1. Introduction

In industries such as energy, chemical processing, and food production, accurate fluid measurement is critical for process control, fiscal metering, and safety compliance. The Roots flow meter, also known as the lobed gear meter, is highly regarded for its precision in measuring high-viscosity fluids. However, its mechanical accuracy must be maintained through regular calibration and verification to ensure reliability over time.

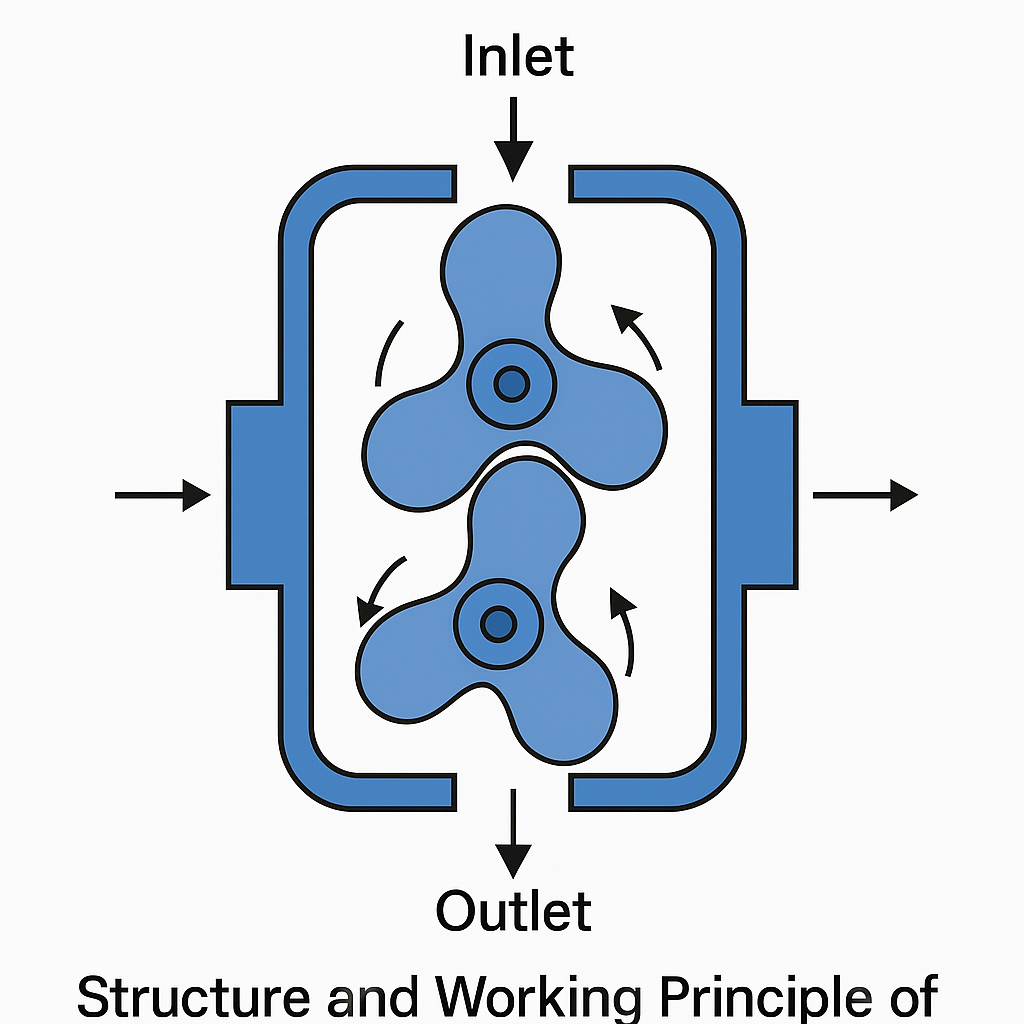

2. Operating Principle

Roots flow meters operate based on the principle of positive displacement. Two precisely machined, counter-rotating lobed rotors are housed within a chamber. As the fluid flows, pressure differences drive the rotors, displacing a known volume with each revolution. The cumulative number of rotations corresponds directly to the total volume passed through the meter.

However, over time, various factors such as wear, corrosion, fluid contamination, bearing degradation, and changes in fluid temperature and viscosity may affect the internal clearances and displacement efficiency, introducing measurement errors. Calibration addresses these issues by aligning indicated flow values with actual flow.

