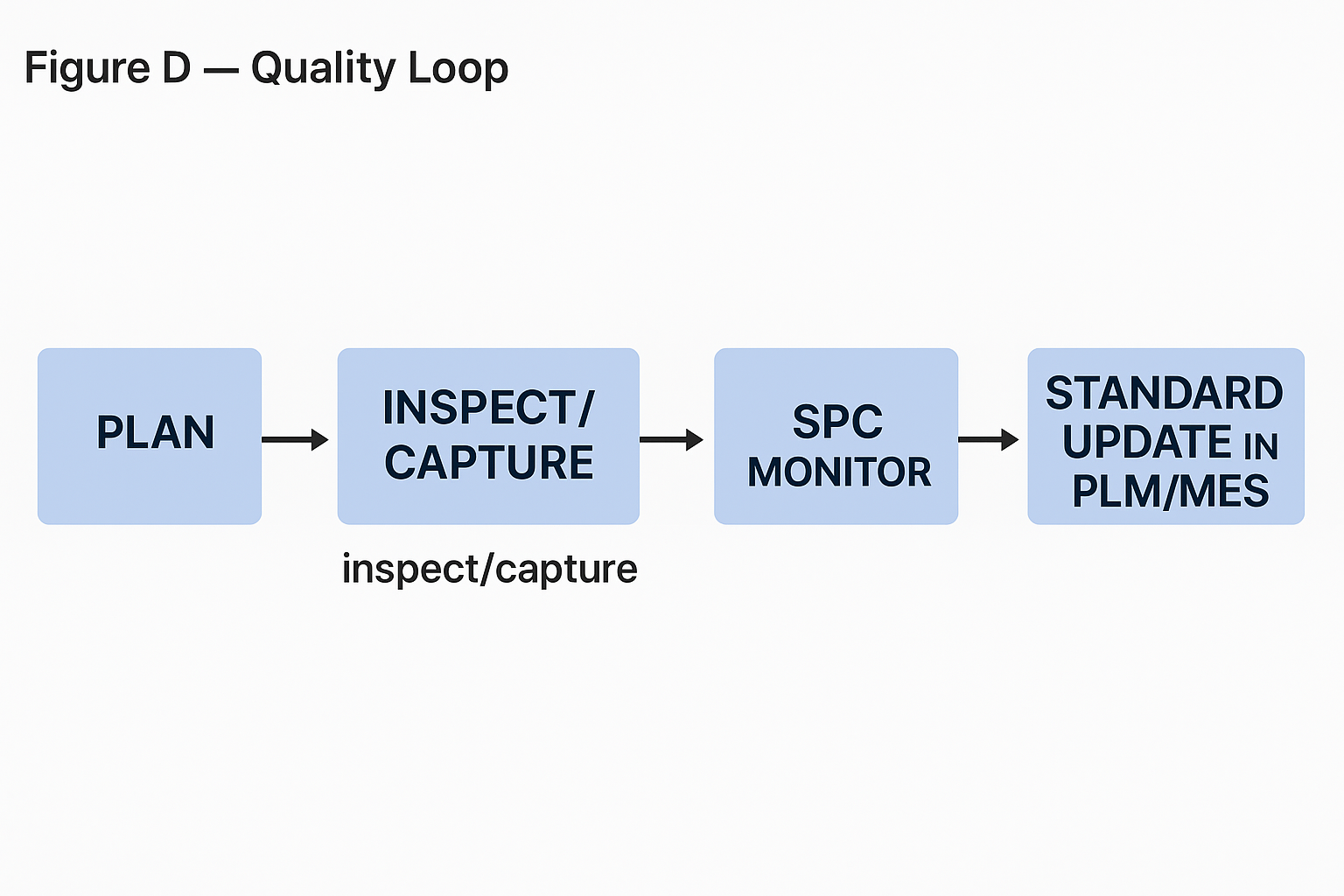

QMS (Quality Management System): End-to-end quality plans, NC/CAPA, SPC—best integrated with MES for one source of truth.

SCADA: Bridge from equipment/PLC/DCS to MES for data acquisition and line supervision (especially in discrete/line contexts).

Integrated Automation Stack (e.g., TIA-style): Unified engineering and communication backbone.

5) Data Model & Master Data (minimal, but sufficient)

Products: Item master; eBOM (PLM), mBOM/routing (MES/ERP).

Process: Operations, parameters, control limits, recipes.

Resources: Equipment, cells, and tooling with capabilities and calendars.

Materials & Inventory: Lots/serials, locations, statuses (QA hold, quarantine, etc.).

Personnel: Skills, qualifications, shift assignments.

6) Integration Patterns & Standards

Application integration: REST/GraphQL APIs, iPaaS/middleware, event buses (pub/sub).

Industrial data: OPC UA, MQTT, Modbus/TCP; edge gateways for protocol bridging.

Information models: ISA-95/88 alignment; B2MML for structured exchanges.

