1) Concept & Scope

Interface level means the height of the boundary between two immiscible liquids of different densities (e.g., oil–water). A dual-flange remote-seal differential pressure transmitter infers the interface height from the pressure difference created by the two liquids across the measurement span. Typical uses: separators, coalescers, desalters, and oil–water interface tanks.

2) Media Requirements

Sufficient density contrast: Avoid pairs with very similar densities; measurement resolution and stability will suffer.

Stable densities: Large density drift with temperature/composition change degrades accuracy; consider temp compensation or narrower operating envelopes.

3) Installation Positioning

Liquid head above the upper flange: Keep the process liquid level always higher than the upper tapping to prevent level and interface moving together, which breaks the DP relationship. Do not allow a third phase (e.g., gas blanket or emulsion band) between the two flanges.

Transmitter elevation: Install the transmitter as close as practical to the tappings and preferably below the lower (high-pressure) flange for easier maintenance and reduced thermal effects on capillaries. Per SH/T 3104-2013 §8.4.8, when mounting above the lower tapping, verify by calculation that the capillary fill fluid will not vaporize.

Environment: Choose locations with minimal vibration, moderate temperature swing, and low corrosion risk—or add protective measures (coatings, enclosures).

4) Capillary & Remote Seal Handling

Length management: Excessive capillary length adds thermal-induced zero shifts. For long runs or difficult routing, consider an electronic remote interface level meter instead of very long capillaries.

Minimum bend radius: ≥ 50 mm. Follow mechanical protection and routing good practice. (GB 50093-2013 §6.1.12.)

