0) Summary (for busy engineers)

Common symptoms in large‑bore steam service: zero drifting, negative oscillation, large bias.

Root causes: poor straight‑run, wrong cross‑section position, two‑phase effects, impulse/condensate handling, orientation error.

With correct siting, impulse design, and anti‑interference measures, ±2.5% is achievable in real plants.

1) Straight‑Run Requirements

Goal: let the velocity profile re‑develop into a stable, near‑axisymmetric shape before the APT.

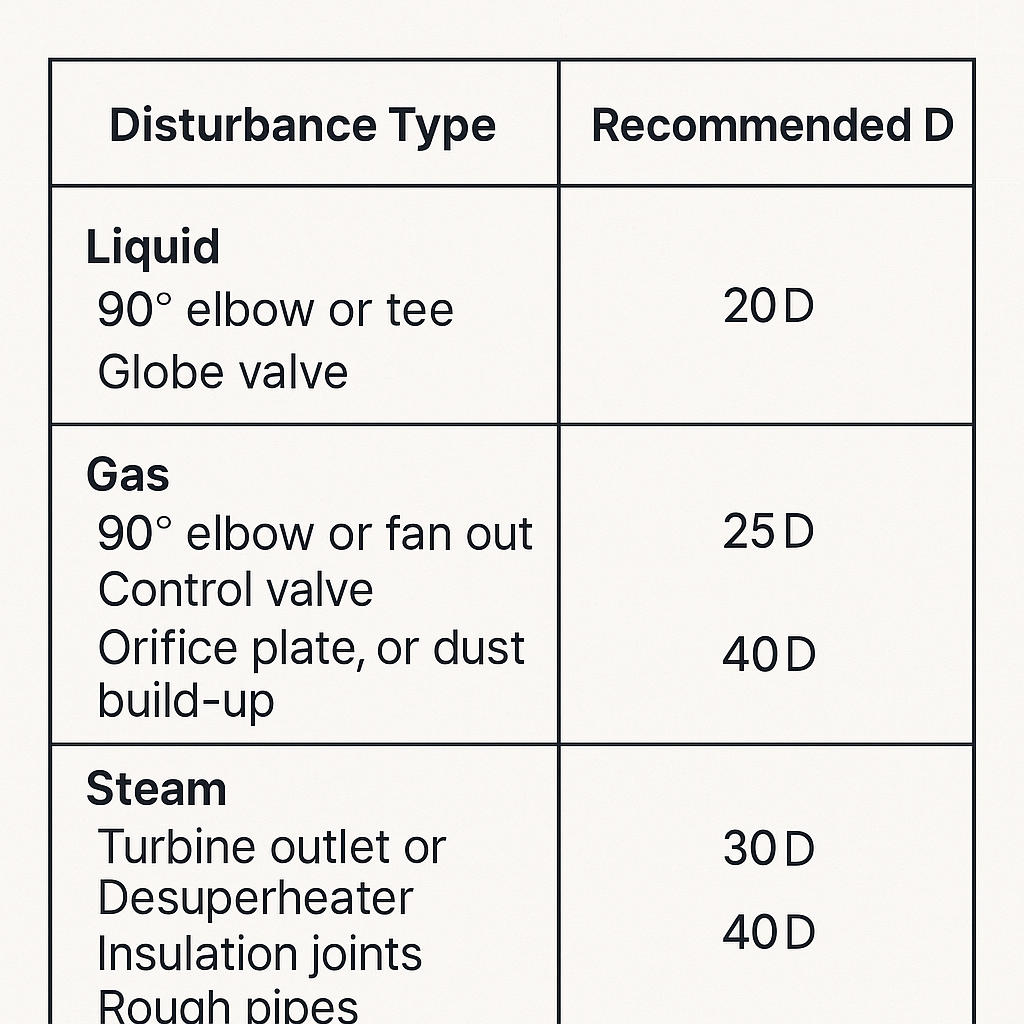

1.1 General baseline (single‑phase, clean piping)

Upstream ≥ 10D

Downstream ≥ 5D

1.2 Adjust by disturbance severity (examples)

90° elbow or tee just upstream → ≥ 20D

Ball/globe/control valve just upstream → ≥ 30D–40D

Fan/turbine/DMR (desuperheater) outlet → ≥ 30D–40D (steam)

For dusty gas or slurry‑like liquids, extend upstream to ≥ 40D–50D and downstream ≥ 10D–30D as needed.