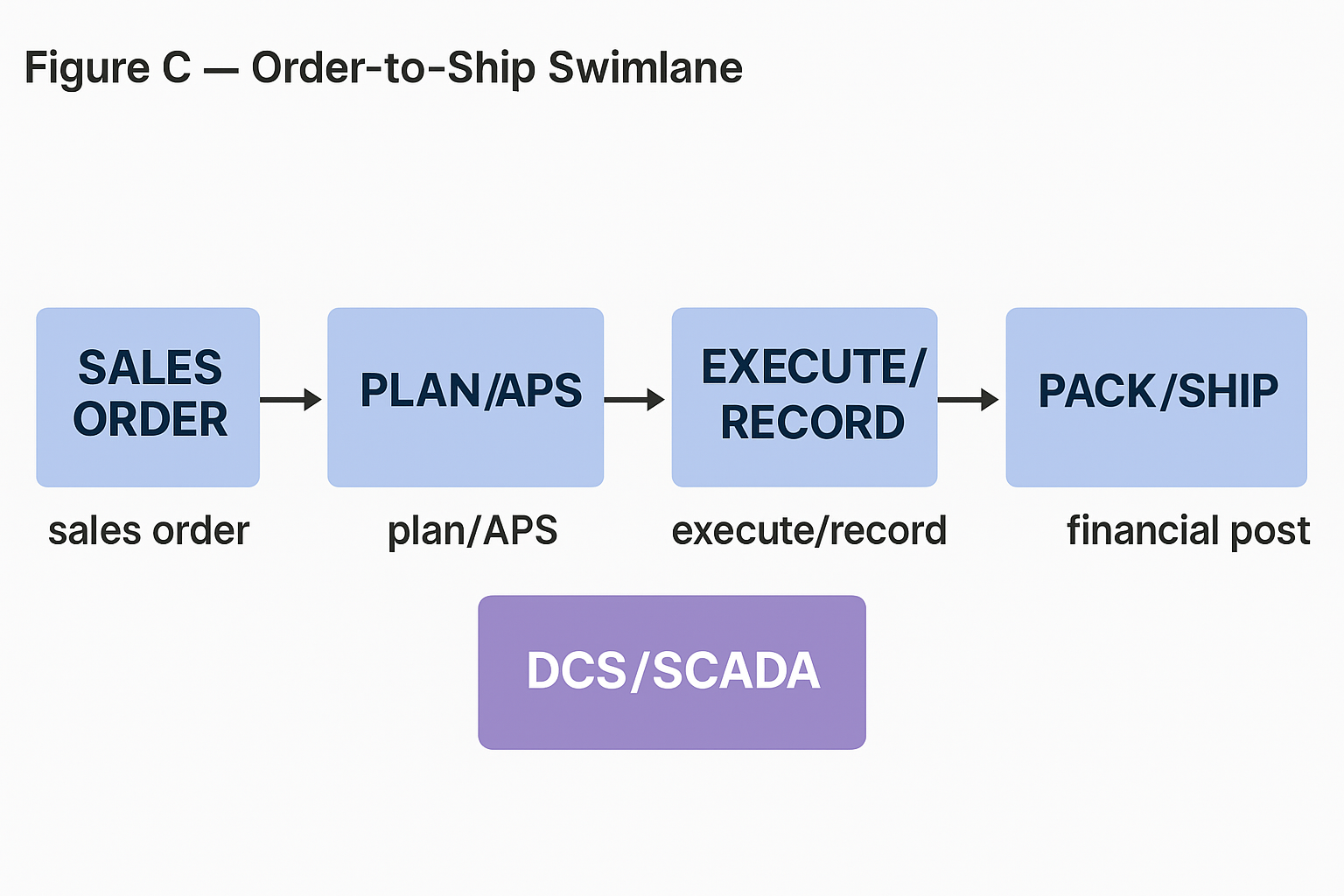

Key flows: PLM→ERP (BOM); ERP→MES (orders/plan); MES↔WMS (material moves); DCS/SCADA→MES (process & alarms).

7) Shop-Floor Connectivity & Control

From control to context. DCS/SCADA/PLC signals are contextualized by MES (order, recipe, operator, tooling) to enable traceability and analytics.

Closed-loop. Quality rules and work instructions descend from MES; interlocks and setpoints are enforced at DCS/PLC level.

8) KPIs and Value Realization

Operations: OEE, throughput, WIP turns, schedule adherence, changeover time.

Quality: FPY, DPPM, SPC violations, genealogy coverage.

Supply chain: Inventory accuracy, OTIF/OTD, warehouse cycle time.

Financials: Cost per unit, variance vs. standard cost.

9) Implementation Roadmap (Phased, low-risk)

Discover & design: Process mapping, boundary definition, data contracts, KPIs.

Pilot line/area: MES core + WMS interfaces + minimal ERP/PLM handoffs.

Scale & harden: APS/QMS enablement, SCADA/DCS integration, data lake.

Optimize: Advanced analytics, predictive maintenance, closed-loop quality.

10) Governance, Security, and Compliance

MOM-based governance: Change control across PLM/ERP/MES; master-data ownership and RACI.

Cybersecurity: Network zones, least privilege, patch cadence; align to IEC 62443 principles.

Validation & auditability: Electronic records, e-signatures, and traceability where required.