1. Introduction

The accuracy grade of a level meter is one of its most critical performance indicators. It is usually expressed as a percentage relative to the full scale (FS). Due to different measurement principles and application environments, the achievable accuracy varies significantly.

This article provides a systematic overview of:

General accuracy classification

Accuracy characteristics of different types of level meters

Application-based recommendations

Influencing factors

Relevant standards and compliance requirements

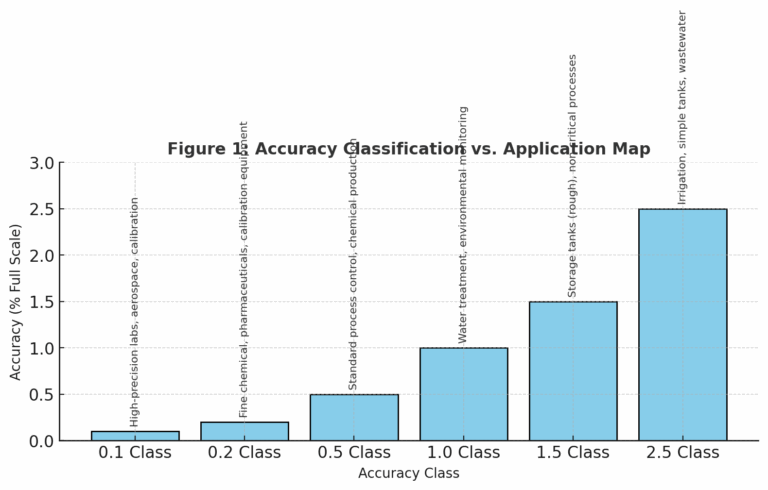

2. Accuracy Classification (General Guidelines)

Based on international and Chinese standards (e.g., GB/T 13283-2008), accuracy grades can generally be divided as follows:

| Accuracy Grade | Typical Deviation | Application Scenarios |

|---|---|---|

| 0.1 Class | ±0.1% FS | High-precision labs, aerospace, calibration facilities |

| 0.2 Class | ±0.2% FS | Fine chemical industry, pharmaceuticals, calibration equipment |

| 0.5 Class | ±0.5% FS | Standard process control, chemical production |

| 1.0 Class | ±1.0% FS | Water treatment, environmental monitoring |

| 1.5 Class | ±1.5% FS | Storage tanks (rough measurement), non-critical processes |

| 2.5 Class | ±2.5% FS | Irrigation, simple tanks, wastewater pools |

3. Accuracy of Different Level Meter Types

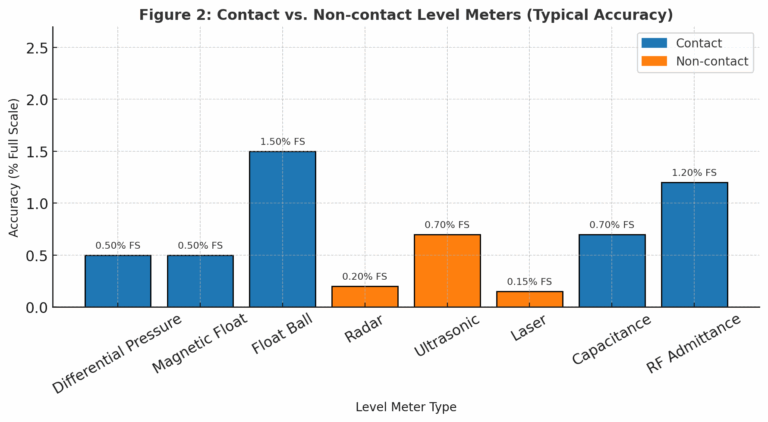

3.1 Contact Type

Differential Pressure Level Transmitter

Accuracy: 0.5–1.0 class; high-end models up to 0.2 class

Influences: fluid density & temperature, leakage in impulse lines, installation verticality, zero drift

Core factor: transmitter precision (e.g., 0.075 class possible)

Magnetic Float / Magnetic Flap Level Gauge

Accuracy: 0.5–1.0 class

Typical indication error: ±10 mm (must be converted into %FS)

