When vessels run hot and sealed—think reactors, molten salt tanks, or high-temperature oil reservoirs—level measurement must withstand heat, pressure, vapor, and zero-leak requirements. This guide distills practical choices and installation notes to help you select reliably and safely.

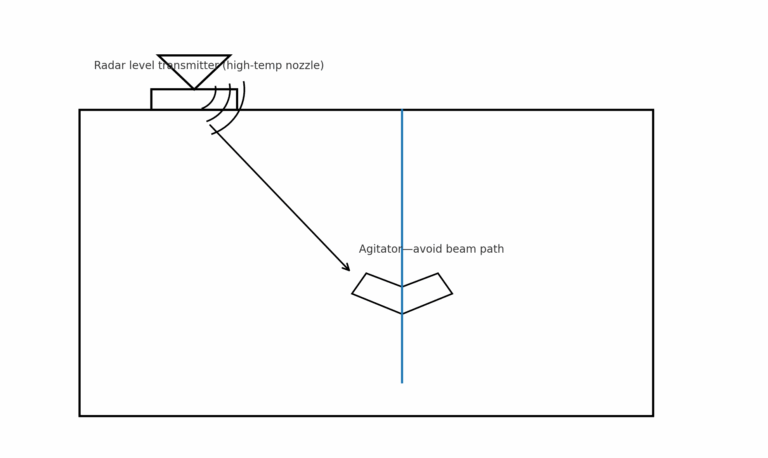

1) Non-Contact Radar Level Transmitters (Priority Option)

Why it works

Non-contact measurement: The antenna does not touch the medium; high-frequency radar reflections determine level, avoiding corrosion or thermal deformation of wetted parts. Typical designs handle −40 to 400 °C, and special versions can reach ≈600 °C.

Sealed compatibility: Flanged/threaded process connections maintain tight sealing and suit high pressure (up to ≈40 MPa) and volatile service.

Strong interference immunity: Less affected by viscosity, dust, and steam—useful when hot media generate vapors or mist.

Installation notes

Mount away from agitator blades, inlets, or internal structures that may cause false echoes; ensure a clear beam path.

For aggressive/high-temp service, choose Hastelloy or ceramic antennas.

Schedule periodic checks so transmitter output remains stable despite thermal stress on electronics.

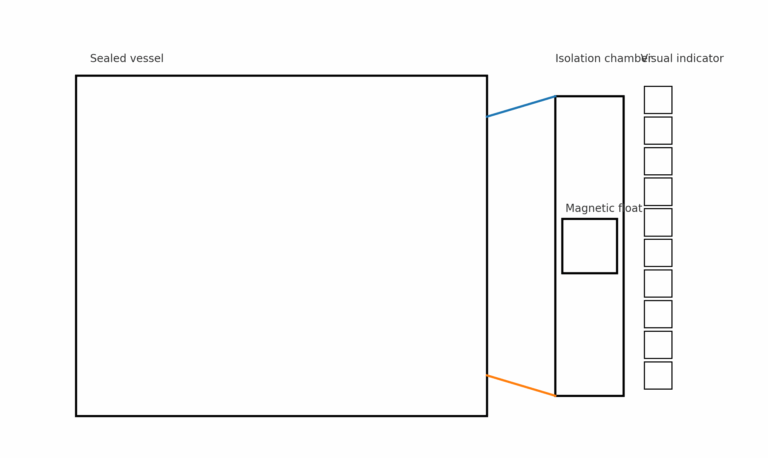

2) Magnetic Level Indicators (MLI) for On-Site Visual Reading

Why it works

Sealed and robust: An isolation chamber + magnetic float keeps the process sealed while the external indicator flips tiles to display level—no wetted display parts, minimal leak paths. Typical ratings ≈150 °C, with special linings up to ≈450 °C.

No power needed: Clear, walk-by visibility (red/white flip tiles) and optional remote modules; good for hot service with frequent operator rounds.

Installation & maintenance notes

Avoid mediums with strong ferromagnetic particles that may attract the float and cause sticking.

Check graphite gaskets periodically at temperature to prevent aging/leak risk.

Match float materials to media (e.g., SS for hot oils; titanium for corrosive high-temp fluids).

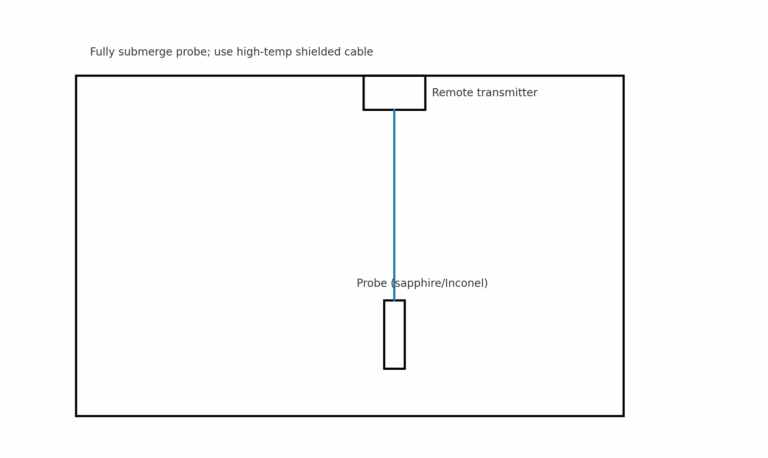

3) Submersible Capacitive / Hydrostatic Probes (Tight Spaces, High Accuracy)

Why it works

Compact geometry: The probe drops directly into the vessel or a side port—handy on reactors with limited nozzle real estate.

High-temperature materials: Sapphire diaphragms and Inconel/high-temp alloys tolerate ≈200–500 °C with a sealed cable to a remote transmitter.

High accuracy: Up to ±0.1% for tight level control.

Installation & maintenance notes

Keep the probe fully immersed (away from vapor space) and off the sediment layer to prevent drift and damage.

Use high-temperature shielded cable (e.g., fluoropolymer insulation).

Clean the sensing surface regularly to remove deposits/scale.

Figure 3. Submersible probe with high-temp shielded cable and remote transmitter.

Quick Selection Hints

Most sealed, hot, and “vapor-rich” services: start with non-contact radar; add proper antenna material and mindful nozzle placement.

If operators need local visual indication without power: consider an MLI with the correct float/gasket materials.

For cramped nozzles or tight control: a submersible capacitive/hydrostatic probe with high-temp materials and remote electronics is a strong fit.