1. Introduction

In process industries such as chemical, petrochemical, and power generation, flow measurement is a critical parameter for process optimization, cost control, and safety assurance.

Among various flow meters, differential pressure (DP) flow transmitters hold more than 60% of the market share due to their simple structure, strong adaptability, and wide applicability.

However, the accuracy of DP transmitters relies heavily on the integrity of the impulse line system. Blockages, condensate accumulation, gas bubbles, or phase changes in the process medium can introduce significant measurement errors.

Regular purging (draining or venting the impulse line) is therefore an essential maintenance practice to ensure reliability and long-term stability.

2. Why Regular Purging is Necessary

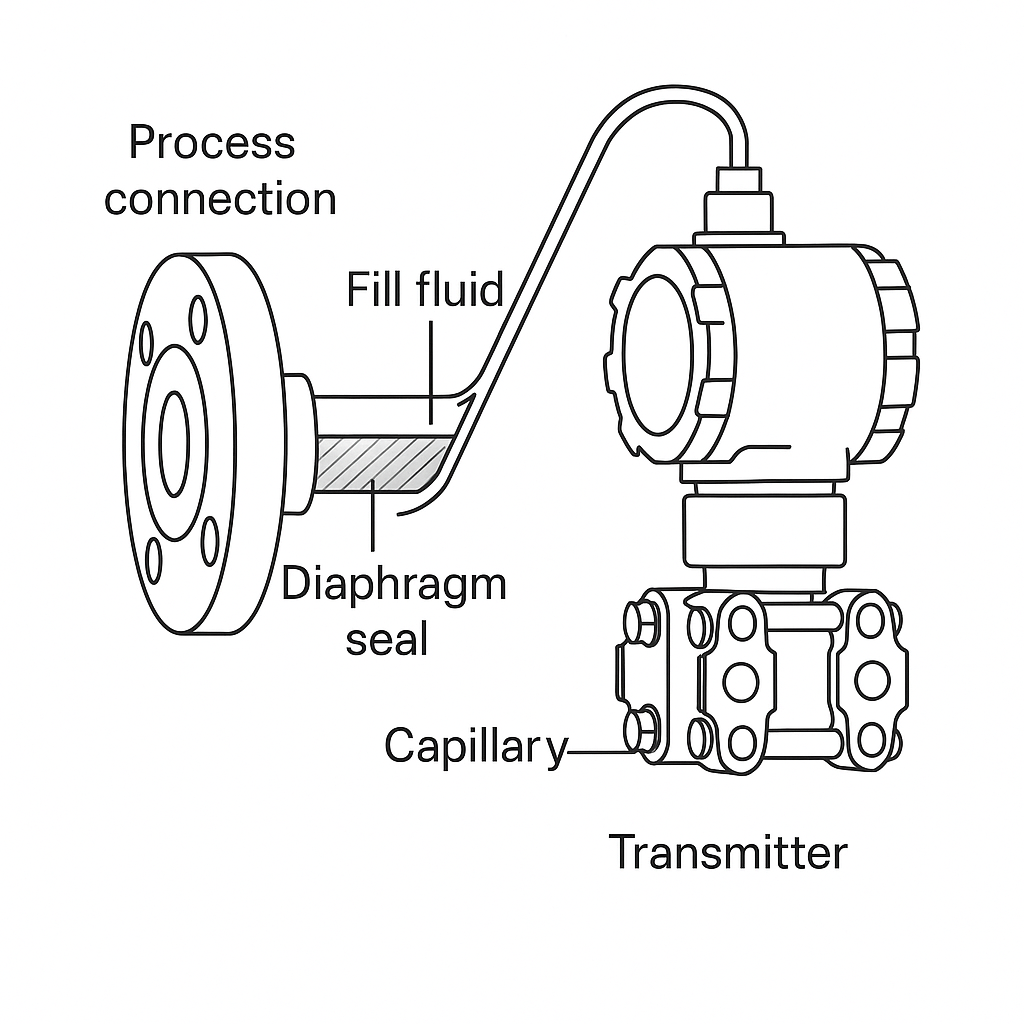

DP transmitters calculate flow based on the pressure difference across a primary element (e.g., orifice plate, nozzle, Venturi). The stability of this measurement depends on the cleanliness and proper filling of impulse lines.