Small bore (D < 100 mm): add ~50% to the numbers above.

If space is tight: consider paired, symmetric elbows to partially cancel swirl, then keep ≥ 10D (single‑phase only).

Field tip: old, rough pipe or poor liner joints behave like extra disturbances—treat as +10D equivalent.

2) Cross‑Section Positioning (horizontal runs)

Principle: avoid phase segregation regions so all sensing ports see a representative bulk phase.

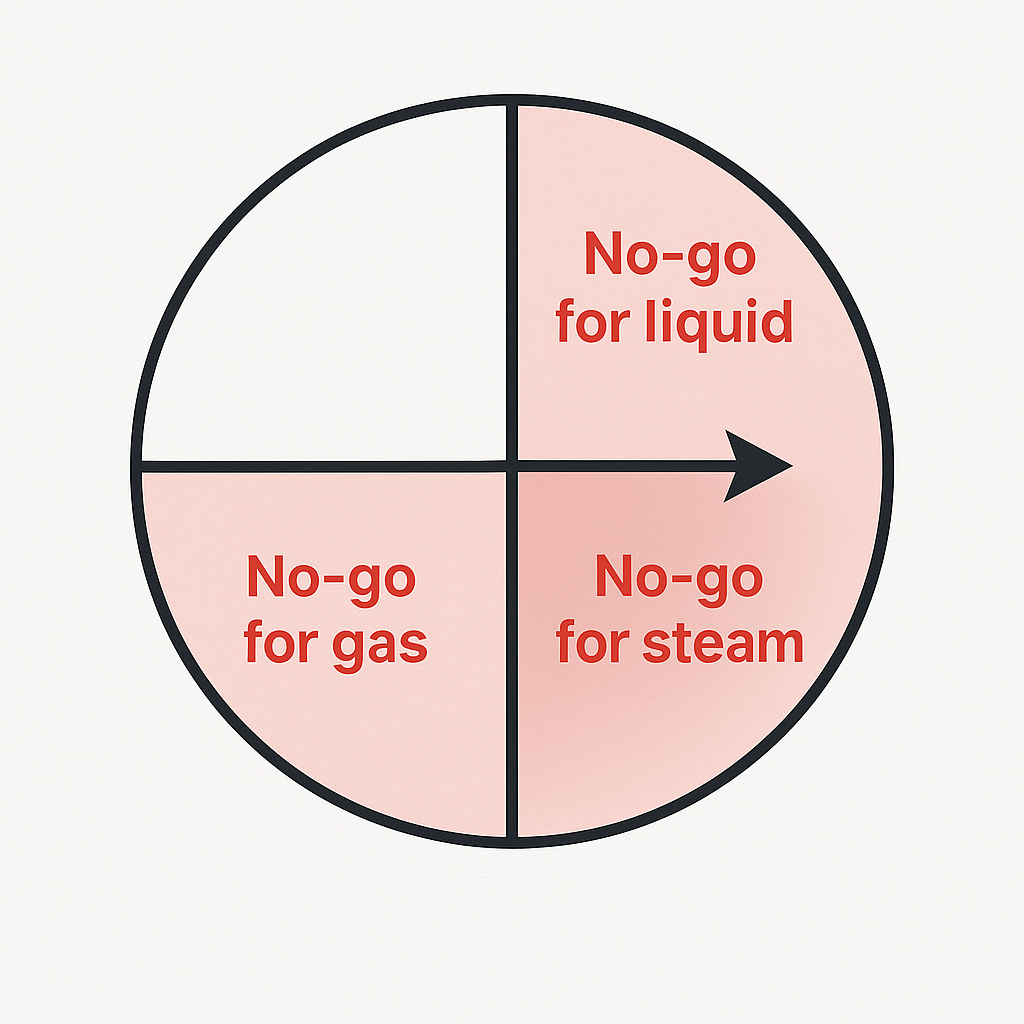

2.1 Liquids

Place the probe within 0°–45° below the horizontal centerline (i.e., just below midline).

Avoid top (gas pockets) and bottom (sediment) zones.

2.2 Gases

Place the probe within 0°–45° above the horizontal centerline.

Avoid bottom zone where condensate/dust accumulates.