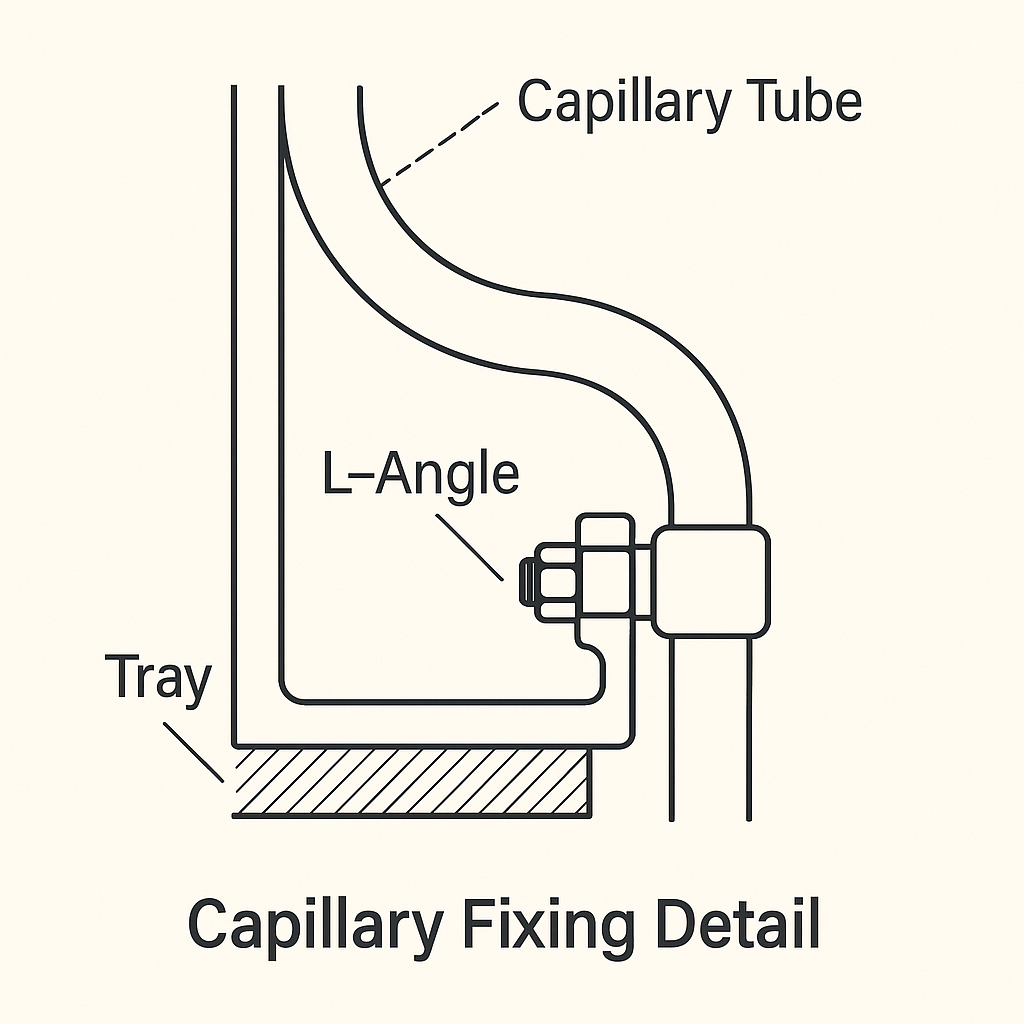

Rigid fixing: Support any free-span capillary on L-angle (e.g., 40/50) or tray to prevent wind-induced oscillation and stress on seals.

Thermal control: If local extremes approach the fill-fluid pour/boiling points or ambient varies rapidly, add insulation or heat tracing to keep fill-fluid single-phase and stable. SH/T 3104-2013 §8.4.6 also recommends fixing capillaries with angle steel and applying heat-trace/insulation where needed.

5) Mechanical & Protection Details

Gasketing: Select gasket type/size carefully; avoid any extrusion into the seal diaphragm area that can bias pressure transmission.

Bolting: Tighten in a cross pattern to ensure flatness and even gasket load; re-torque after thermal soak where applicable.

