Introduction

In high-hazard industries such as chemicals, power, and oil & gas, Safety Instrumented Systems (SIS) are a critical layer of protection. Yet terms like SIS, SIF, and SIL are often mixed together. This article provides a neutral, practical overview: what each term means, how they relate, how SIL levels differ, and when SIL 3 is justified.

Core Definitions

Safety Instrumented System (SIS)

A SIS is the dedicated hardware + software that monitors process risk and executes safety actions to prevent or mitigate hazardous events. It typically includes sensors, a logic solver, and final elements (e.g., shutdown valves).

Safety Instrumented Function (SIF)

A SIF is one specific safety function implemented by the SIS to keep the process safe—e.g., high-pressure trip that closes an emergency shutdown valve.

Safety Integrity Level (SIL)

SIL is a performance target for a SIF that reflects how reliably it must act when demanded (or over time, for continuous modes). Higher SIL ⇒ higher risk reduction and lower tolerated dangerous failure rates.

How SIS, SIF, and SIL Fit Together

Start with hazard identification (e.g., HAZOP) and risk evaluation (e.g., LOPA).

For each hazardous scenario requiring risk reduction, define a SIF.

Assign a SIL to that SIF, based on the risk gap that must be closed.

Engineer and verify the SIS so that each SIF meets its SIL target through architecture, diagnostics, proof testing, and management procedures.