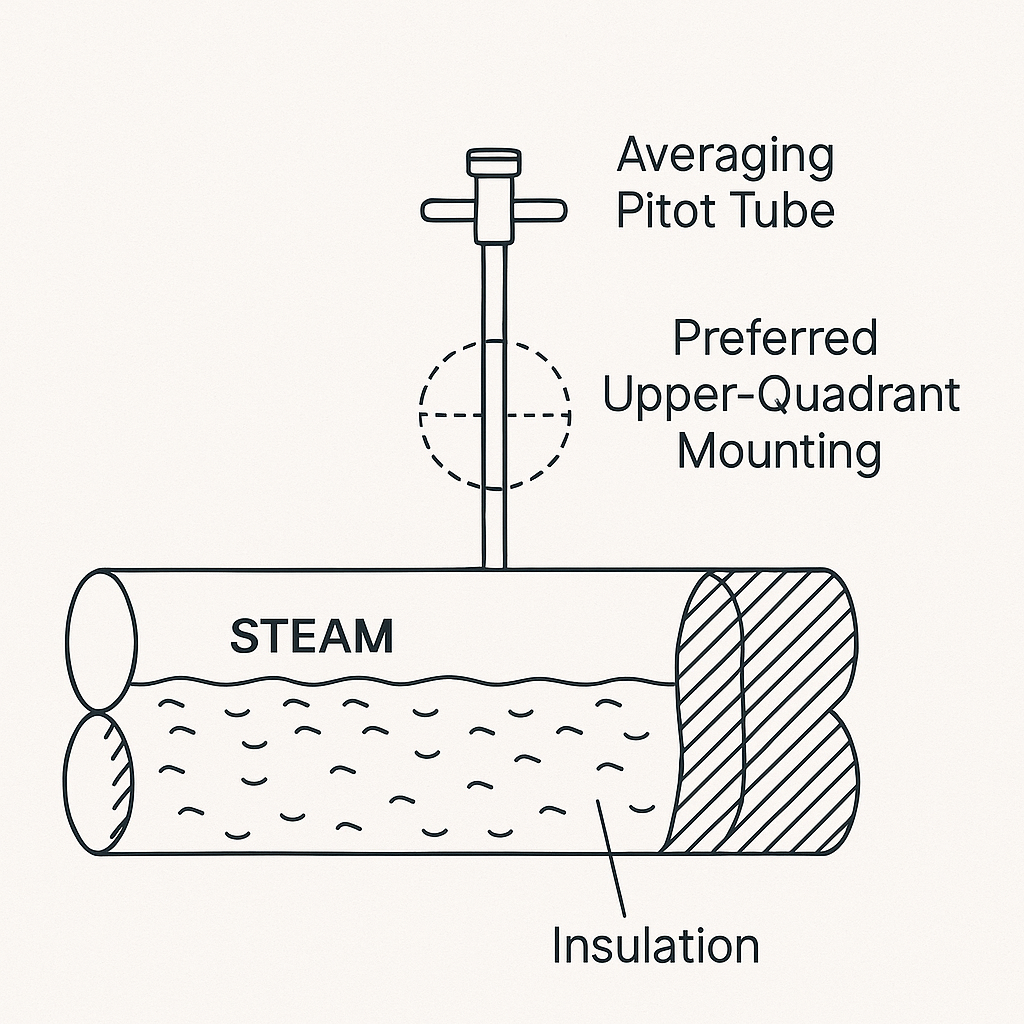

2.3 Steam (esp. wet steam)

Treat as two‑phase. Do not mount in the bottom quadrant (90°–180°) where liquid film/droplets pass; this causes DP bias and noise.

Prefer the upper quadrant; use insulation and high‑temp isolation practices.

Orientation check: verify insertion angle with a laser alignment tool; ±2° max error. High/low ports must face true flow direction.

3) Impulse/Take‑off Design & Anti‑Interference

Use short, direct, equal‑length runs for high/low lines. Minimize vertical loops.

For dirty liquids, specify anti‑plugging ports (chamfered or conical) and purge fittings; schedule periodic inert‑gas purges.

Steam: avoid U‑loops and condensate pots that trap liquid and drift the zero. Keep lines sloped back to the process; provide heat shielding and weather hoods outdoors.

Consider capillary with fill fluid for long runs or high vibration.

4) Materials & Environment

Default 316L for wetted parts in mildly corrosive media; upgrade as required.

Outdoor installs: fit rain/sun hood, maintain insulation integrity, protect capillaries.

5) Commissioning Checklist (one‑page)

Tag & range match P&ID; density/pressure/temperature data confirmed.