Key reasons for purging include:

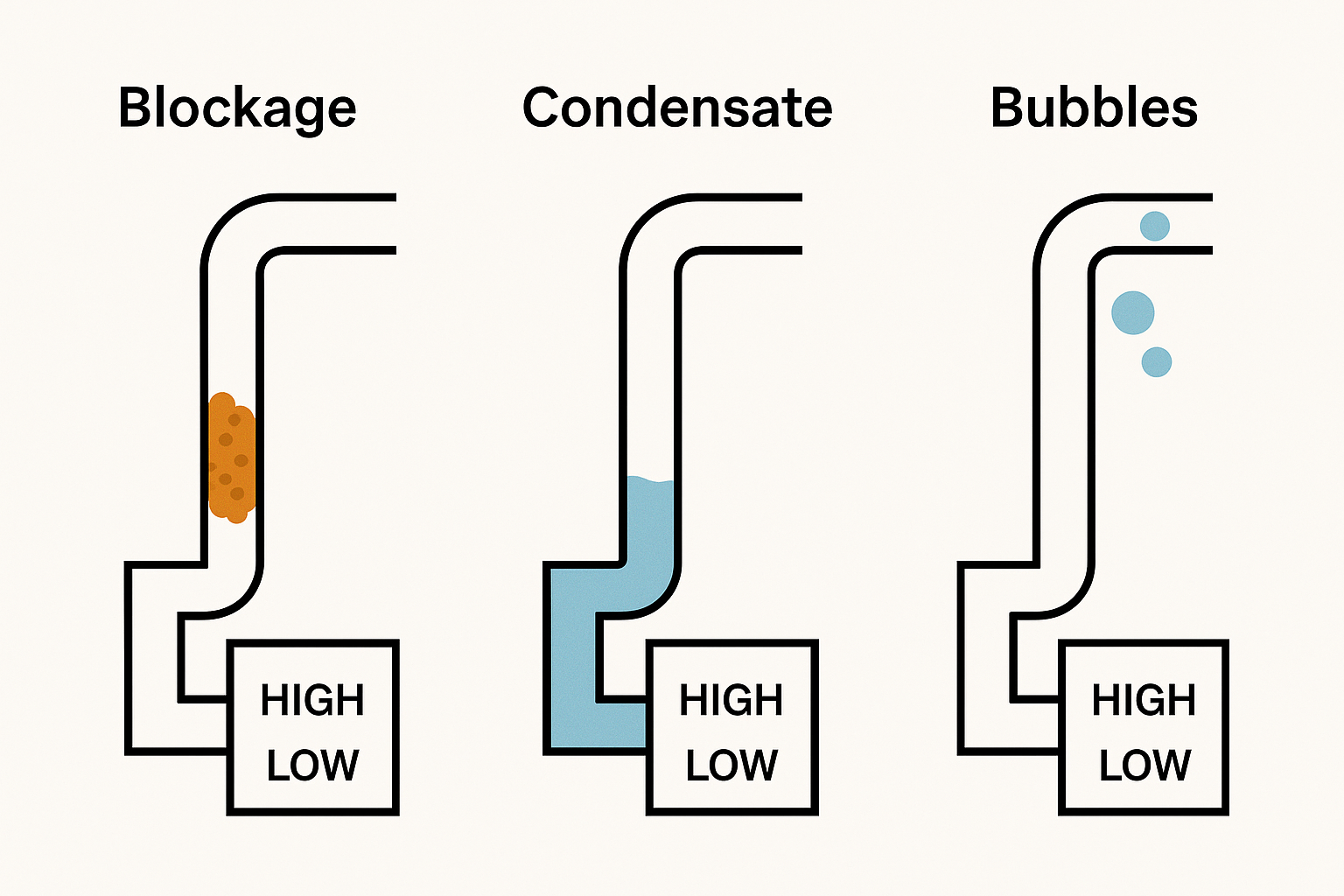

Blockage or Sediment Accumulation

Solid particles, oil, or impurities may deposit inside impulse lines.

