Pressure sensors play a critical role in industrial applications. In real operating environments, their performance can be affected by multiple interference factors, and in severe cases, the sensor may even be damaged. Therefore, quality testing is essential. The evaluation can be divided into two major aspects: interference immunity and measurement accuracy.

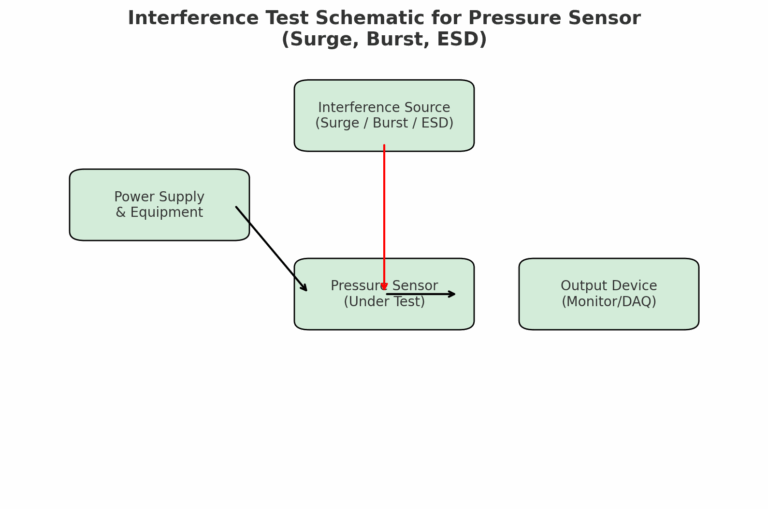

1. Interference Immunity Tests

a) Surge

Definition: A sudden change in voltage or current within microseconds, often caused by lightning strikes, switching of high-power devices, or sudden discharge events.

Impact: May result in permanent sensor damage, no output signal, or display malfunction.

b) Burst (Pulse Group)

Definition: A series of sharp electrical spikes interfering with sensor electronics.

Impact: Causes unstable or fluctuating outputs.

c) Electrostatic Discharge (ESD)

Definition: Discharge of static electricity from the surrounding environment.

Impact: May lead to temporary errors or irreversible sensor damage.

✅ These tests are usually carried out with EMC (Electromagnetic Compatibility) testing equipment to verify whether the sensor can maintain stable performance under harsh interference conditions.

2. Accuracy Verification

Importance

Accuracy is one of the most critical specifications of a pressure sensor. The correctness of the accuracy rating directly determines the reliability of process measurements.

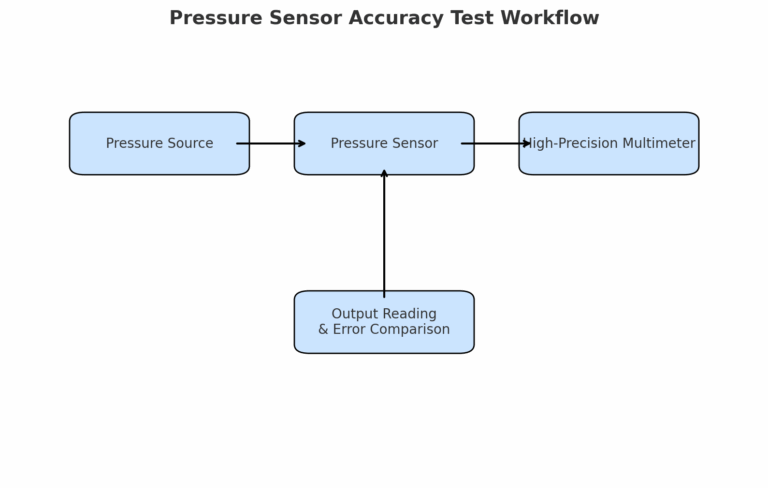

Test Equipment

High-precision digital multimeter (accuracy level: 0.01%, i.e., 1/10,000 FS).

Considered top-grade in laboratory and industrial calibration use.

Test Method

Correctly wire and power the sensor.

Apply pressure incrementally using a standard pressure source.

Collect the output signal (4–20 mA) via the high-precision multimeter.

Compare the measured values with theoretical outputs to determine error.

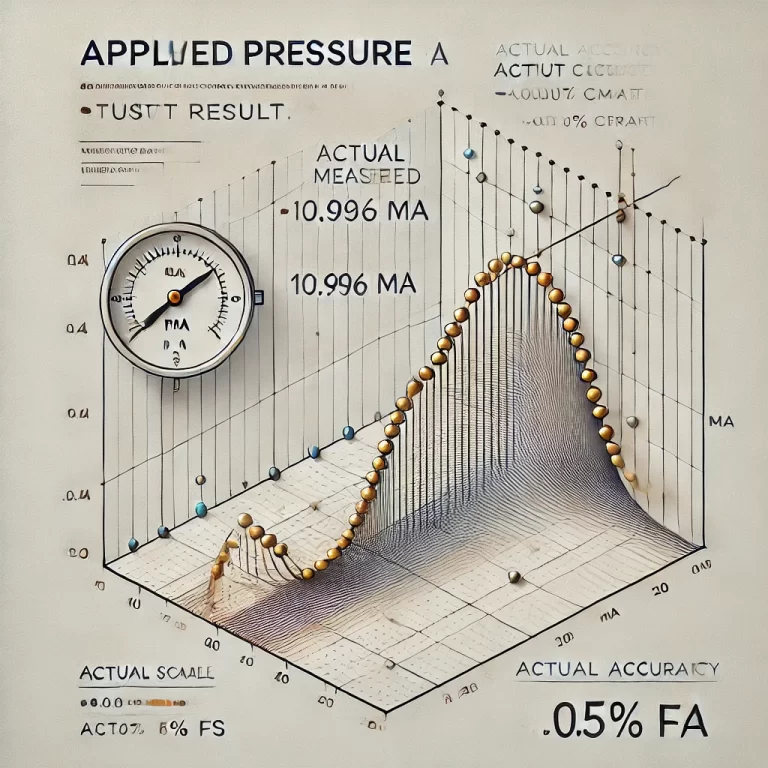

3. Example Case

Sensor Parameters

Range: 0–100 Pa

Output: 4–20 mA

Accuracy: 0.25% FS (±0.04 mA tolerance)

Test Result

When pressurized to full scale (1 MPa), the multimeter displayed 19.996 mA.The deviation was only ±0.004 mA.

Actual achieved accuracy: 0.05% FS, far better than the nominal 0.25% FS rating.

✅ Conclusion

The quality of a pressure sensor should be evaluated from two perspectives:

Interference Immunity: Ensures reliability and long service life under surge, pulse, and ESD conditions.

Accuracy Verification: Confirms that the sensor output is within its specified tolerance and meets industrial measurement requirements.

Only when a sensor passes both sets of tests can it be considered high-quality and suitable for long-term field applications.