Upstream/Downstream straight runs measured and recorded.

Insertion depth and port orientation verified (±2°).

Impulse lines: equal length, slope toward process, no low pockets.

Purge/vents tested; zero stability check at no‑flow.

Damping/filter set to suppress high‑frequency noise; log baseline DP at 3–5 stable loads.

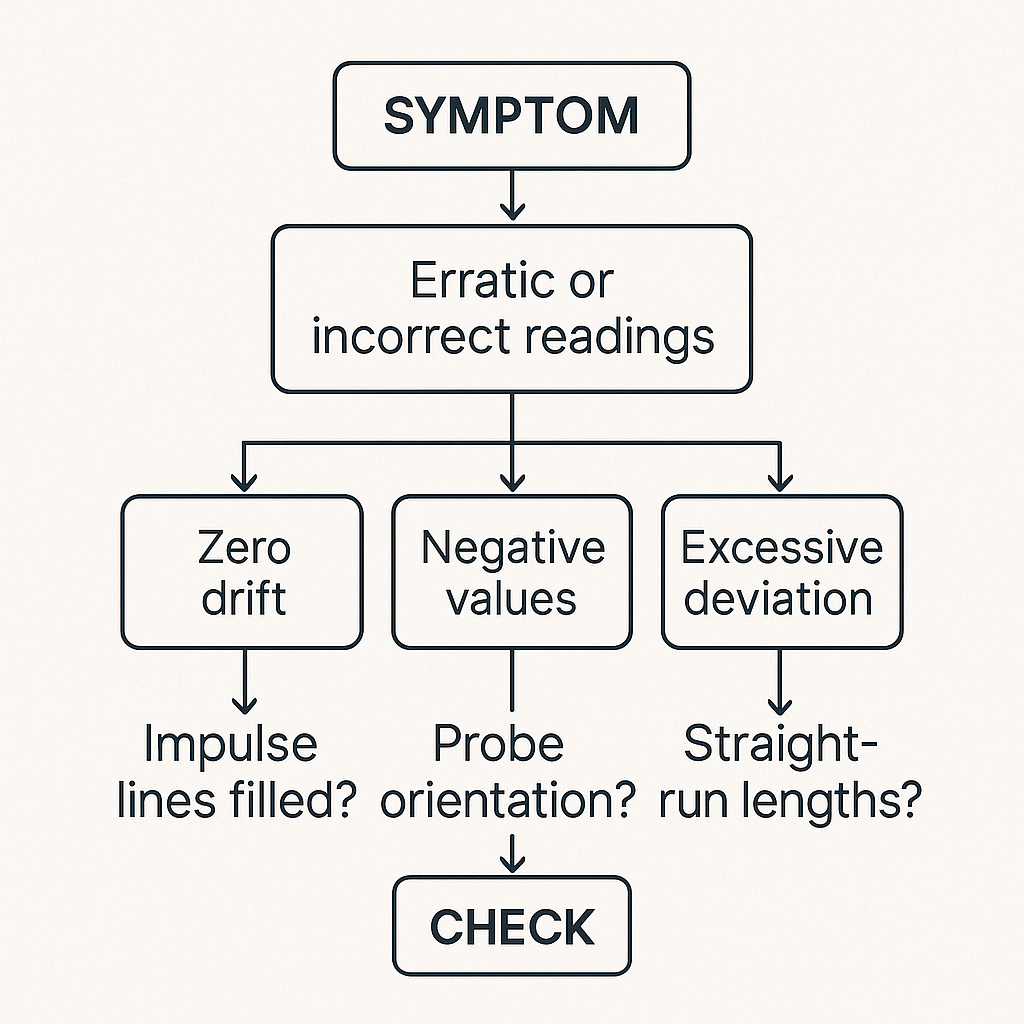

6) Troubleshooting (symptom → likely cause → action)

Zero drifting/negative DP → condensate pooling; trapped air; mis‑orientation → drain, re‑slope, re‑align, quick zero.

Large bias vs. mass balance → wrong quadrant (phase bias); insufficient straight‑run → relocate or add flow conditioner; re‑range.

Noisy signal → wet steam droplets; valve turbulence → move away from disturbances; increase damping; check dryness fraction.

Notes

Where feasible, confirm final siting with CFD for complex layouts.

Achievable uncertainty ≤ ±2.5% with proper installation and configuration.

— End of Part 1 —