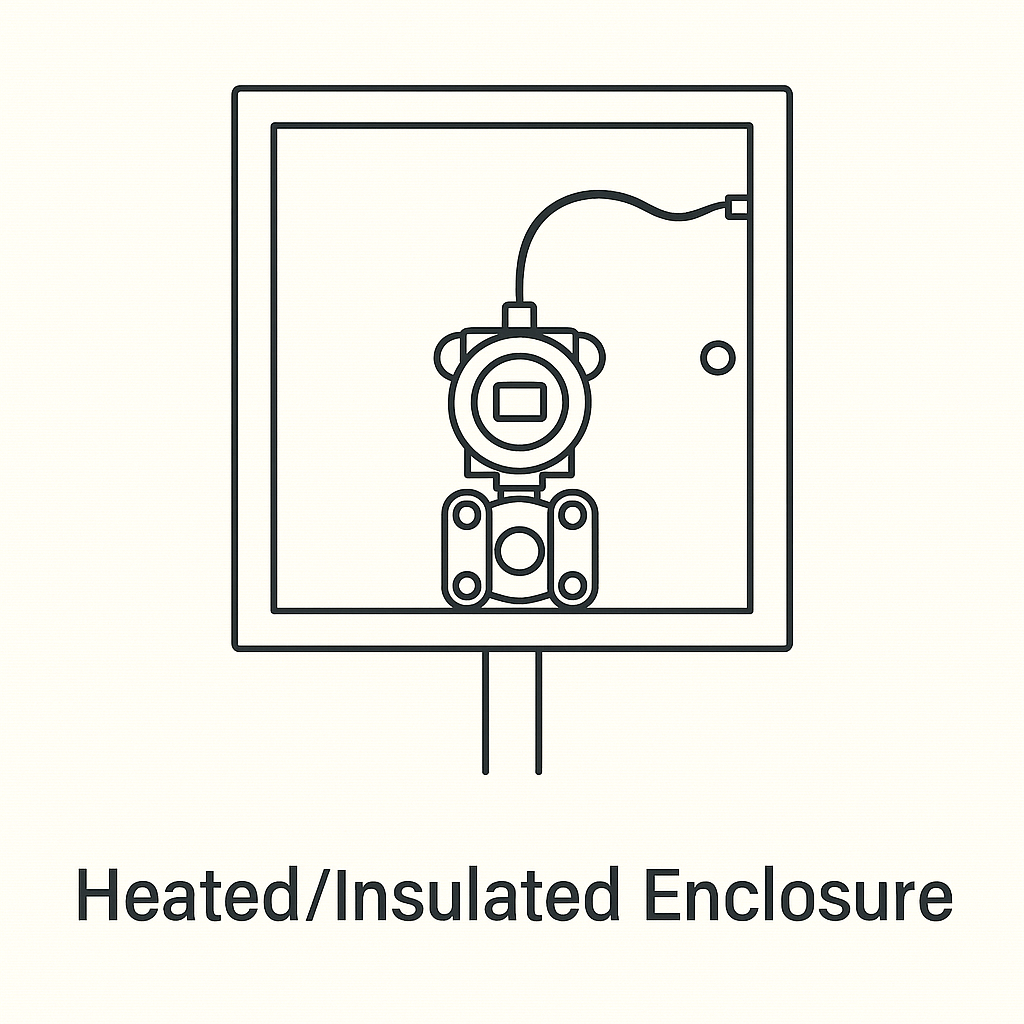

Weather protection: For outdoor installs, use a heated/insulated instrument enclosure so the electronics and LCD operate within rated temperature and ingress protection.

6) Configuration & Commissioning Checklist

Collect process data

ρ_heavy (e.g., water/brine), ρ_light (e.g., oil) at operating temperature(s)

Expected interface range and overall liquid head above upper flange

Range & LRV/URV

Calculate DP at 0% (all light) and 100% (all heavy) interface conditions including remote-seal head corrections and capillary orientation.

Compensations

Consider temperature effects on ρ and on capillary fill fluid; enable temp compensation if available.

Zero check

With stable fluid conditions, verify zero/span; note any offset from ambient gradients and adjust trim within limits.

Response & damping

Set damping to suppress slugs/emulsion waves without masking real movement.

Functional test

Simulate interface movement (controlled draining/filling or portable column) to confirm linearity and end-points.

7) Common Failure Modes & Fixes

Capillary thermal imbalance → drifting zero

Fix: Insulate/heat-trace both capillaries symmetrically; avoid routing one near hot equipment, the other in shade.

Third phase in the leg (gas pocket/emulsion)

Fix: Reposition tappings; ensure continuous liquid column; consider baffles or stilling wells.

Seal diaphragm distortion from gasket/bent bolts

Fix: Correct gasket selection and cross-torque; replace damaged seals.

Vibration-induced noise

Fix: Add supports; relocate transmitter; increase damping within response requirements.

8) Interface DP—Engineer’s Quick Reminder

For a vertical two-liquid column spanning the two flanges:

Let h = height of heavy phase in span; H = center-to-center distance between flanges.

DP ≈ g [ρ_heavy · h + ρ_light · (H − h)] + (remote-seal/capillary head corrections).

Solve for h across 0–H to map to 0–100%.

Always incorporate: transmitter elevation differences, seal fill fluid heads, and actual tap elevations per P&ID/GA.

9) When to Prefer Alternatives

Very small Δρ (near-miscible fluids), long/uneven capillaries, or extreme/rapid ambient swings → consider displacer with density compensation, guided-wave radar (GWR) for interfaces, or electronic remote DP solutions.

10) Data You Should Request/Record (Spec Template Snippet)

Service: tank ID, fluid pair, operating T/P ranges

ρ_light @ °C, ρ_heavy @ °C; expected emulsion thickness

Tap elevations (upper/lower), H distance, nozzle IDs

Seal type/size/materials; fill fluid type; capillary length & routing plan

Enclosure: IP/NEMA rating; heater/insulation plan; ambient design min/max

Damping & output (4–20 mA/HART/FF), hazardous area approvals

11) Field Notes — Do/Don’t Summary

Do

Keep upper tap submerged at all times

Fix capillaries on angle steel; bend radius ≥ 50 mm

Match thermal environments for both capillaries

Use cross-pattern bolting and correct gaskets

Provide weather/thermal protection for outdoor units

Don’tRoute one capillary across a hot pipe and the other in shade

Allow gas pockets or a third phase between taps

Overtighten bolts near seal diaphragms

Exceed capillary length without evaluating electronic alternatives

(All aligned with the cited installation norms and construction/QA guidance.)