This leads to distorted differential pressure transmission and large measurement deviations.

Condensate Accumulation

In gas or steam measurement, condensate may accumulate and form liquid columns, adding extra hydrostatic pressure.

Results in systematic errors and false readings.

Gas Bubble Formation

In liquid service, gas bubbles inside impulse lines can cause unstable signals and oscillations.

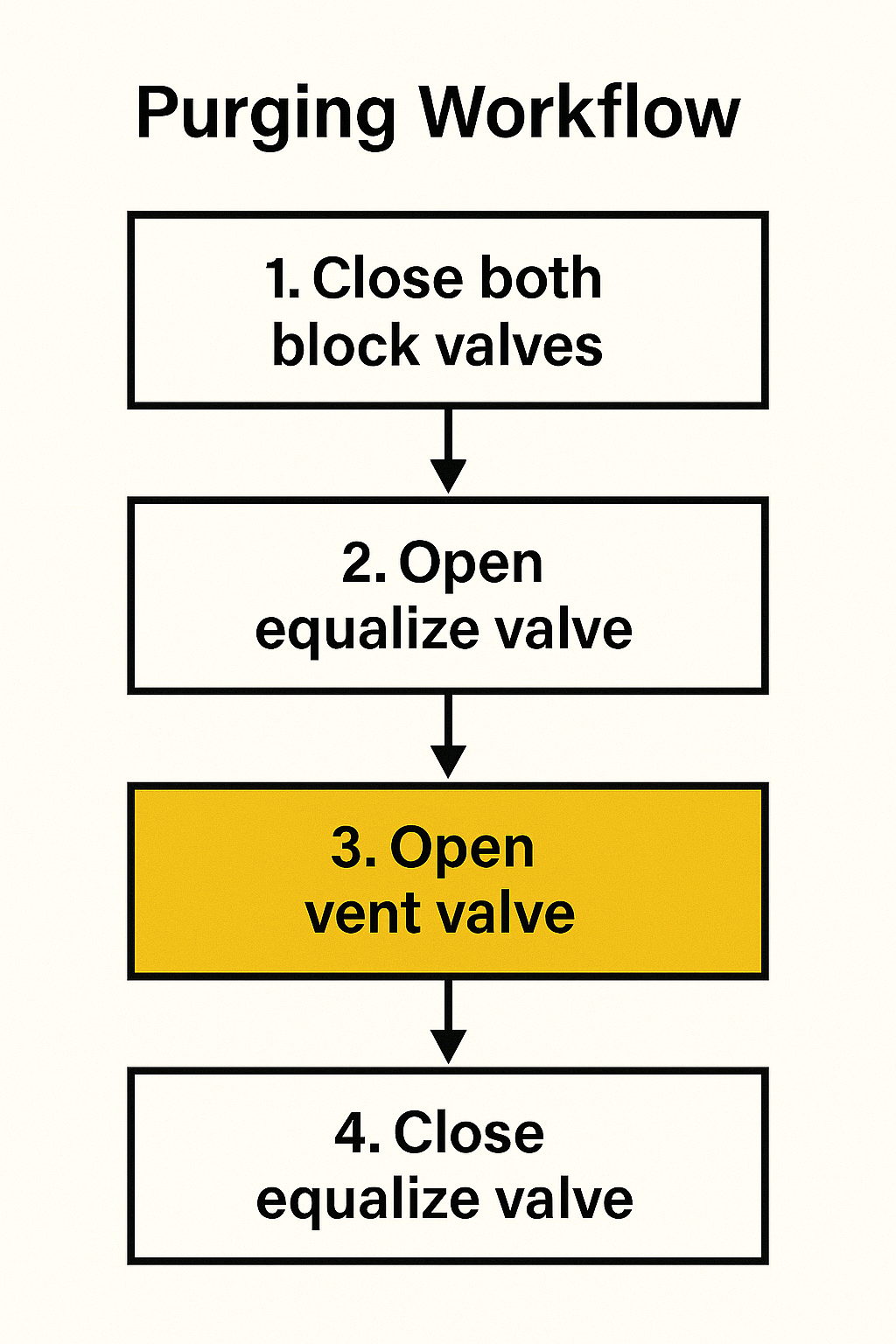

Zero Drift Correction

Over time, transmitters may experience zero-point drift due to temperature stress or mechanical strain.

During purging, operators can close the equalizing valve, check zero, and recalibrate.

Medium-Specific Issues

High-temperature media (steam): condensate evaporation → risk of gas pocket formation.

Low-temperature media (cryogenic liquids): freezing/solidification → line blockage.

Viscous media (heavy oil): deposits on line walls → requires frequent flushing.

3. Valve Manifold Selection: 3-Valve vs. 5-Valve

DP flow transmitters are typically connected via valve manifolds to control impulse line operations. Choosing the right manifold configuration depends on the complexity of the process and maintenance requirements.

