1) Thread Connections (Abbreviations & Meanings)

| Abbrev. | Full Name | Standard / System | Notes |

|---|---|---|---|

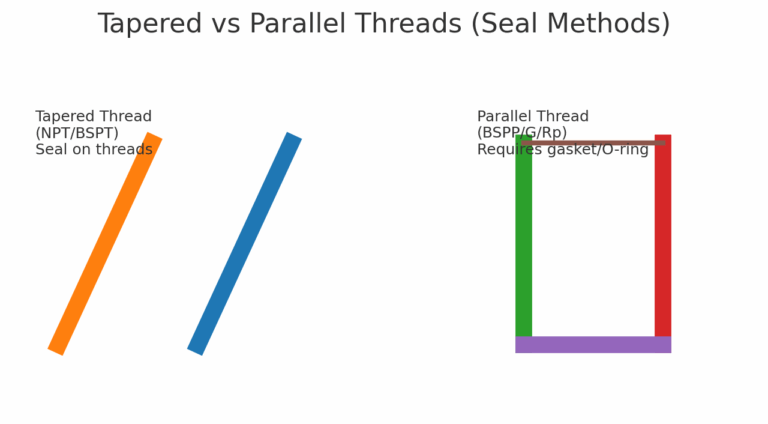

| NPT | National Pipe Taper | ANSI/ASME B1.20.1 | Tapered pipe thread; seals on the threads. |

| NPTF | National Pipe Taper Fuel | ANSI/ASME | “Dry-seal” tapered thread; enhanced leak-tightness for fuels/gases. |

| BSPT | British Standard Pipe Taper | BS | Tapered pipe thread; widely used in UK/Commonwealth. |

| BSPP | British Standard Pipe Parallel | BS | Parallel pipe thread; needs O-ring or gasket to seal. |

| G | “Gas” Parallel Thread | ISO 228 / BS | Parallel thread to ISO; common for low-pressure liquids/gases. |

| Rc | Rc Taper Thread | JIS B 0203 | Tapered pipe thread per JIS. |

| Rp | Rp Parallel Thread | JIS B 0203 | Parallel pipe thread; uses gasket. |

| M | Metric Thread | ISO / GB/T | Metric thread designation (e.g., M20×1.5). |

| PT | Pipe Thread | JIS B 0203 | Common for gas/liquid piping in JP/CN markets. |

Seal rule of thumb: Tapered = thread seal; Parallel = gasket/O-ring

2) Flange Connections (Abbreviations & Meanings)

| Abbrev. | Full Name | Standard / System | Notes |

|---|---|---|---|

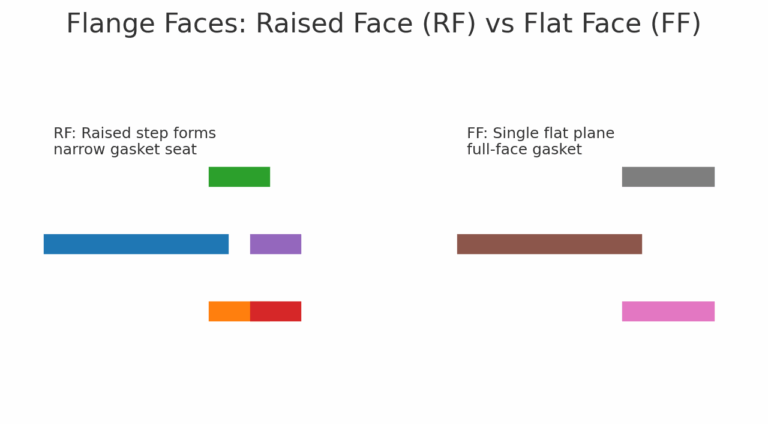

| RF | Raised Face | ANSI/ASME B16.5 | Raised sealing land for ring gasket. |

| FF | Flat Face | ANSI/ASME B16.5 | One flat plane; typically full-face gasket. |

| SO | Slip-On | ASME B16.5 | Pipe slips into hub; fillet weld. |

| WN | Weld Neck | ASME B16.5 | Butt-weld neck; high pressure/temperature capability. |

| SW | Socket Weld | ASME B16.11 | For small bore, higher pressure; fillet weld at hub. |

| BL | Blind | ASME B16.5 | Blank flange for line ends/covers. |

| SORF | Slip-On Raised Face | ASME | Slip-on with RF face designation. |

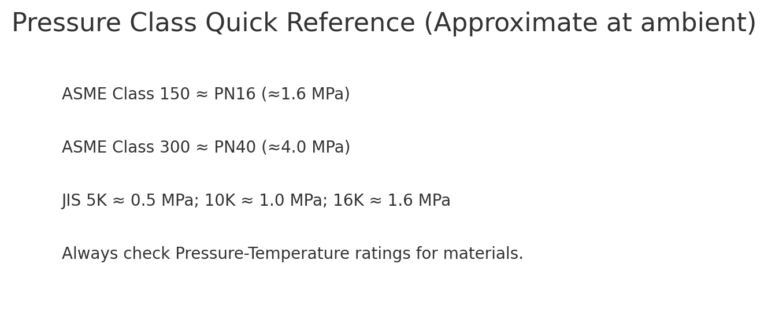

| CL150 | Class 150 | ASME | Pressure class (≈ PN16 / 1.6 MPa at ambient, indicative). |

| CL300 | Class 300 | ASME | Pressure class (≈ PN40 / 4.0 MPa at ambient, indicative). |

| PN | Pressure Nominal | GB/T 9112 | Nominal pressure rating (MPa). |

| JIS 5K/10K/16K | Japan Industrial Standard | JIS B 2220 | JIS pressure series; 5K≈0.5 MPa; 16K≈1.6 MPa. |

| JIS RF / JIS FF | JIS face types | JIS | JIS raised/flat faces. |

| GB | Chinese Standard Flanges | GB/T 9112/9113/12228 | e.g., GB/T 9112-2000 PN1.6 MPa RF. |

| DIN | German Standard Flanges | DIN 2573/2631 | Common PN16, PN25, etc. |

| BS | British Standard Flanges | BS 10 / BS 4504 | Legacy BS series; imperial compatibility. |

3) Common Combination Examples

DN40, PN16, RF → Nominal bore 40 mm, PN 1.6 MPa, Raised Face flange.

NPS 1½”, CL150, SORF → 1½-inch ASME size, Class 150, slip-on raised-face flange.

Rc 1″, JIS 10K, RF → JIS Rc 1″ tapered thread with 10K flange, RF face.

4) Selection Considerations (What to check before ordering)

Match standards end-to-end (threads & flanges from one system).

Pressure class: map ASME “Class” to PN/K only as a quick approximation; always verify against material-specific Pressure-Temperature ratings.

Sealing: tapered threads seal on the threads; parallel threads/flanges need gasket or O-ring.

Mixed notation (e.g., DN + 150#) appears in CN projects but the pressure class is still ASME.

5) Summary

Mastering these abbreviations and cross-system nuances helps you: quickly identify thread/flange types, avoid mismatched interfaces in the field, and communicate specs precisely in bids and drawings.