Sensitive to float density matching, wall friction, medium adhesion

Float Ball Level Gauge

Accuracy: 1.0–2.5 class

Limitations: mechanical wear, surface fluctuations, long-term drift

3.2 Non-contact Type

Radar Level Meter

Accuracy: 0.1–0.5 class; high-frequency 76–81 GHz models up to ±1 mm

Influences: dielectric constant, tank internals, installation angle, blind zone compensation

Ultrasonic Level Meter

Accuracy: 0.5–1.0 class (typically ≤±0.5% FS or ±5 mm)

Influences: temperature/humidity, vapor, foam → require temperature compensation and echo analysis

Laser Level Meter

Accuracy: 0.1–0.2 class (up to ±1 mm)

Resistant to dust/fog; high cost and strict installation conditions

3.3 Other Types

Capacitance Level Meter

Accuracy: 0.5–1.0 class

Sensitive to dielectric constant variation, conductivity, temperature

RF Admittance Level Meter

Accuracy: 1.0–1.5 class

Strong anti-adhesion; good for solids; generally less precise than radar/laser

4. Application-Oriented Accuracy Recommendations

| Application Scenario | Recommended Instrument | Accuracy Range | Notes |

|---|---|---|---|

| High precision (e.g., LNG storage, pharma reactors, custody transfer) | Radar level (0.1 class), Laser level (0.1 class) | ±0.1% FS | Require proper installation, obstacle avoidance, annual calibration |

| Standard industrial processes (e.g., chemical tanks, water treatment) | Differential pressure (0.5 class), Magnetic float (0.5 class) | ±0.5% FS | Balance cost, reliability, ease of maintenance |

| Low-cost / coarse measurement (e.g., wastewater, agriculture) | Ultrasonic (1.0 class), Float ball (2.5 class) | ±1.0–2.5% FS | Sensitive to environmental interference and liquid turbulence |

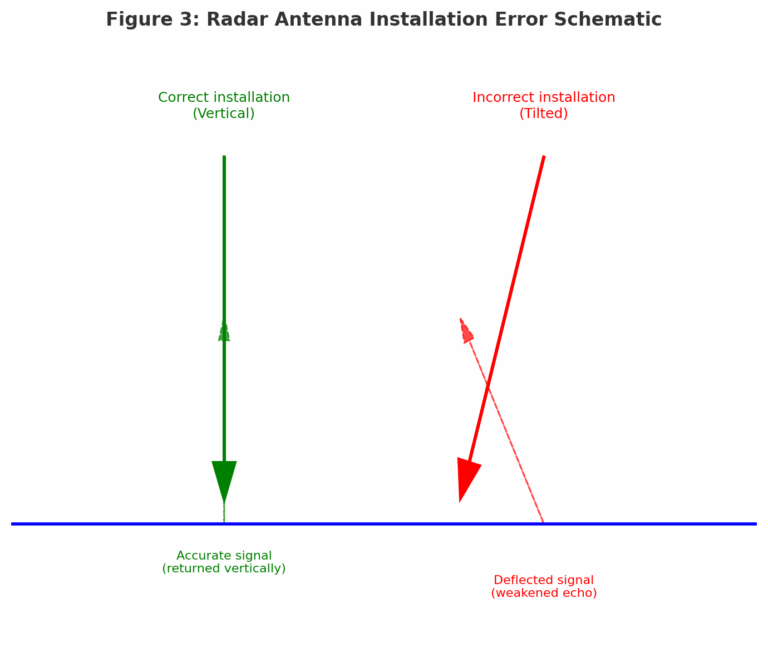

5. Key Factors Affecting Accuracy

Installation Errors

Radar antenna misalignment, improper blind zone handling, incorrect reference plane definition