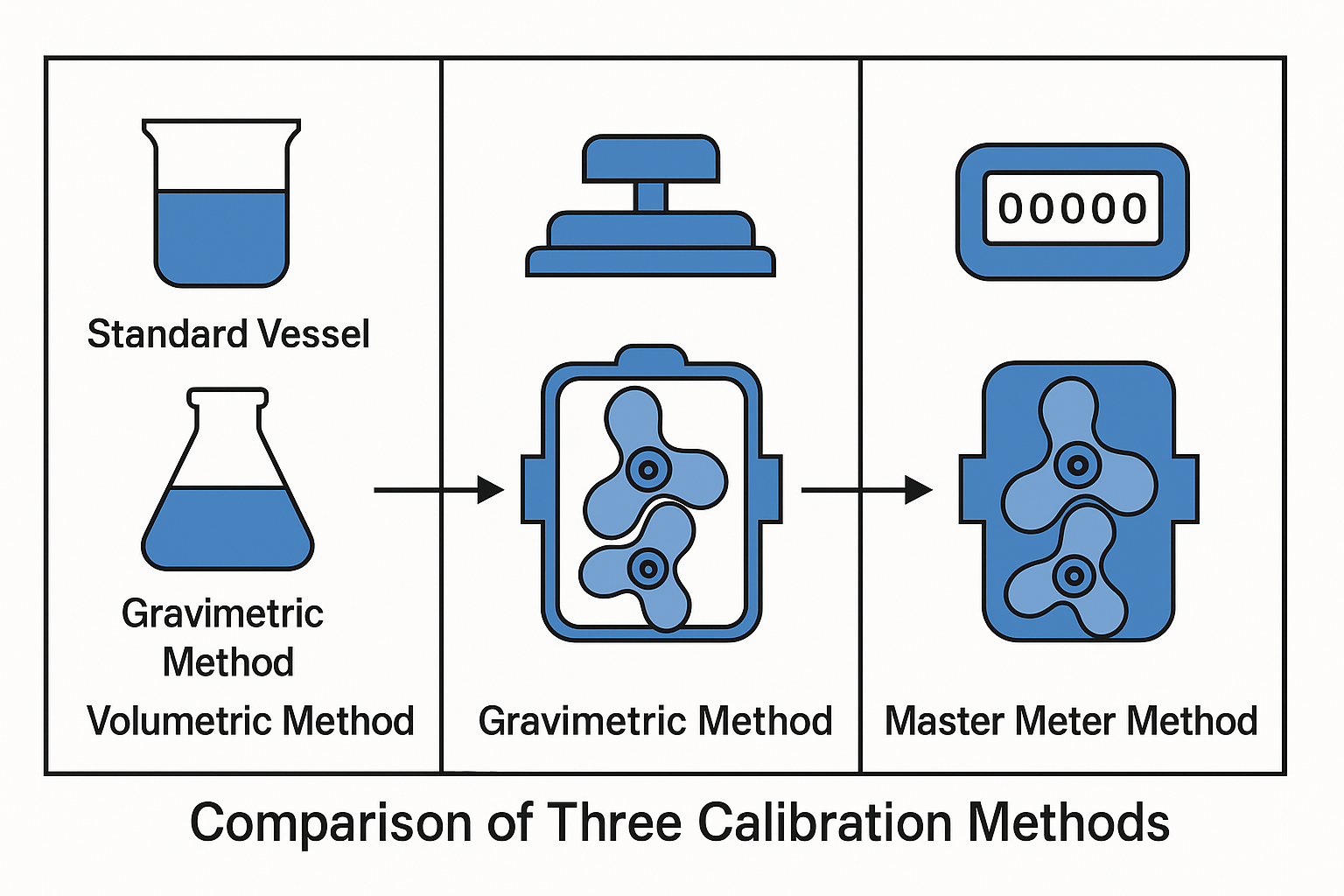

3. Common Calibration Methods

Roots flow meters are typically calibrated using real-flow calibration methods under conditions that closely simulate actual operating environments. The three main calibration methods include:

3.1 Volumetric Method

This classical method involves comparing the flow meter’s indicated volume against a certified volumetric standard (e.g., a proving tank or calibrated cylinder). It is known for high accuracy and forms the basis of many national metrology standards.

3.2 Gravimetric Method

Used primarily for liquid media, this method involves collecting the liquid in a container placed on a precision scale. The collected mass is then converted to volume using known fluid density. This method avoids uncertainty from direct density measurements.

3.3 Master Meter Method

A high-accuracy reference meter (master meter), previously calibrated to a higher standard, is installed in series with the meter under test. Their readings are compared under stable flow conditions. This method is efficient and suitable for in-line calibration.

4. Calibration Procedure

A standardized calibration process typically includes the following steps:

Visual Inspection: Check for physical damage, seal integrity, and contamination.

Test Setup: Connect the meter to a flow calibration rig with controlled flow rates and known fluid properties.