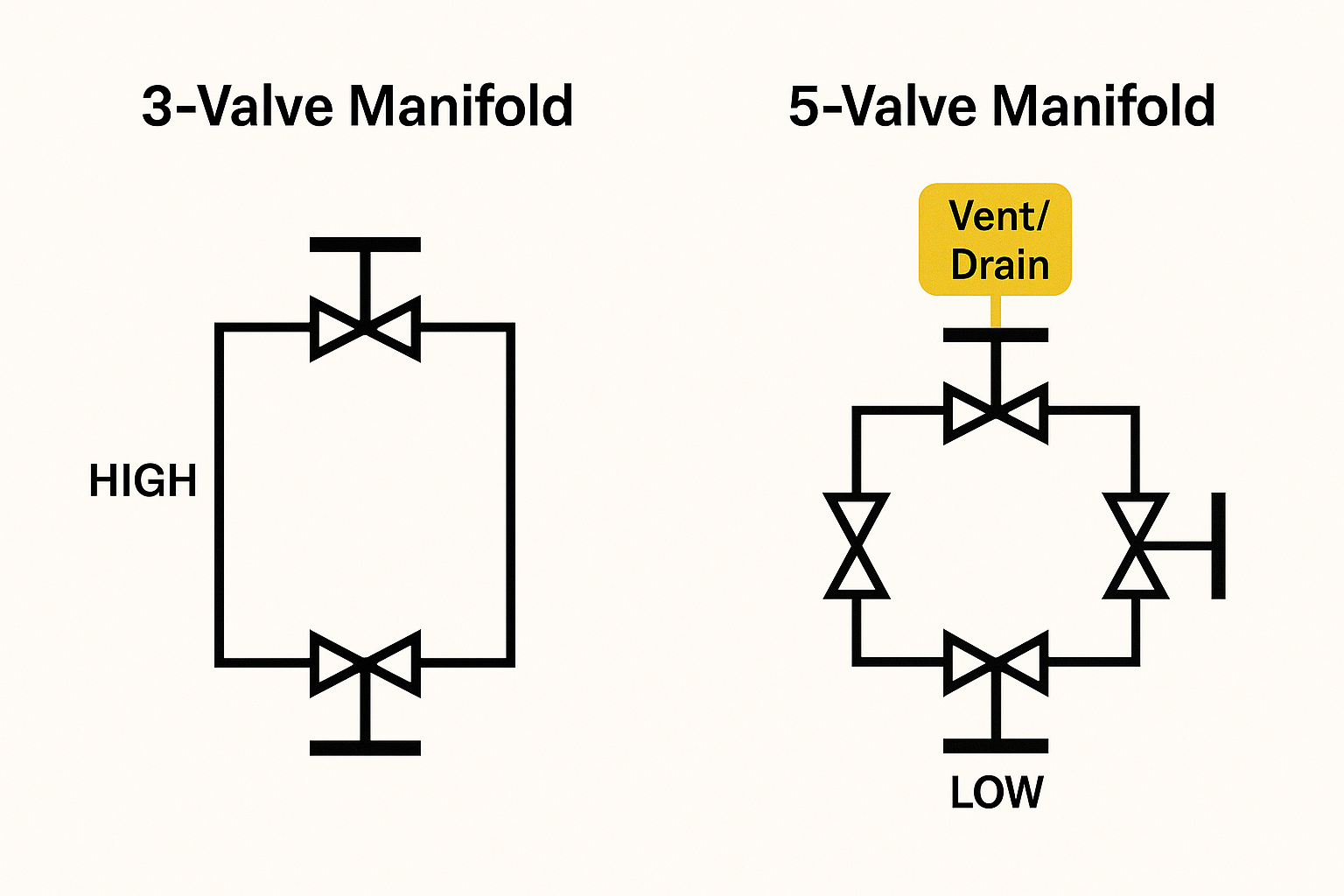

3-Valve Manifold

Structure: High-pressure valve, low-pressure valve, equalizing valve.

Functions: Isolates transmitter from impulse lines, balances pressure chambers during commissioning.

Best suited for:

Conventional flow or level measurements (e.g., orifice flow, tank level).

Simple and clean processes.

Cost-sensitive projects.

Limitations:

No dedicated vent/drain function; relies on transmitter body drain screws.

Less efficient for purging and maintenance.

5-Valve Manifold

Structure: Three-valve functions plus two vent/drain valves (one on each side).

Functions:

Direct venting/draining of impulse lines.

Online transmitter zero check without shutdown.

Best suited for:

Custody transfer and fiscal measurement requiring frequent calibration.

Media prone to gas bubbles, condensate, or solid impurities.

High-accuracy or safety-critical applications in oil & gas, chemical, or power industries.

Advantages:

Faster maintenance and reduced downtime.

Safer and more effective cleaning of impulse lines.

📊 Comparison Table — 3-Valve vs 5-Valve Manifold

| Feature | 3-Valve Manifold | 5-Valve Manifold |

|---|---|---|

| Structure | 2 isolation + 1 equalizing | 2 isolation + 1 equalizing + 2 drain/vent |

| Maintenance | Requires transmitter drain screw | Dedicated vent/drain valves |

| Purging Efficiency | Low | High |

| Calibration Support | Requires shutdown | Online zero check |

| Cost | Lower | Higher |

