1. Overview

Programmable Logic Controllers (PLCs) are the backbone of industrial automation. When functional safety is part of the requirement, however, a Safety PLC is fundamentally different from a Standard PLC in design objectives, diagnostics, redundancy, and certification. Understanding these differences helps engineers select the right architecture, control lifecycle cost, and meet compliance.

2. Safety PLC: Design and Features

Definition. A Safety PLC is purpose-built to execute safety-related functions—e.g., emergency stop, light-curtain/guard-door monitoring—under functional safety standards such as IEC 61508/IEC 61511, and is typically third-party certified for a target SIL/PL.

Key characteristics

Safety-centric architecture. Implements systematic measures and diagnostic coverage to bring or keep equipment in a safe state upon detected faults.

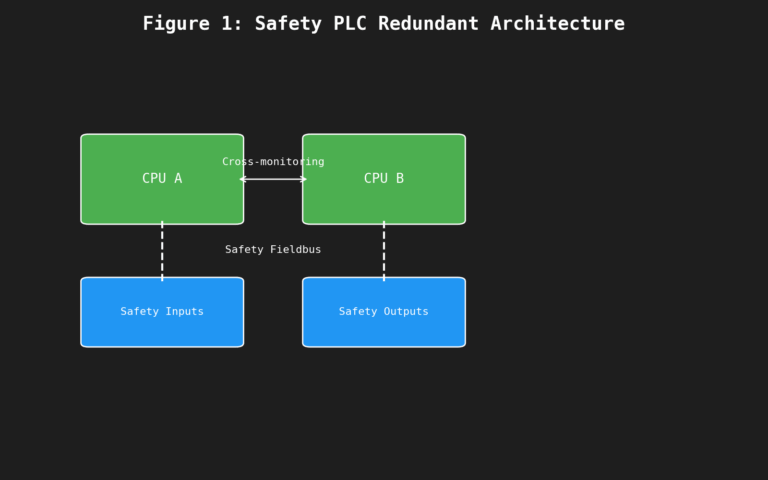

Redundancy & fail-safe operation. Often employs redundant processors and/or I/O channels with cross-monitoring, ensuring fault tolerance and predictable safe reaction.

Certified safety I/O. Inputs/outputs are designed and validated for safety tasks (e.g., E-Stops, interlocks, speed monitoring).

Deterministic reaction. Optimized for rapid, predictable response to hazardous conditions (qualitative claim; exact figures depend on model and configuration).

Compliance evidence. Delivered with certification artifacts to support safety validation and audits.

3. Standard PLC: Design and Features

Definition. A Standard PLC is a general-purpose industrial controller for sequence control, analog regulation, motion/drive coordination, and communications. It is not intended to natively implement safety-related functions to a certified SIL/PL without external safety measures.

Key characteristics

Versatile control. From simple machines to complex production lines, supports rich application logic and broad protocol coverage.

Programming flexibility. Ladder, FBD, ST, etc., with wide library/ecosystem support.

Cost-effective. Lower hardware and engineering cost where functional safety is not a requirement or is handled by external safety devices.

4. Key Differences (Side-by-Side)

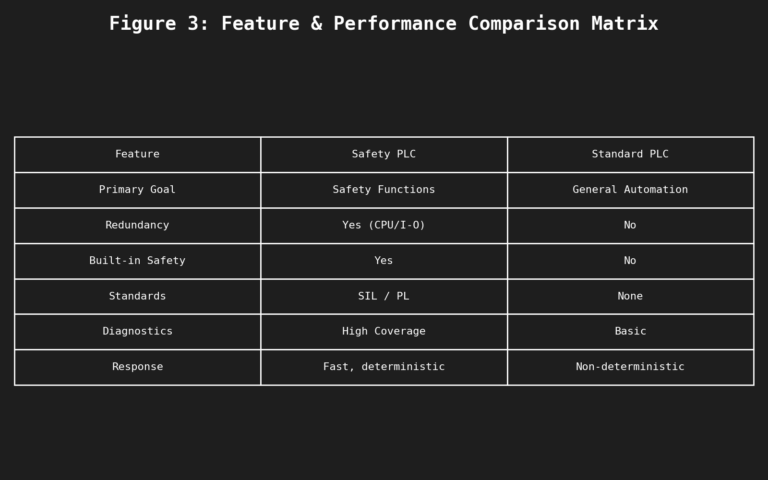

| # | Safety PLC | Standard PLC |

|---|---|---|

| 1 | Primary goal: protect people, machinery, process, and assets under defined safety standards | Primary goal: general automation and productivity |