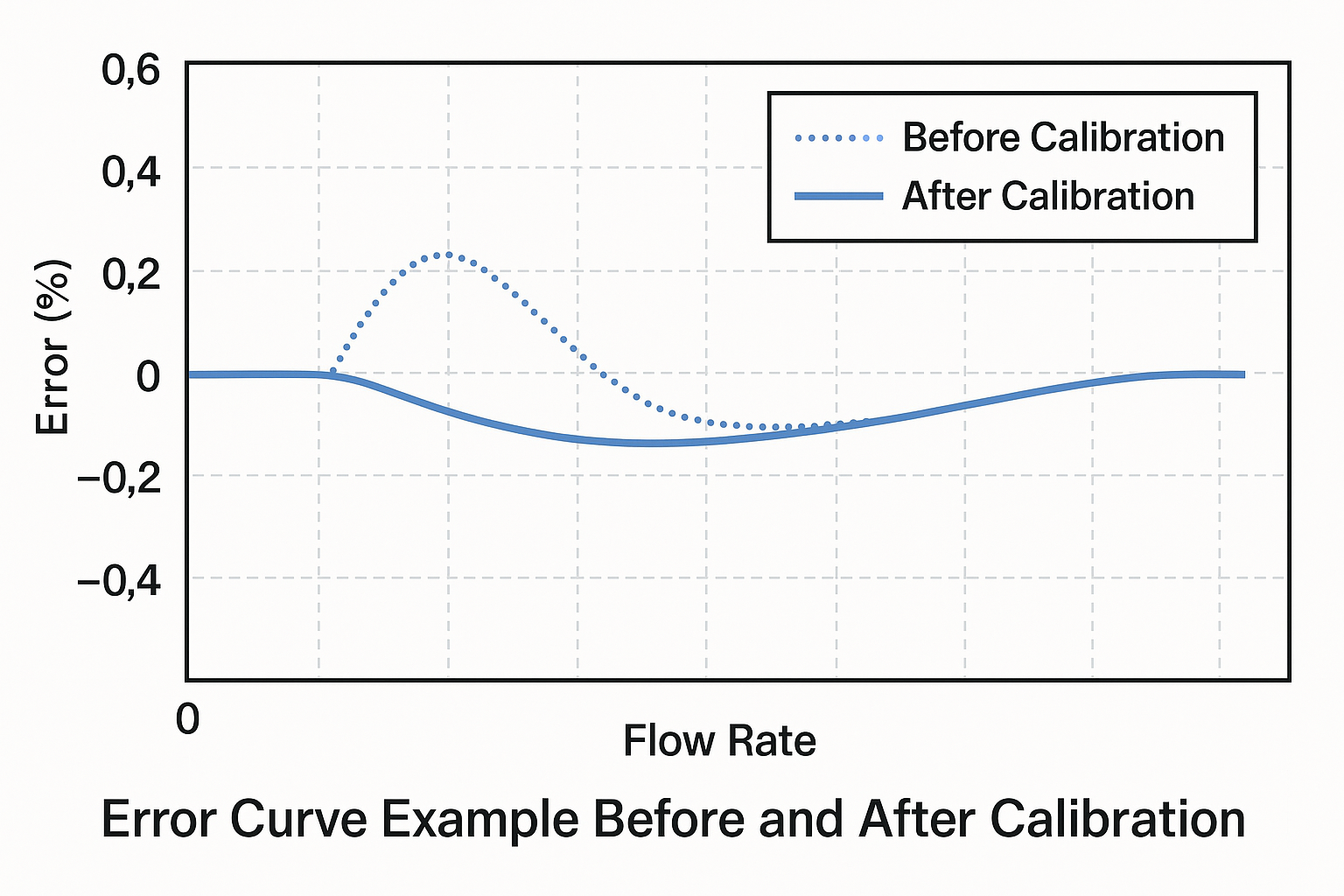

Multi-Point Testing: Conduct measurements at various flow rates, such as minimum (Qmin), nominal (Qnom), and maximum (Qmax) values, possibly with different viscosity fluids.

Data Evaluation: Calculate deviation, linearity, and repeatability. Plot error curves if necessary.

Adjustment (if applicable): Adjust internal coefficients or correction factors to align meter output with true values.

Table 1: Sample Calibration Test Points and Tolerances

| Flow Point | Flow Range (%) | Calibration Fluid | Method | Allowed Error |

|---|---|---|---|---|

| Qmin | 5% | Diesel | Volumetric | ±0.5% |

| Qnom | 50% | Diesel | Master Meter | ±0.3% |

| Qmax | 100% | Diesel | Master Meter | ±0.3% |

5. Importance of Calibration

A valid calibration is more than a certificate; it provides a comprehensive assessment of the flow meter’s health. Regular calibration helps:

Ensure Measurement Accuracy: Corrects drift due to wear or environmental changes.

Prevent Economic Losses: Avoids errors in custody transfer, billing, and product loss.

Enable Predictive Maintenance: Identifies wear trends early to schedule timely servicing.

6. Conclusion

Calibration and verification are essential practices to uphold the measurement integrity of Roots flow meters. Beyond regulatory compliance, it enhances operational reliability, trade fairness, and process efficiency. Establishing a routine calibration schedule is a best practice in metrological management.