| Suitable for | Simple, clean process | Complex, high-accuracy, safety-critical |

4. Process Conditions Requiring Frequent Purging

Purging frequency depends on medium properties, process dynamics, and operational conditions. Regular purging is strongly recommended under the following:

Media Characteristics

Impurities: wastewater, slurry, oil with suspended solids.

Crystallizing or fouling media: high-temperature steam, heavy oil.

Gas/steam prone to condensate formation.

Operating Conditions

High-temperature service: risk of condensate evaporation → gas pocket formation.

Low-temperature service: medium solidification risk → blockage.

Frequent pressure swings: induces phase changes (gas liquefaction or liquid vaporization).

Process Dynamics

Large flow fluctuations in batch or intermittent processes.

Frequent start/stop operations.

Long-term continuous operation → natural sediment buildup.

5. Conclusion

Purpose of purging:

Remove deposits, gas bubbles, and condensate.

Correct zero drift and ensure accurate DP transmission.

Valve manifold selection:

3-valve manifolds → low-cost, simple, suitable for stable and clean conditions.

5-valve manifolds → better suited for complex, high-accuracy, or high-safety requirements.

Critical processes requiring purging:

Impurity-rich, high/low temperature, gas/steam measurement, or long-term continuous service.

Regular purging, combined with appropriate manifold selection, significantly enhances the accuracy, reliability, and service life of differential pressure flow transmitters.