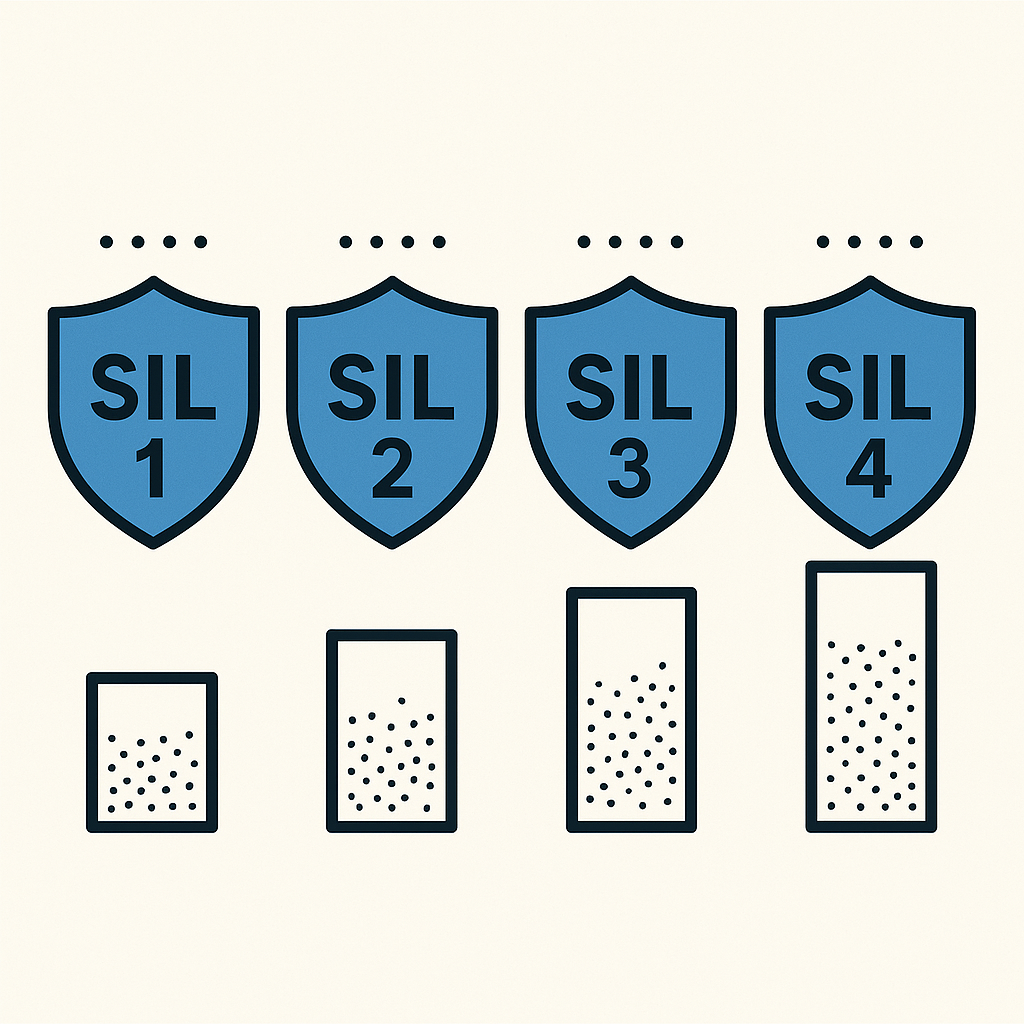

SIL Levels at a Glance

| SIL Level | Typical Use Case (qualitative) | What It Implies (qualitative) |

|---|---|---|

| SIL 1 | Lower-risk scenarios | Basic risk reduction with modest integrity |

| SIL 2 | Medium-risk scenarios | Higher integrity and more rigorous lifecycle |

| SIL 3 | High-risk scenarios | Very high integrity, architectural redundancy |

| SIL 4 | Extreme/rare cases in process industry | Exceptional integrity; seldom justified in process sector |

Note: Exact numerical targets (PFDavg/PFH) come from applicable standards and calculation results for the specific application.

About “Low-Integrity” Safety Functions

In practice, not all protective actions require the rigor of a SIS. Some low-integrity functions can be adequately handled by the basic process control system (BPCS) or procedural/physical measures when the required risk reduction is small. The key is that the required risk reduction (and consequences) must justify whether a function becomes a SIF with a SIL target, or can remain a lower-integrity protection.

When Does SIL 3 Make Sense?

Appropriate Scenarios

High consequence + credible frequency hazards where other protection layers are insufficient.

Cases where risk reduction needed for a single function is large, and combining multiple independent layers still leaves a gap.

What You Should Expect

Redundant architectures (e.g., 2oo3 sensors, 1oo2 final elements) to reach the integrity target.

Stricter proof test intervals and diagnostic coverage.

Documented competence, configuration control, and change management throughout the safety lifecycle.

Practical Trade-offs

Cost & Complexity: Higher SIL means more hardware, more verification, and more lifecycle work.

Maintainability: Proof testing and bypass management become operational realities—plan them early.

Diminishing Returns: Don’t “over-specify” SIL. Use LOPA and good engineering judgment to justify the target with the minimum necessary complexity.

Common Misconceptions (and Clarifications)

“Buy a SIL 3 device and you’re done.”

SIL applies to the function, not just a single device. A “SIL-capable” component helps, but the overall SIF architecture, diagnostics, and proof testing determine whether the SIF meets SIL 3.“Higher SIL is always safer.”

Only when justified. Over-engineering can create operational risk (maintenance burden, spurious trips) without meaningful additional safety.“BPCS trips are SIFs by default.”

Not necessarily. A trip in the control system can be part of risk reduction, but it isn’t a SIF unless it is designed, verified, and managed per the functional safety lifecycle to meet a SIL target.

Practical Implementation Checklist

Define the Hazard & Target

HAZOP scenarios, consequence/frequency, tolerable risk criteria.

Select Protection Layers

Credit alarms, physical safeguards, relief devices, BPCS, and SIFs (only if needed).

Assign SIL per SIF

Use LOPA (or equivalent) to quantify required risk reduction.

Engineer the Architecture

Sensors/logic/final elements, redundancy voting, diagnostics, proof test intervals.

Verify & Validate

Calculations (e.g., PFDavg/PFH), independence check, systematic capability, FAT/SAT.

Operate & Maintain

Proof testing, bypass management, impairment tracking, competence upkeep.

Manage Change

Configuration control, periodic re-validation, incident learning.

Conclusion

SIS is the system, SIF is the specific protective function, and SIL is the target integrity the SIF must achieve.

SIL 3 is justified for high-risk scenarios—not as a default specification.

Sound practice combines independent protection layers, defensible SIL assignment, and lifecycle discipline to achieve safety with clarity, maintainability, and value.