| 2 | Redundancy: commonly in CPU and/or I/O with cross-checks | Typically no built-in redundancy for safety |

| 3 | Built-in safety functions: E-Stop, guard door, light curtain, safe speed/torque interfaces (model-dependent) | No built-in safety functions; relies on external or separate safety systems |

| 4 | Standards & certification: targets SIL/PL with third-party certification | No functional-safety certification required/claimed |

| 5 | Diagnostics: high coverage; designed to reach/maintain safe state on fault | Diagnostics oriented to availability, not certified safety |

| 6 | Reaction: fast, deterministic response to hazards (within validated constraints) | Response not validated to safety integrity targets |

5. Integrating Safety PLCs and Standard PLCs

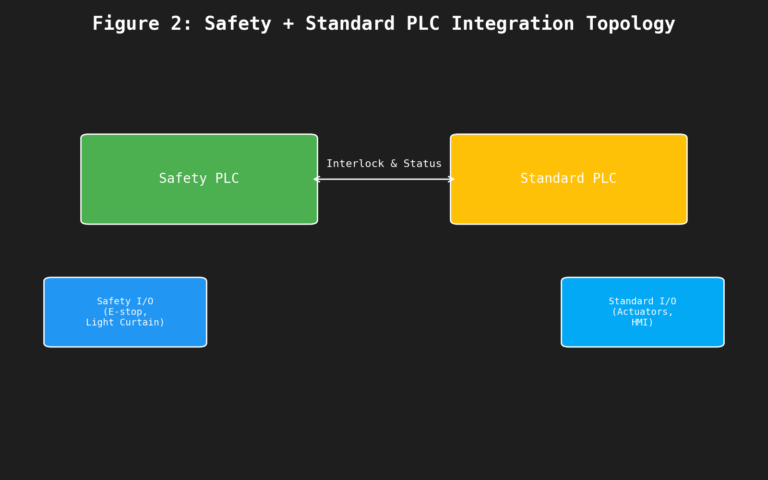

In many systems, a hybrid architecture leverages a Safety PLC for safety functions and a Standard PLC for general control. This provides robust protection while preserving flexibility and cost efficiency. Typical patterns include:

Safety interlocks (managed by Safety PLC) gating motion/sequence control (handled by Standard PLC).

Emergency stop handled by Safety PLC to force a safe state; restart sequencing coordinated by the Standard PLC after safety reset.

Separated networks: Safety-rated fieldbus for safety I/O; standard industrial Ethernet/fieldbus for non-safety I/O.

Clear interfaces: Well-defined handshakes so safety events override standard control deterministically.

Important: A Standard PLC must not be used to dilute, bypass, or delay safety reactions. Safety-critical decisions remain within the Safety PLC domain; the Standard PLC reacts to status and resumes only after safety conditions are satisfied.

6. Selection Guidelines

Use the following decision path to pick the right controller mix:

Risk Assessment (SIL/PL target).

If the hazard analysis demands SIL/PL for one or more safety functions → Safety PLC required (or certified safety devices).

Functional Scope.

If you need integrated safety logic (E-Stop, guard doors, safe motion inputs) with validated diagnostics → Safety PLC for those functions.

For non-safety tasks (sequencing, data handling, SCADA interface) → Standard PLC.

Lifecycle & Compliance.

Consider certification evidence, proof tests, documentation, and change control demanded by standards/regulators.

Cost vs. Consequence.

Balance hardware/engineering cost against the risk of harm and downtime. Safety PLCs cost more, but mitigate high-consequence events.