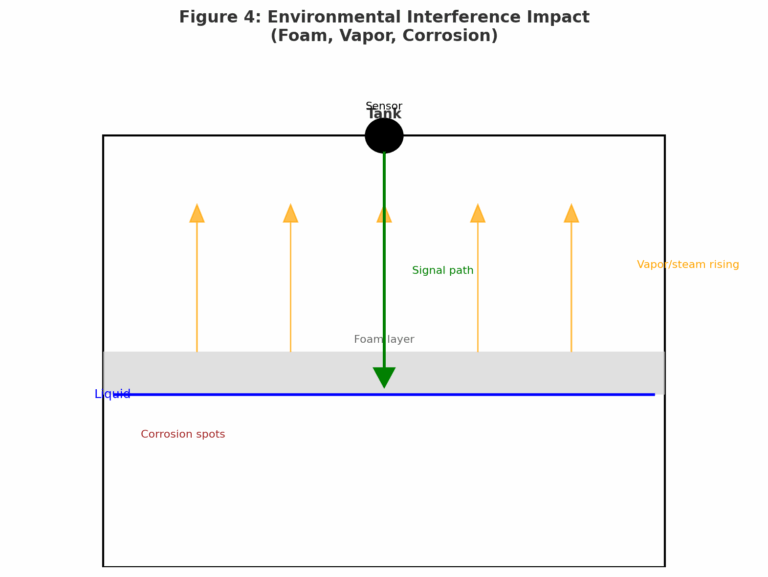

Environmental Stress

High temperature, pressure, corrosion, vibration

Example: magnetic float corrosion changes buoyancy density

Medium Characteristics

High viscosity, foam, crystallization/adhesion cause drift or echo distortion

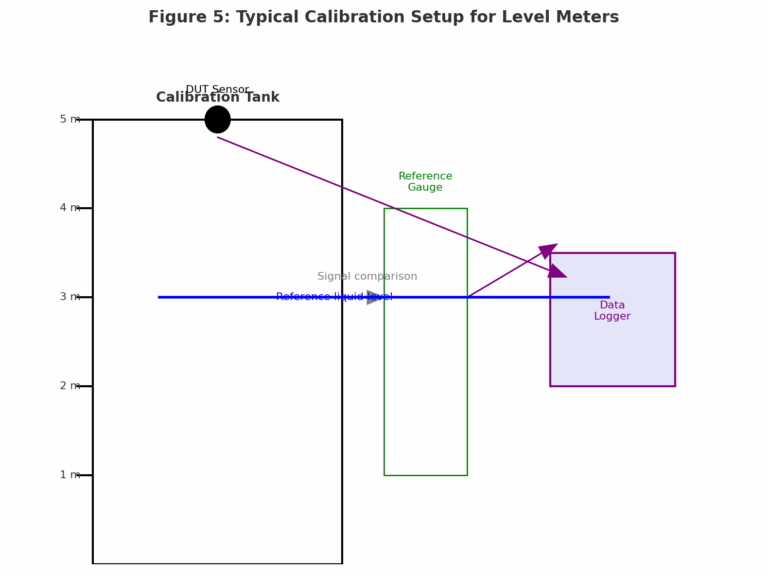

Calibration & Maintenance

Extended usage (>1 year without verification) may degrade accuracy by 1–2 grades

Recommendation: establish regular calibration and in-field verification schedules

6. Standards and Compliance

GB/T 36592-2018 – Radar Level Meter Technical Requirements (accuracy ≥ 0.5 class; high-end up to 0.1 class)

JB/T 10729-2007 – Magnetic Float Level Gauge (indication error ≤ ±10 mm)

JJG 558-2013 – Verification Regulation for Hydrostatic Level Instruments (≤ ±0.5% FS)

GB/T 17886-2009 – General Specifications for Industrial Automation Instruments (accuracy, repeatability, linearity)

GB/T 11886-2001 – Differential Pressure Level Meters (≤ ±1.0% FS; span ratio 1:10–1:100)

Note: Industries such as petrochemical, power, and food may impose stricter internal requirements.

7. Conclusion

The accuracy of a level meter is determined not only by its measurement principle but also by installation quality, medium properties, environmental stress, and maintenance strategy.

Radar and laser meters provide the highest accuracy for custody transfer and critical processes.

Differential pressure and magnetic float types remain reliable choices for conventional industrial use.

Ultrasonic and float ball types are suitable for low-cost, non-critical applications.

Recommendation: Always select level instruments based on process tolerance, compliance requirements, and total lifecycle cost, supported by a robust calibration plan.