Radar level transmitters are widely used in industries such as chemical processing, metallurgy, power generation, and water treatment due to their high accuracy and strong environmental adaptability. However, when installed outdoors, issues like rain, humidity, and condensation can lead to water ingress in the antenna cover, terminal housing, or electronics compartment—causing signal fluctuations, inaccurate measurements, or even device failure.

Based on field experience, this guide presents effective waterproofing and moisture protection measures.

1. Common Causes of Water Ingress

Poor Cable Sealing

Aging or loose sealing rings at the cable entry allow rainwater to seep in along the cable core.Unsealed Terminal Cover

Cover not properly tightened or deformed sealing ring after maintenance.Housing Cracks or Impact Damage

Long-term exposure to UV, cold-induced brittleness, or mechanical impact can cause cracks.Internal Condensation

Large day-night temperature differences can lead to water droplets forming inside the housing.Incorrect Installation Orientation

Upward-facing cable entry increases the likelihood of water pooling.

2. Protection Design & Installation Guidelines

A. During Instrument Selection

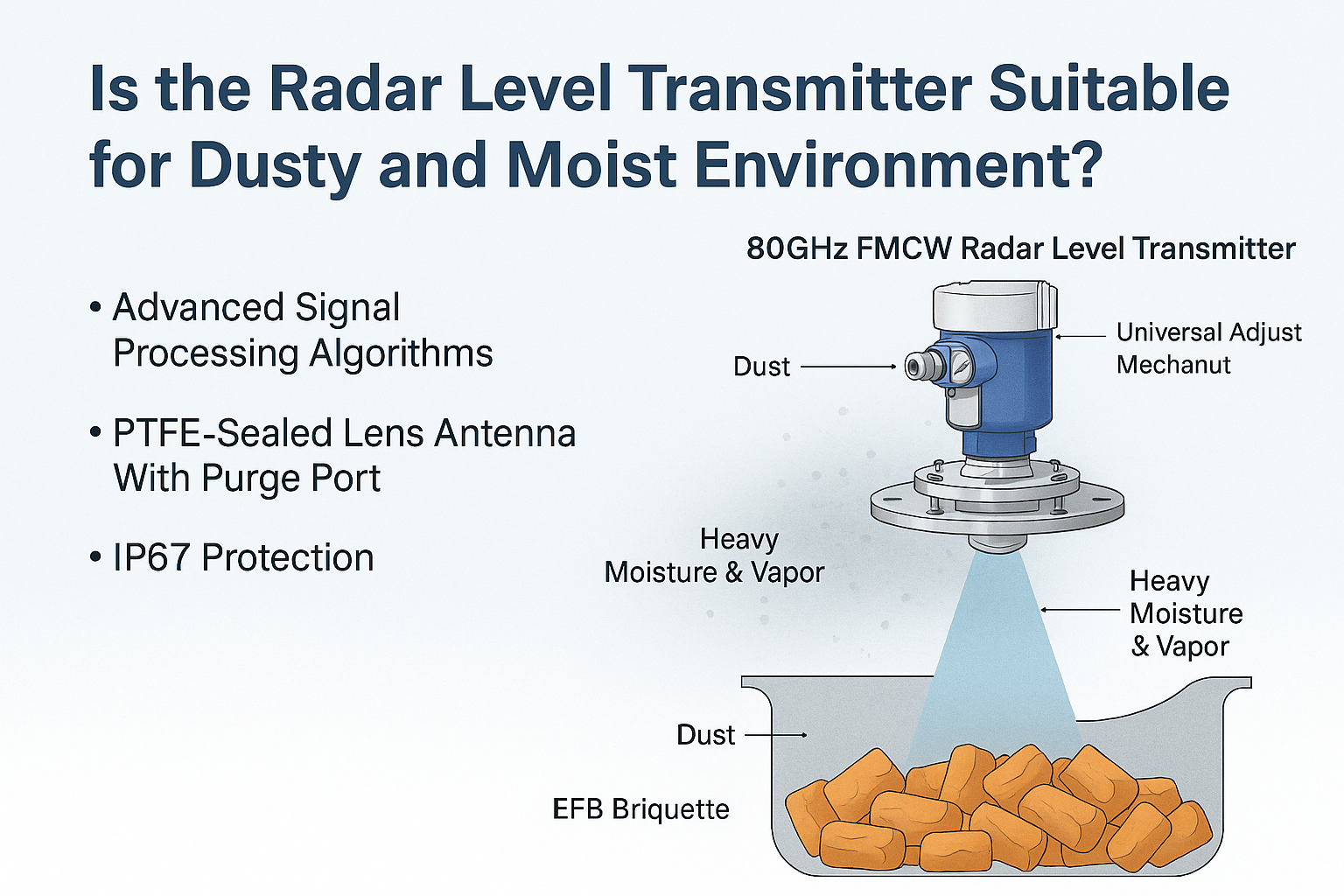

Ingress Protection (IP) Rating:

Choose devices rated IP67 or above.Housing Material:

Prefer painted aluminum alloy or stainless steel for corrosion resistance and weather durability.Cable Glands:

Use industrial-grade waterproof glands with compression nuts (e.g., Re SKE + HAW types).

B. During Installation

Cable Entry Facing Downwards:

Prevents rainwater from flowing along the cable into the housing.Add a Drip Loop:

Create a “U”-shaped drip loop before cable entry to break water path.Example: Radar level transmitter with a downward “U” drip loop cable entry.

Tighten Sealing Rings Evenly:

Check for damage or debris and ensure uniform compression.Apply Waterproof Grease:

A thin layer of silicone grease on threaded joints enhances both sealing and corrosion protection.

3. Daily Operation & Maintenance Tips

Routine Inspections

Check Housing and Seals:

Replace aged or cracked sealing rings promptly.Cable Check:

Ensure drip loop remains intact and gland is tight.Mounting Inspection:

Confirm brackets, flanges, and bolts are secure to avoid tilting and water accumulation.

High Humidity & Rainy Season Measures

Use Desiccant Packs:

Place moisture-absorbing silica gel inside terminal housing. Replace after every maintenance session.Install Breather Valves + Waterproof Membranes:

Balance internal/external pressure to minimize condensation.Avoid Maintenance During Rainstorms:

Prevent long exposure of internals in wet conditions.Example: A domestic radar level transmitter failed after open-cover operation in wet weather.

Emergency Response

If Water Ingress Is Found:

Power off immediately.

Open terminal housing, dry manually.

Use hot air blower or dry compressed air to ensure thorough drying.

Test insulation before powering on.

If PCB Corrosion Occurs:

Replace electronics and record root cause for prevention.

4. Case Study: Power Plant Slurry Tank

Issue:

Radar transmitter readings fluctuated due to rainwater ingress via a vertical cable.

Improvements Implemented:

Re-routed cable downward then upward (drip loop).

Added metal rain cover for the transmitter head.

Installed waterproof breathable membrane + silica gel inside the terminal box.

Established a quarterly seal inspection protocol.

Outcome:

No water ingress failures for over two years post-improvement.

5. Conclusion

Proper sealing, correct installation orientation, and timely maintenance are key to preventing water ingress in outdoor radar level transmitters. Most failures are not due to inadequate IP rating, but rather due to neglect in installation or upkeep.

By following the best practices outlined in this guide, users can significantly reduce failure rates and extend the service life of their instruments.