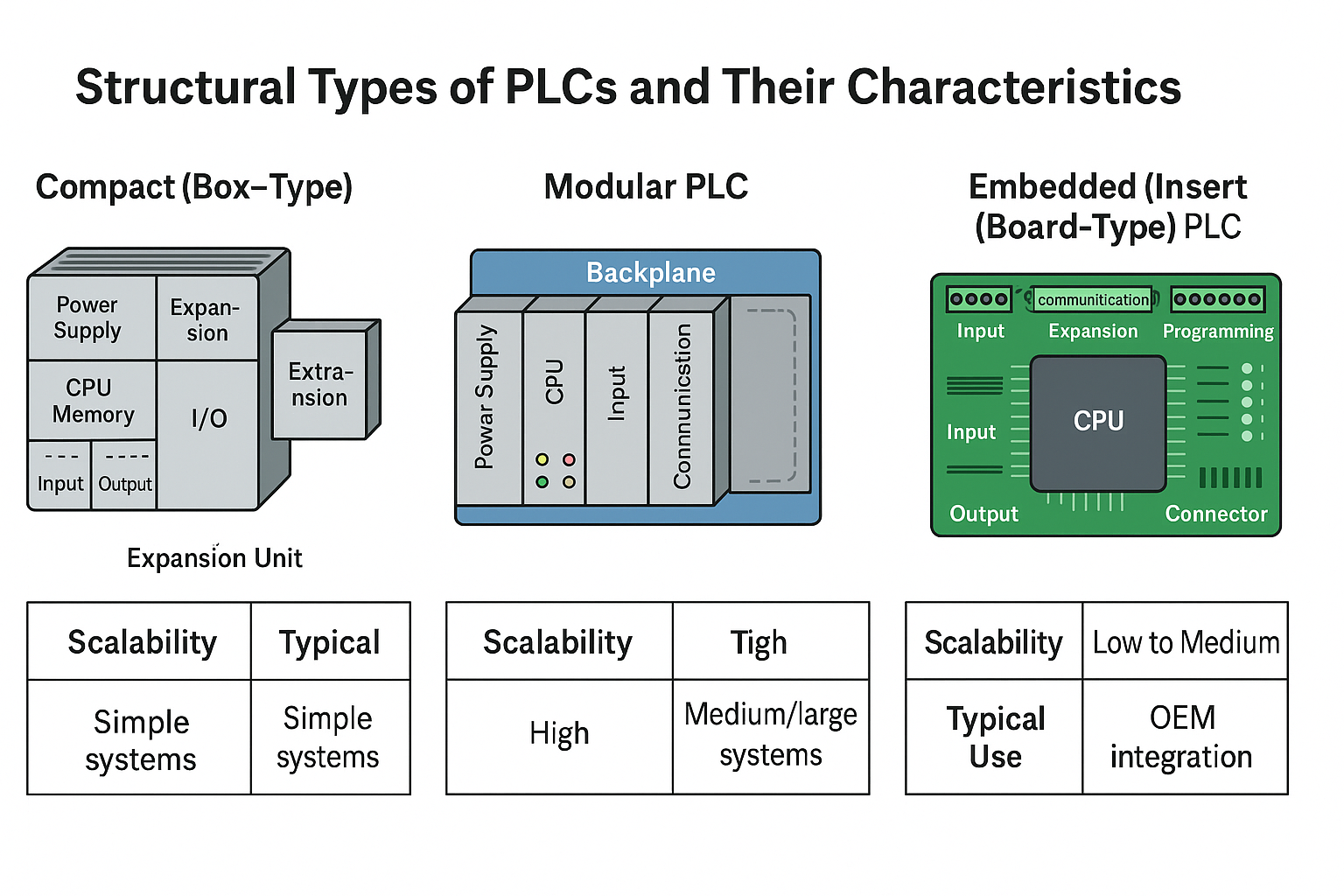

Future Scalability.

Plan I/O expansion, network segmentation (safety vs. standard), and maintainability (proof-test intervals, spares).

7. Common Pitfalls & Best Practices

Pitfall: Treating safety logic as “just another program.”

Best practice: Maintain separation of safety and standard logic, with change control and verification aligned to SIL/PL targets.Pitfall: Mixing uncertified I/O into safety chains.

Best practice: Use certified safety I/O and observe wiring rules (e.g., redundancy, test pulses).Pitfall: Incomplete diagnostics and proof testing.

Best practice: Define proof-test intervals, diagnostic coverage, and acceptance criteria consistent with the target SIL/PL.Pitfall: Unclear restart/recovery after a safety trip.

Best practice: Specify deterministic restart sequences and human-machine interfaces that avoid unsafe restarts.

8. Conclusion

A Safety PLC is engineered for functional safety, providing redundancy, diagnostics, and certified performance under standards like IEC 61508/61511. A Standard PLC excels at broad automation tasks but does not substitute for a certified safety function. The optimal architecture often combines both—Safety PLC for hazard control, Standard PLC for productivity—bound by disciplined interfaces and documentation.